Time is Money: Universal Matting of Powder Coatings in the Shortest Possible Time

Life moves quickly. Trends and customer requirements in industrial processes are changing in ever-shorter cycles. Particularly, contract coaters must be very flexible when responding to incoming customer orders. Many contract coaters therefore rely on keeping an extensive stock of different powder coatings. Of course, all the common systems, colors, textures and gloss values need to be considered. The disadvantage is that not every coater has access to large storage facilities and that this stock initially counts as fixed capital.

Alternatively, most powder coatings manufacturers have started to offer short delivery times. However, this method does not always guarantee that the required systems are available on demand. They may even still have to be manufactured. And this is getting even more difficult due to the fact that supply chains are currently unreliable and there are raw material shortages.

Powder coatings are time consuming to produce, and it is nearly impossible to alter their visual properties after the fact. Each powder coating, whether high gloss, semi-gloss or matte, must be produced entirely separately. This makes it a challenge for the manufacturer and for the coater to respond flexibly and in the shortest period of time on customer demands. Until now, the only option has been to keep as many powder coatings as possible in stock with a wide variety of different properties.

This article will describe an alternative option: a very simple, quick and completely label-free solution to meet the demand for different gloss values. This solution is available to powder coatings manufacturers but also to the coater, directly on the line.

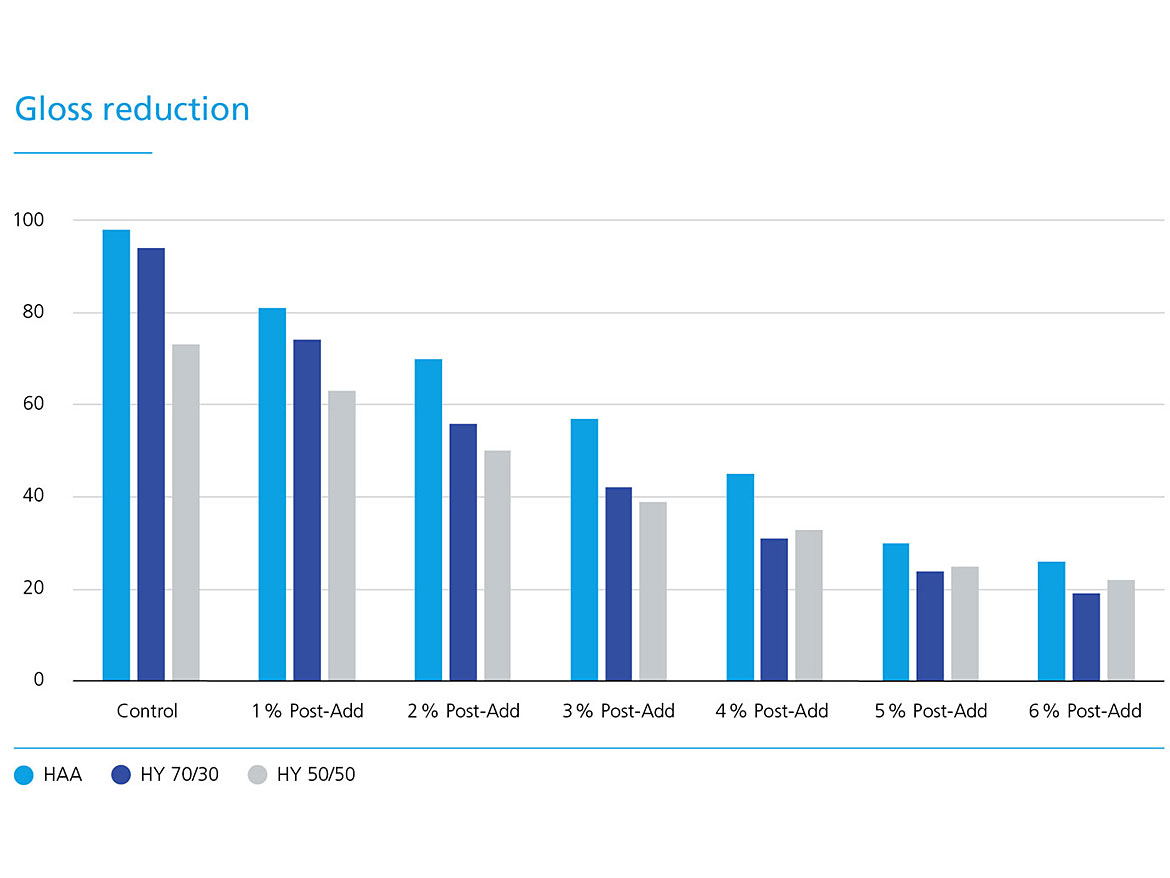

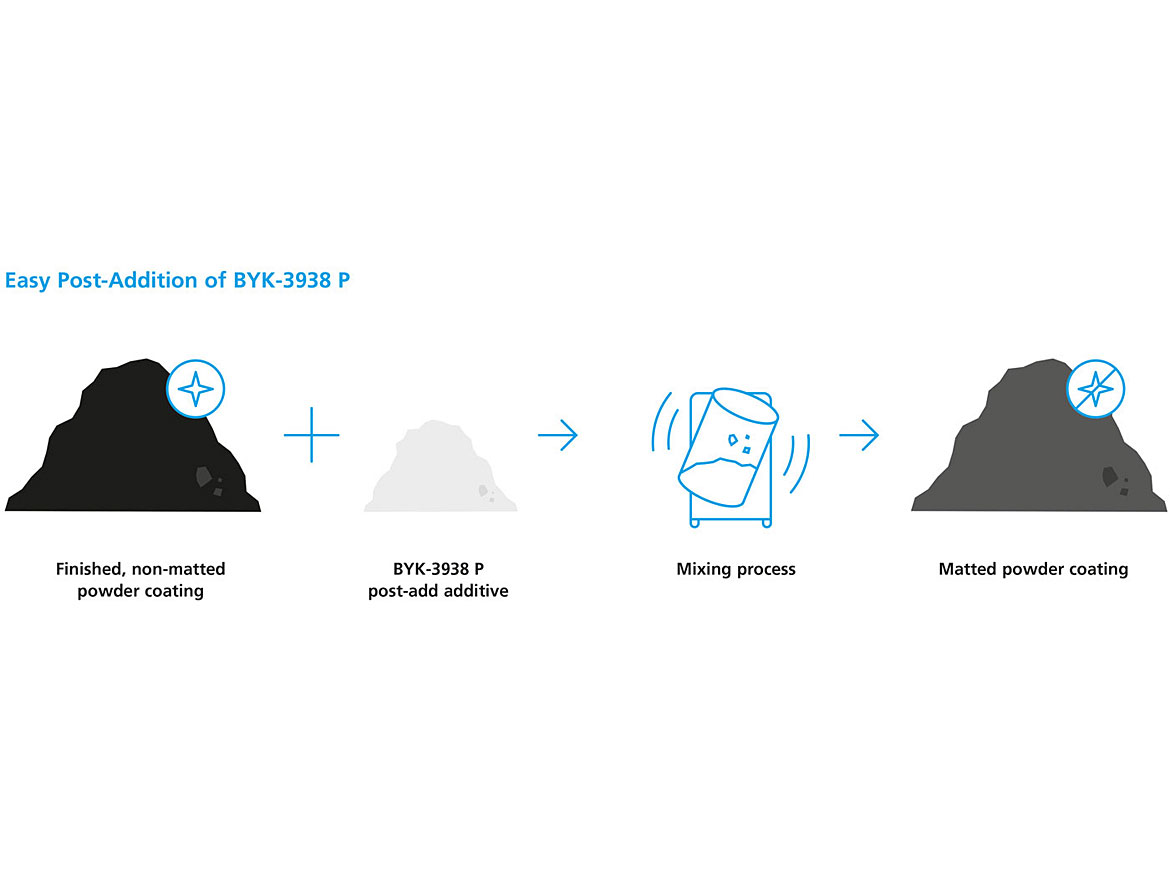

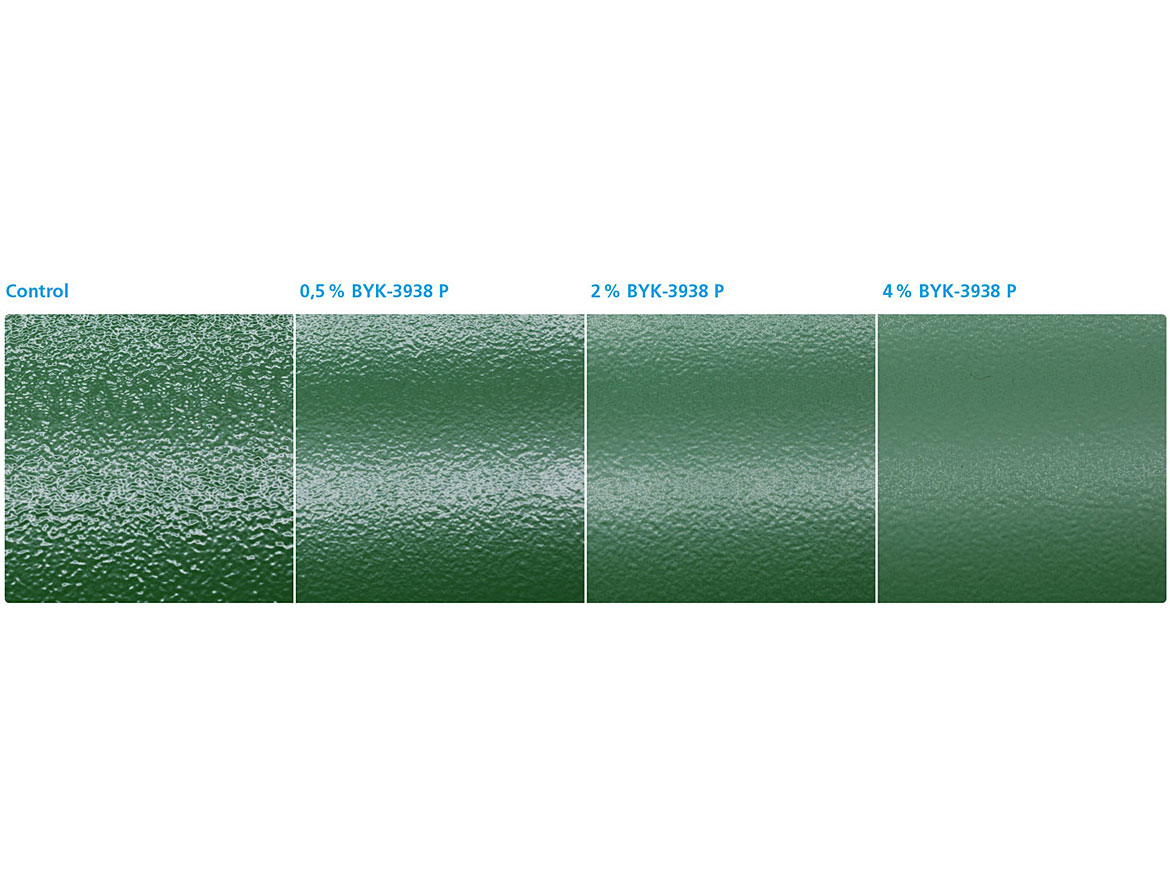

The novel additive BYK-3938 P allows all types of powder coatings to be matted flexibly and immediately (Figure 1). To do so, a homogeneous mixture simply needs to be created with the basecoat (post-blending principle). No extruder is therefore required for this work step. The mixing process can be carried out with a variety of devices such as a tumble mixer or any other suitable solid substance mixer.

HAA = weather-resistant powder coating based on polyester resin and Hydroxylalkylamide as hardener

HY = Hybrid powder coating for interior applications based on polyester resin and epoxy resin in the ratio 70:30 and 50:50

The finished compound can be applied in the coating line or simply stored under normal conditions. The additive is chemically inert and will not cause reactions with the powder coat. Therefore it has no effect on storage stability.

The additive can be used without considering stoichiometric ratios because the matting takes place through a physical process rather than a chemical one. The matting characteristics are controlled entirely by the additive dosage quantity on a virtually linear basis and regardless of the binder system chemistry.

Since the additive is label-free, there are no restrictions on application fields, and no special safety measures need to be taken. The regulatory status of the matted powder coatings does not change either.

