Millwork Paint Operation Gains Visibility into Paint Usage

With Cloud-Based Flow Monitoring and Control System

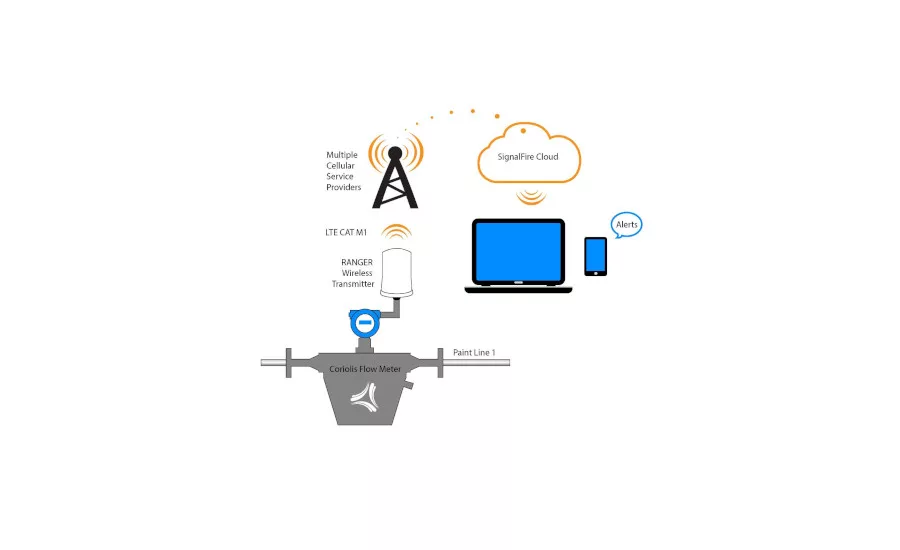

A TRICOR Coriolis mass flow meter attached to a SignalFire RANGER cellular transmitter offers a closed-based solution. The flow meter’s Modbus serial communication protocol interfaces with the Ranger which, in turn, periodically uploads data to the cloud.

To accurately measure the water-based paint used by the millwork operations, a TRICOR TCM 028K Coriolis flow meter measures paint flowing from paint totes, with data uploaded to a SignalFire RANGER cellular transmitter for viewing on a cloud-based dashboard.

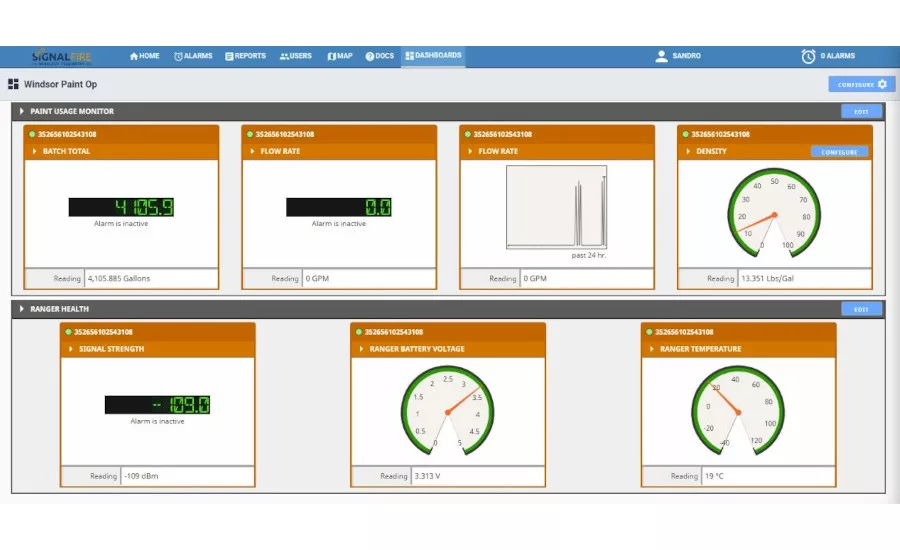

A wireless flow monitoring and control system offers customizable dashboards so operators can view critical data about paint usage, temperature, and flow rates on a PC or mobile device.

