Vapor Degreaser Cleaning: Combatting High Energy Prices and Resource Consumption

The rising costs of energy are affecting commercial and industrial manufacturing companies across the globe. The unprecedented rise in natural gas, electricity and diesel isn’t expected to slow down anytime soon. Natural gas and electricity prices in Europe and Asia are at record highs, and U.S. prices are expected to double this year.1 The uncertain energy supply is negatively affecting production, and companies worldwide are under intense pressure to cut costs across manufacturing.2

There are opportunities for manufacturers to reduce energy consumption, including the obvious power guzzling culprits of heating, cooling and lighting. But there are other common sense production solutions where energy savings can be gained. One is parts cleaning.

Thorough cleaning is essential to creating parts with a high-quality, pristine surface that is ready for painting, powder coating or other finishing processes. But as manufactured parts get smaller and more intricate, the challenge of meeting the industry’s stringent quality standards is more difficult. Production debris like machining, stamping or cooling oils, dust, metal filings, marking inks, fingerprints and other soils must be removed. Any remaining particulate or residue can negatively impact the parts’ appearance or performance. The trick is to get parts clean in the most energy efficient and cost-effective way.

Vapor Degreasing: An Energy-Saving Cleaning Option

Vapor degreasing is one of the most energy-efficient and environmentally acceptable choices for parts cleaning and prepping. This is particularly true when compared to other parts cleaning methods including aqueous or water-based cleaning.

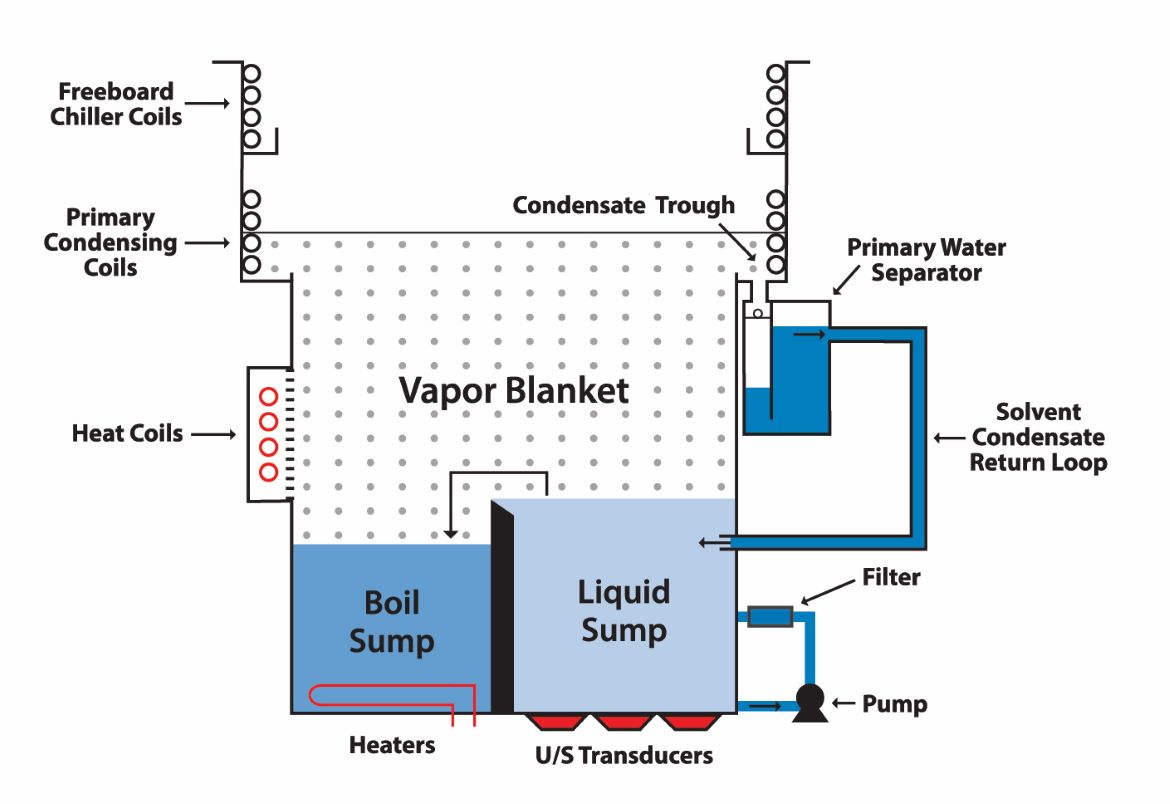

Vapor degreasing is a closed-loop system that cleans using a solvent-based cleaning fluid. The vapor degreaser has two chambers. In the first chamber, the cleaning fluid heats to a boil, which then generates a vapor cloud that rises to meet cooling coils at the top of the machine. These cooling coils cause the vapors to condense and return to their liquid state. This liquid is then channelled back to the second chamber, known as the rinse chamber.