How is the Additive Incorporated Into the Powder Coating?

Usage is exclusively through post addition and mixing with the finished powder coating (Figure 2). Incorporation of the additive into the powder coating by extrusion only results in minimal gloss reduction and is therefore not recommended.

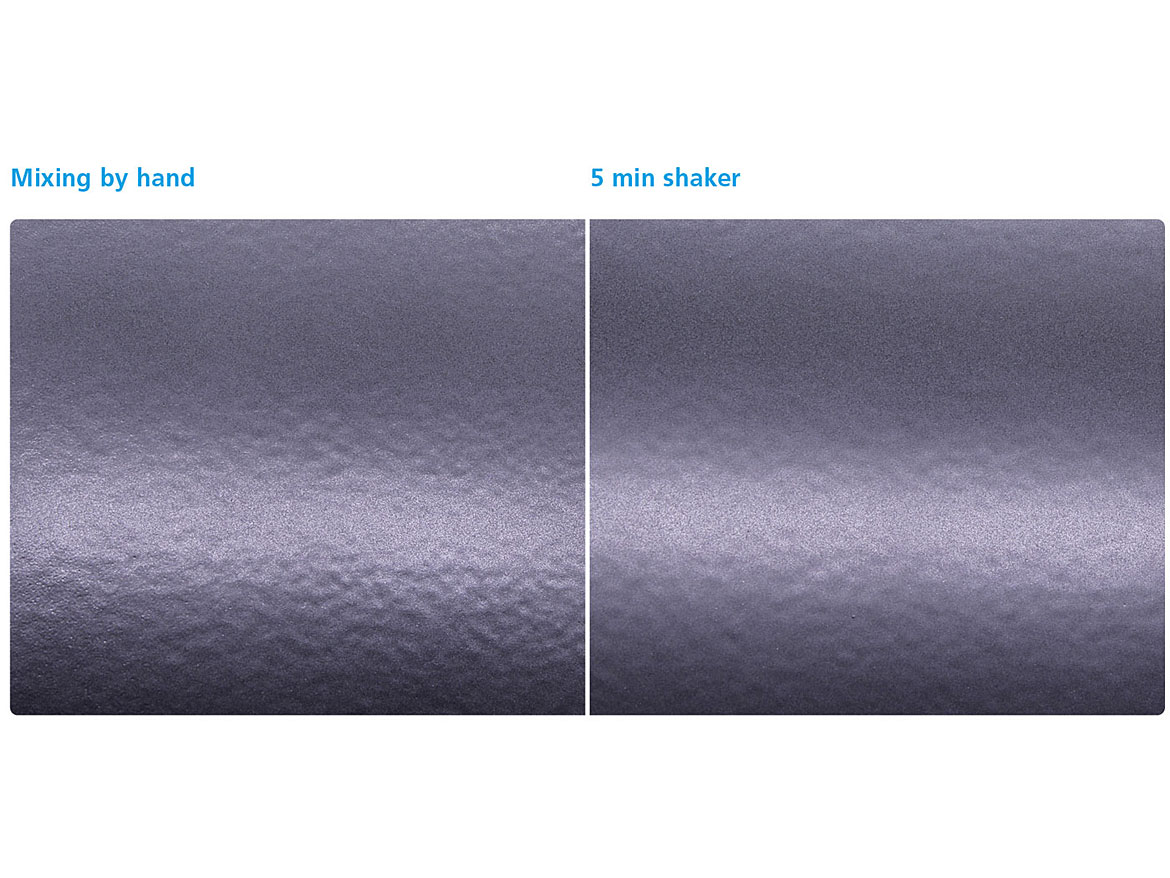

The additive does not require high shear forces to be mixed with the powder coating. However, the better and more thorough the incorporation is, the better the appearance of the resulting coating. Figure 3 shows a comparison of different mixing qualities at a dosage of 4%. Left, briefly by hand and right, 5 minutes with a laboratory shaker. A significant improvement in surface quality can be achieved by better incorporation. The high homogeneity of the mixture results in better leveling properties.

