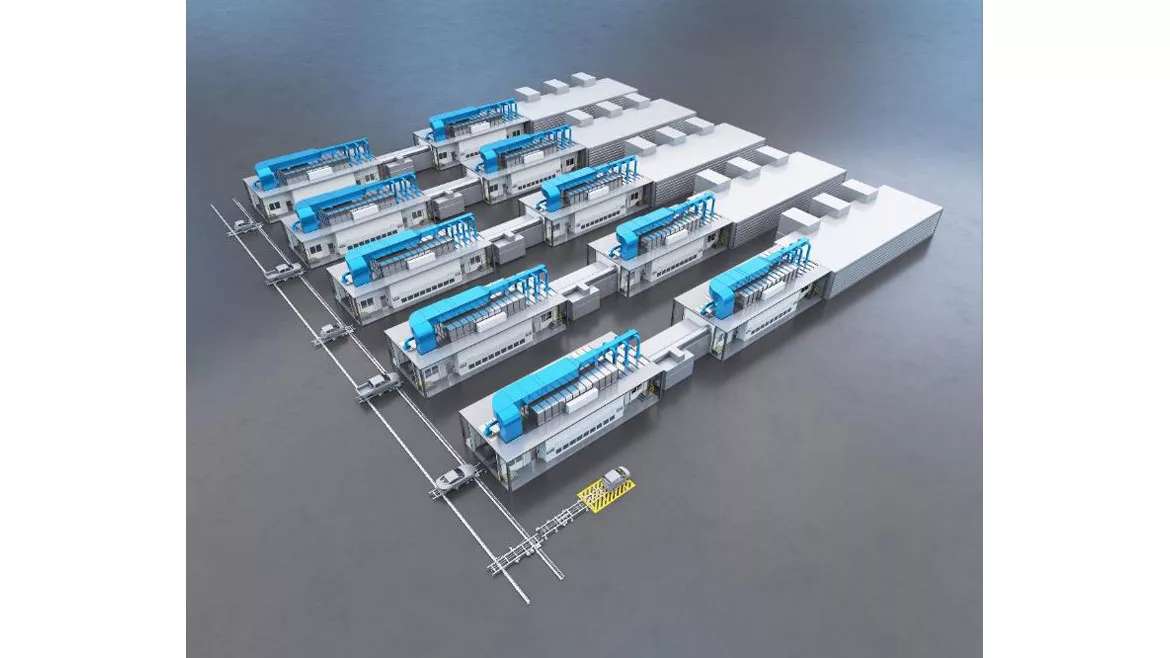

Spray Booth from Dürr

SOUTHFIELD, MI — The EcoProBooth from Dürr opens up new perspectives in spray booth technology for car manufacturers. With its modular box concept, independent lines and the combination of interior and exterior painting in a single box, it reportedly provides a degree of scalability and flexibility previously only possible for small-scale series. However, this is not the only way it meets essential requirements for future production. With its new booth concept, Dürr also addresses the critical topic of energy efficiency. Compared to current line concepts with dry separation, the EcoProBooth promises to reduce energy consumption by around 40% and carbon emissions. For the many existing systems that will continue to operate with wet scrubbing, the savings will increase to 75%.

EcoProBooth boxes can transform individual painting lines into an efficient and flexible painting environment. The example of a primerless process clearly illustrates this. In this case, an integrated paint process (IPP) for 60 jobs per hour (eight zones for base coat and six zones for clear coat, traditionally split between two rigid lines with 30 jobs per hour each) became five parallel EcoProBooth lines. Each features one position for all base coat applications and one for all clear coat applications. Fourteen zones became 10 boxes. Each line can be individually controlled and brought online or offline as needed.

Scalability for System Efficiency

Greater efficiency is also ensured by the optimal distribution of the bodies to the EcoProBooth boxes. Cycle time losses due to different painting scopes, such as metallic and solid, or different body types are a thing of the past. The greatest painting scope no longer determines the cycle, since the booth size paints all standard passenger car types – from compact cars to SUVs. The size and design of the box are standard. This means straightforward conversions and extensions are possible without a knock-on effect on production in other box segments.

All-in-One for Greater Availability

The painting robots look after the interior and exterior painting in one box using the application technology optimally coordinated to the body in question. The new EcoBell4 Pro Ux universal atomizer reportedly meets the highest standards for painting quality and ensures that only four painting robots are needed per box. Integrating all the painting tasks into one box eliminates the time required to convey bodies, when the robots are inactive, between the process steps for interior and exterior painting.

Another factor in the uninterrupted operation of the system is the service cubicles located in the corners of the booth, which have a continuous flow of fresh air through them. Employees can safely access them — without a breathing apparatus — to clean or do minor servicing tasks on atomizers and tools while painting continues. At the same time, the amount of cleaning required can be adapted to the degree of contamination of the respective component using the DXQ software from Dürr.

Maximum Air Recirculation Means Low Energy Consumption

The highly efficient modular concept has enabled Dürr to reduce the booth area. In the example mentioned, the volumetric flow rate of the process air is around 20% lower. The modular concept minimizes energy consumption and reduces carbon emissions and operating costs.

The EcoProBooth has a highly recirculated air rate thanks to its low energy needs with a ratio of recirculated air to fresh air of 95:5. This means the process air is supplemented with 5% fresh air, taken directly from the clean room without any additional air supply system. The box also features overspray separation with the latest generation of the EcoDryScrubber. Once the paint particles have been removed from the air, they are reconditioned in a recirculating air unit assigned directly to the painting booth, reducing energy consumption and costs. The new EcoDryScrubber can purify almost twice as much air as the predecessor models with just one filter stage per module. The highly compact design of the filter stage integrates perfectly into the box concept. Compared to a traditional wet separation system, Dürr reduces the energy needed by 40%. For a painting line with wet scrubbing, this increases to 75%.

Sustainable Investment

In addition to efficiency and flexibility, sustainability is an increasingly important competitive factor for the manufacturing sector. With its new system layout, Dürr has created the ideal conditions for needs-based manufacturing and efficient use of resources. Significant reductions in the volumetric flow rate of the process air and the high recirculation rate keep energy consumption and carbon emissions as low as possible. At the same time, the intelligent box layout reduces material consumption by cutting losses when changing color. Subdividing the line into shorter segments additionally allows for the intelligent distribution of painting orders to minimize color changes, saving paint and flushing agent consumption and reducing costs and VOC emissions.

EcoProBooth is suitable for major volume manufacturers or e-mobility newcomers. It offers savings whether building a new system or retrofitting an existing one.

Additional details are available at www.durr.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!