Soiled parts are immersed in the continuously filtered and distilled cleaning fluid inside the first chamber to dissolve or lift the soils from the surface of the parts. They then transfer to the second chamber for a fluid rinse. As the parts are lifted from the rinse fluid, they undergo a brief vapor rinse and drying process. Any leftover cleaning fluid drips back into the vapor degreaser for filtering and reuse. After a typical cleaning cycle of around 6-20 minutes per batch, the parts come out clean, rinsed, dried and ready for painting or coating.

Vapor degreasing provides significant energy savings, especially when compared to aqueous cleaning systems that can be very energy intensive to run. Here’s a comparison.

Energy-Intensive Aqueous Cleaning

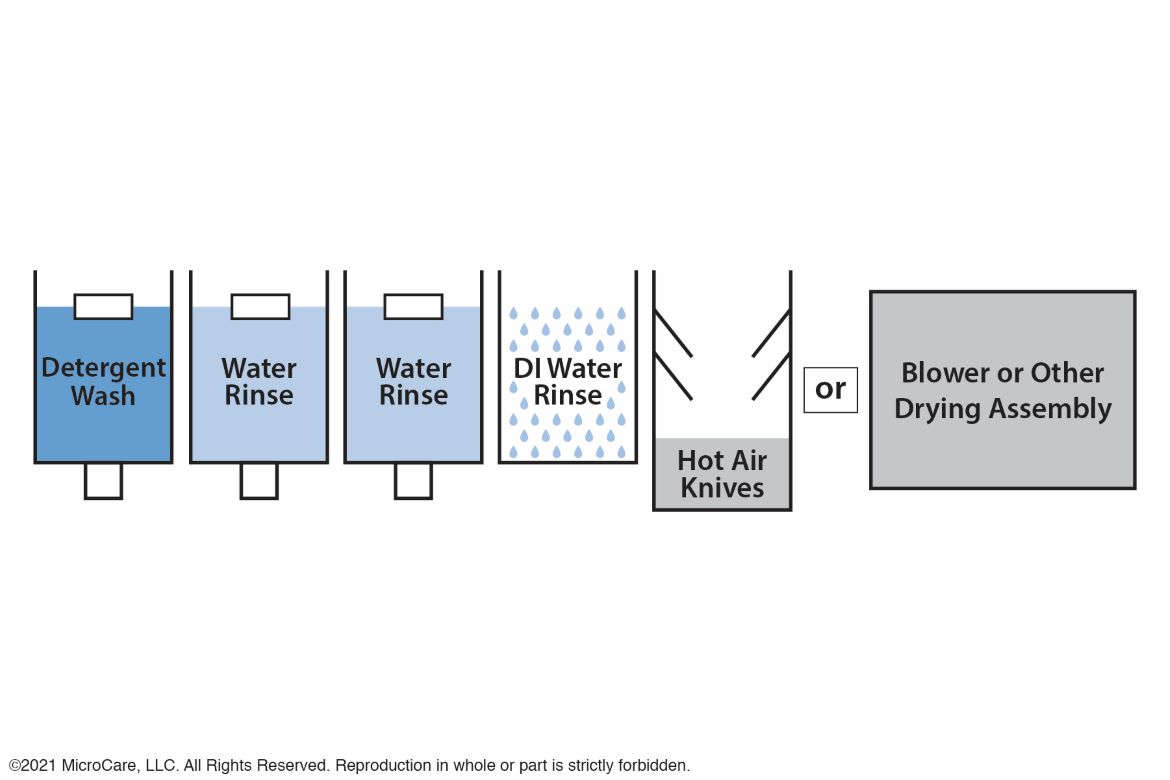

Most aqueous cleaner machines have horizontal layouts and use hoists or conveyors to move the parts through a series of dip tanks. A typical aqueous batch system has one wash tank and between two to five reverse-flow, cascading rinse tanks that require 2-5 gallons per minute of deionized water. Aqueous cleaner machines are typically 50-150% larger than vapor degreasers of the same capacity, simply because of the need for more tanks, larger pumps, blowers, filters and so on. Normally, these machines consume about 18-20kWh of electricity. Most aqueous cleaning systems have three or more tanks with ultrasonic excitation, adding another 1-2kWh of consumption. Also, aqueous system cleaning cycles tend to last 20-40 minutes.