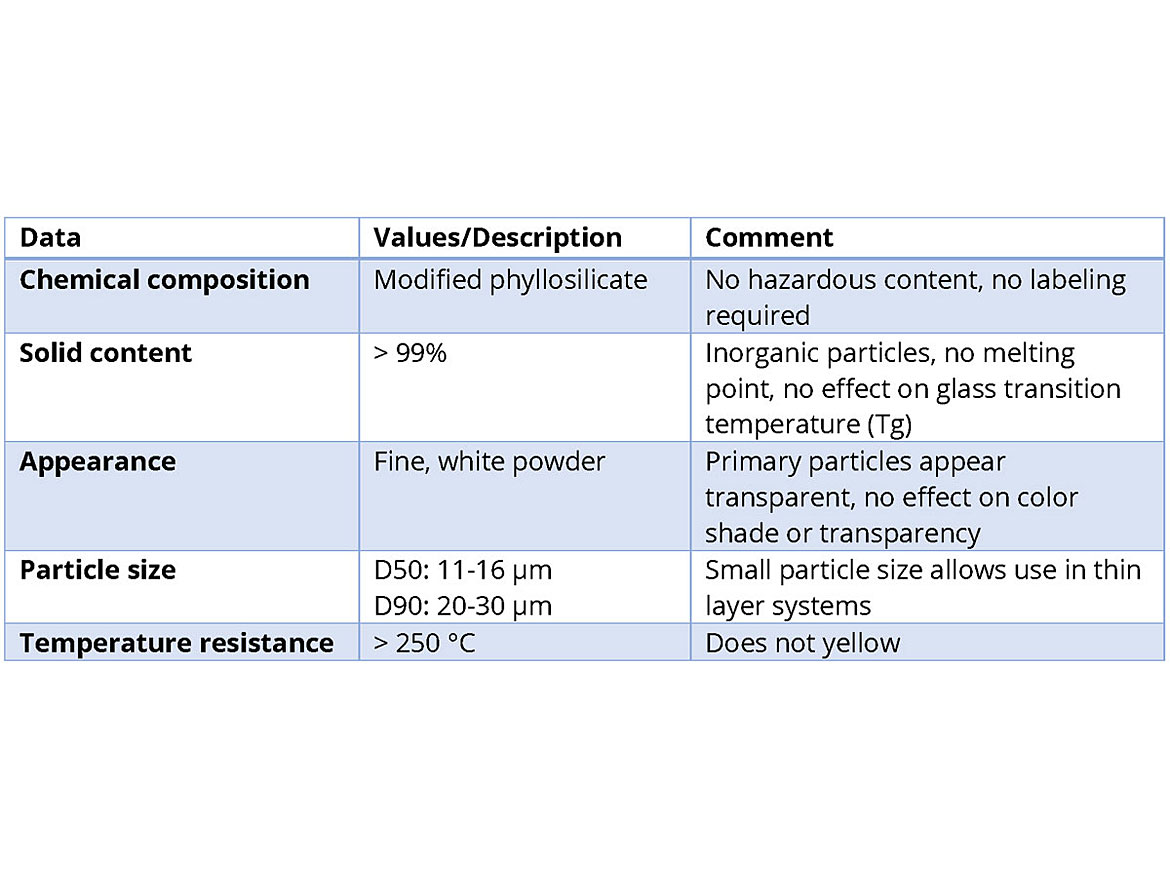

Properties

Table 1 shows an overview of the properties of BYK-3938 P.