A producer of architectural wood trim gained visibility into paint consumption at its facility by installing a cloud-based flow measurement and control system that provides accurate and real-time data on paint usage, flow rates, density and other parameters from a computer or smart device.

The wood trim producer has two identical plants that paint trim using the same equipment, products and paint. Using a vacuum coating process, finished wood trim is dipped into a paint tank with excess suctioned off and returned to the tank. Production paint is sold in large 275-gallon containers called totes. Fresh paint is added to the tank from the totes to maintain appropriate volumes.

In the past, the translucent paint totes were visually gauged to determine paint levels. If half a tote was empty, operators estimated a 137.5 gallon of paint usage. While no instrumentation monitored or recorded paint levels, the manufacturer knew the number of paint totes and board feet painted at the plant. Combining paint consumption with board feet painted, the wood trim producer calculated costs at each plant and compared them. Expectations were that paint usage would be similar at each plant. However, operators noticed that one plant was consuming more paint than the other for similar board feet of trim. Executive management wanted to know why one plant used more paint than the other.

The manual system of gauging paint consumption by observing levels through the paint totes proved unreliable in providing an answer as paint measurement was imprecise and inconsistent. The plant also did not record consumption to get a historical perspective of paint usage. The millwork plant operation needed an accurate method of measuring paint consumption over time to ensure consistent metrics across operations.

Cloud-Based Solution Provides Remote Control

A wireless flow monitoring and control system offered an ideal and cost-effective solution to monitor paint consumption with greater accuracy and real-time feedback. It also provides a wireless interface to paint processes via a PC or a smartphone so operators can monitor the paint process remotely.

To track paint consumption, a TRICOR TCM 028K Coriolis mass flow meter was installed to measure the paint flowing from the totes. The gearless design of the Coriolis flow meter makes it ideal for this application, as paint can cause high friction or inhibit the moving parts of standard gear meters, causing measurement inaccuracies or even unit failure.

Because the manufacturer’s IT team was hesitant to integrate the flow meters onto their network, a cloud-based solution eliminated security risks and maintenance by internal staff. The simple and user-friendly system includes a Coriolis mass flow meter attached to a SignalFire RANGER cellular transmitter that communicates with the cloud. The TRICOR Coriolis flow meter’s Modbus serial communication protocol interfaces with the Ranger which, in turn, periodically uploads data to the cloud.

The RANGER transmitter quickly and easily attaches to the flow meter, providing power and connecting data to a cloud interface through an LTE-M cellular network. In fact, the Coriolis flow meters were delivered to the millwork plant attached to the RANGER transmitters to provide a plug-and-play paint metering solution. (The flow meter manufacturer never entered the plant during the entire installation!)

Real-Time Updates on Performance Data

Operators retrieve data on paint operations from a computer or smart device through the SignalFire Cloud web application. A customizable dashboard provides instant visibility on different operating parameters including flow rate, temperature, density and usage, as well as geographic location of the RANGER with the built-in GPS. Using the dashboard, operators can track paint consumption over a specified date range or by batch for business planning. In the past, the millwork plant did not have historical data or generate reports on paint consumption.

The Modbus serial communications interface also allows remote programming and support for the meter. During the pandemic, the ability to remotely support the cloud-based flow monitoring and control system and even change operating parameters of the TRICOR Coriolis meter proved important. Should any future problems occur, the plant manager can provide access to the flow meter company through their cloud account to troubleshoot issues without the expense of a service call.

In addition to gaining visibility into paint processes, the mill obtained a lower insurance premium by asking their local water authority to add a RANGER transmitter with an integral pressure transducer to monitor the water level in their water tower. Alarms are texted to the water authority and the mill’s managers if water levels (pressure) drop too low. The RANGER transmitter helps prove to the insurance company that optimum water pressure is maintained for the mill’s fire extinguishing system.

Since installed a year ago on one plant, the cloud-based flow measurement and control system proves essential in determining exactly how much paint is used during a period to support management decisions. They can schedule the change out of paint totes during downtimes instead of stopping production runs. Data is even usable to calculate VOCs (volatile organic compounds) per gallon for monthly EPA emission reports. The millwork producer is currently considering adding the same solution to its second plant for a complete network configuration.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!