There are six areas of aqueous cleaning systems that make them very energy-intensive. These are:

- Power to the numerous, high-pressure pumps that move the water around the machine, and the machines can be huge;

- The energy it takes to heat the cleaning water;

- The stand-by power draw;

- The energy it takes to dry the parts;

- The energy it takes to treat and purify the water for re-use or disposal;

- The energy it takes to cool and de-humidify the surroundings.

All of this additional work is required because of the inherent nature of the molecule of water. Basically, water has both a high surface tension and a high latent heat of evaporation. Consider these fundamental characteristics.

High surface tension is a problem for water cleaning. It stops the water from going into tight spaces. That’s why users first need (a) to heat the water, and then (b) then they need to use additives to boost the cleaning power and reduce surface tension, and finally they need (c) big pumps to spray the water-and-additive mix into tiny components.

Another consideration is the stand-by power draw. At some companies the aqueous systems are never shut down because of the cost of coming up to temperature and the delay in re-heating the water. So even when idle, aqueous systems will use a further 2-5 kWh of electricity at a minimum, hour after hour, even when no cleaning operations are being conducted.

Then, the high latent heat of evaporation makes water a slow-drying cleaner. In most instances, water must be completely removed from parts to prevent flash rusting or surface spotting from leftover residue. It takes a lot of heat and big, energy-drawing air knives to remove the aqueous residual from the components.

At this point, the water has picked up the contamination — in addition to the cleaning additives, the water may now be holding oils, greases, particulate and so on. That water, the additives and the contamination now must be treated in a waste-water treatment system to re-purify the water. Normal treatment facilities include reverse-osmosis systems and multiple stacks of de-ionizing filters. Obviously, this takes additional electricity and more pumps to move the wastewater through these cleansing processes.

Lastly, is the cooling and dehumidifying of the surrounding area. Aqueous cleaning typically adds moisture and some heat to the factory environment, requiring air conditioning to maintain the air humidity and temperature.

Energy-Efficient Vapor Degreasing

In general, modern, nonflammable vapor degreaser cleaning fluids have low surface tension, low viscosity, high density and low latent heat. This means they clean more easily, with less heating, fewer pumps, no air knives and so on. There is no water to heat, which saves electricity. Instead, the cleaning fluid heats to just above room temperature, which takes very little electricity. In addition:

- The cleaning fluid moves by gravity, so there are no big pumps required to push the cleaning fluid around, saving electricity;

- There are no blowers or “air knives” on vapor degreasers, which saves electricity. The cleaning fluid is retained inside the machine and the parts being cleaned come out dry. In fact, motorized fans and fume hoods are not recommended near vapor degreasers because it increases cleaning fluid losses, so electricity is saved there, too;

- No stand-by mode required;

- There is no waste treatment required, which saves electricity, because the degreaser is automatically, inherently and continuously re-purifying and re-distilling the solvent;

- There is no humidity added to the factory environment, so air conditioning and environmental loads are reduced.

The net result is that the typical vapor degreaser uses about 7kWh or power when cleaning and one-tenth of that energy in stand-by (night) mode; many of the smallest machines use standard household electrical connections. This contrasts with water-cleaning systems with power consumption is measured in hundreds and thousands of amps, and often require 440-volt circuits and big power panels to manage the electrical load. When compared, the energy savings of vapor degreasing are extensive.

This is Just the Beginning

Energy saving through vapor degreasing is just the beginning. Other savings, from faster throughput to higher yields and fewer defects all contribute to ever greater profitability. In a nutshell: with energy costs rising and the availability of adequate water supplies becoming a global concern, it makes sense to make the move to energy-efficient solvent cleaning. Vapor degreasing and progressive next-generation cleaning fluids provide successful critical cleaning that is energy efficient, better on the pocket and a long-term sustainable option.

For more information, visit www.microcare.com.

References

[1] https://www.cnbc.com/2021/10/08/natural-gas-prices-are-skyrocketing-globally-what-it-means-for-the-us.html

2 https://www.yuenergy.co.uk/energy-saving-manufacturing-warehousing-logistics-guide/

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!