Matting Effect

Theoretical Description of Gloss Reduction

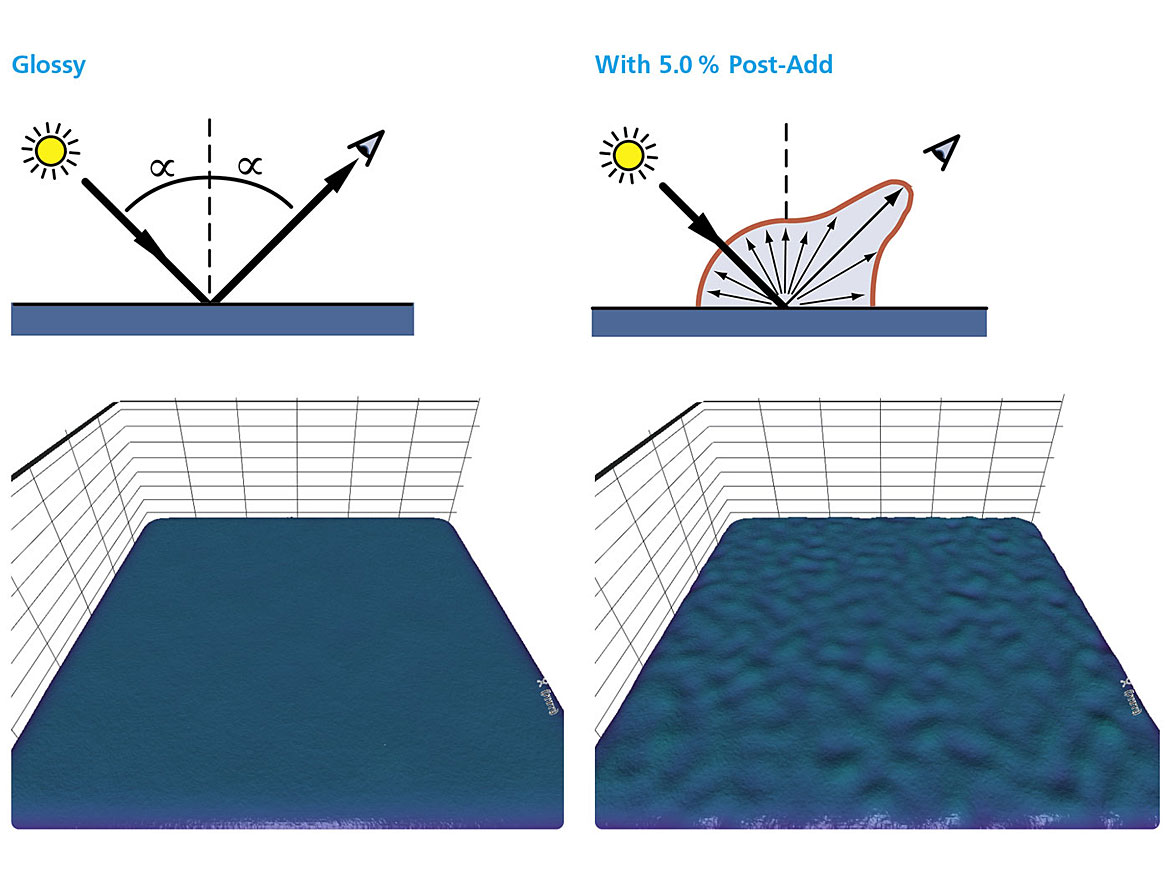

Glossy surfaces reflect the light that falls on them in a targeted, almost parallel direction. This gives high reflection values, i.e. a high gloss.

As soon as light is diffused rather than reflected in a targeted manner, the surface appears matte. The surface must have a very fine texture to create the visual appearance of uniform matting. With a coarse surface structure, the eye may still perceive glossy areas and a sparkle effect may occur.

In Figure 4, the lower pictures show the surface profile of a glossy powder coating in comparison to a powder coating matted with 5.0% BYK-3938 P. This illustration of 3D topography was measured and calculated with spectro2profiler from BYK-Gardner GmbH. The measuring instrument takes several images illuminated from different angles and uses these to calculate the 3D topography. It is cleary visible that there is a microtexture present on the matted surface.

What is the Matting Effect of the Additive Based On?

The additive causes a microtexture on the surface of the powder coating during the coalescence phase. First, the melt viscosity of the binder is increased. The wetting process of liquids (or melts) on solid additive particles requires energy. This is the case when differences in surface tension during wetting process have to be compensated and when the melt penetrates into the pores (capillaries) of the agglomerates.

This wetting process will not be completed because the continuing crosslinking reaction reduces the ability of the melted powder coating to flow. The additive particles are bound in the surface but do not sink completely into the lower layers. Particles near to the surface cause a microtexture in powder coatings. Some particles also protrude from the surface and increase the effect of the diffuse light scattering.

This effect at the surface is comparable to the formation of a fine texture by coarse filler particles in conventional liquid coatings. There, the shrinking layer thickness causes a microtexture around the filler particles once the solvent or water has evaporated.

In powder coatings with BYK-3938 P, the resulting microtexture is “fixed” by the crosslinking reaction and subsequent increase in viscosity. It can no longer flow smoothly. The additive therefore has no direct effect on the chemical crosslinking, but its physical effect is to cause a light-scattering diffusing surface.

For this reason, the effect is constant regardless of reactivity level or curing temperature. This allows the user to quickly implement the desired level of matting. No adjustments are needed to the oven temperature or to dwell times. The curing parameters specified for the specific powder coating remain unchanged.

Application Examples

Which Powder Coating Systems is This Additive Suitable For?

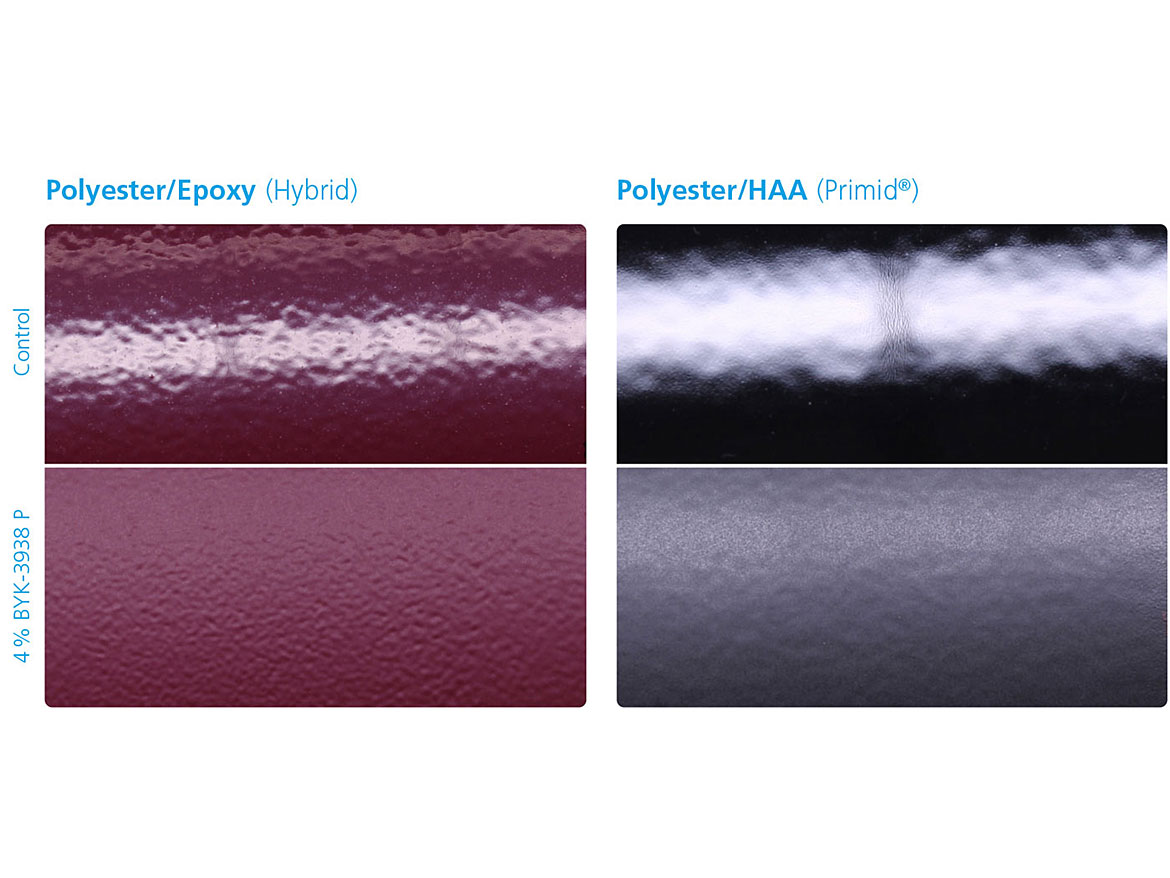

Gloss reduction can be achieved in all binder systems and with all formulations. Since the effect is purely physical, the difference in crosslinking reactions is not important. Powder coatings form a duroplastic network by chemical reaction. All binders are therefore initially thermoplastic and melt in the curing process. In this phase, the additive creates a microtexture that reduces the gloss (Figure 5).

The following binder systems are mainly used in the market:

- Polyester resins

- Epoxy resins

- Acrylic resins

Various curing agents offer a variety of combinations in order to meet the demands of all applications. Polyester resins containing carboxyl groups, crosslinked with β-HAA (β-Hydroxylalkylamide) or TGIC (triglycidylisocyanurate) are used for weather-resistant powder coatings.

Polyester resins containing hydroxyl groups with isocyanate crosslinkers have numerous applications in outdoor resistant systems. Pure epoxy resins and hybrid systems (polyester/epoxy) are primarily used for indoor applications.

Can the Additive Be Used with Clearcoats?

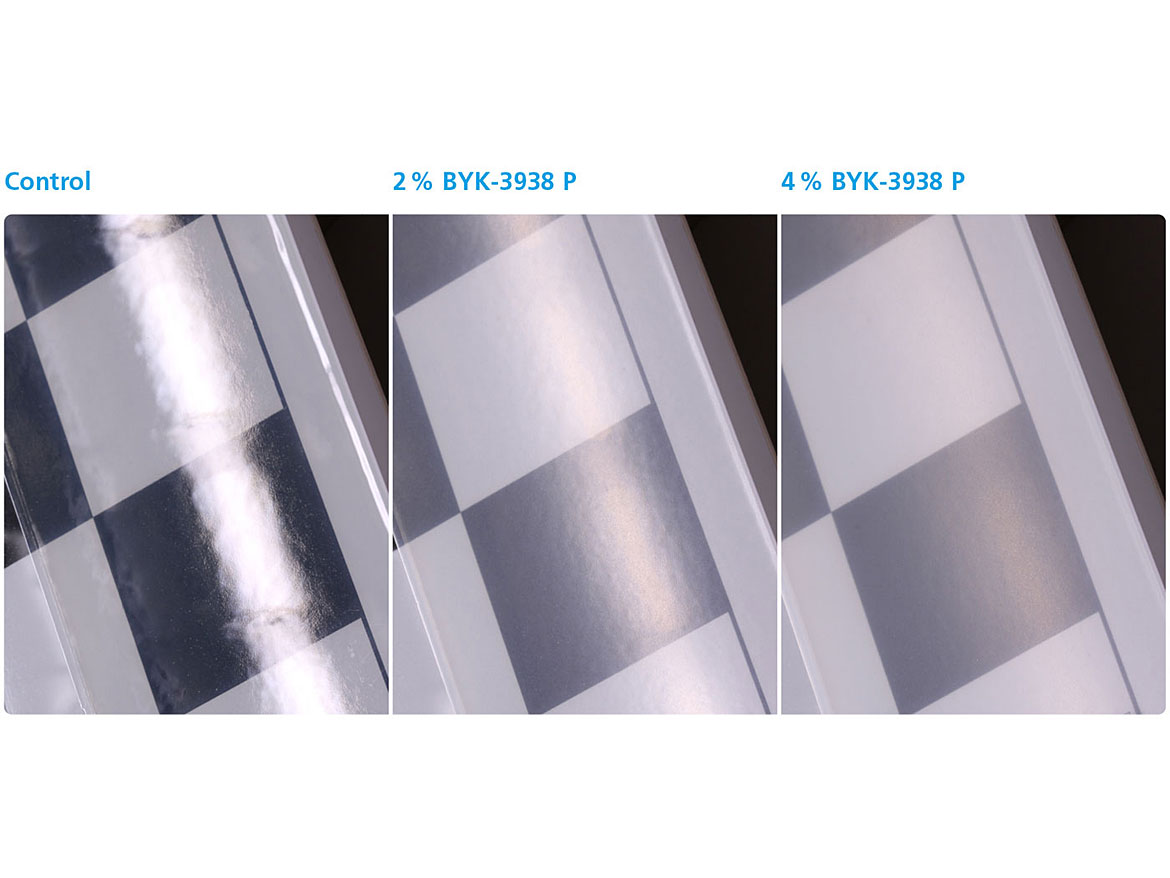

The primary particles provide a high level of transparency due to the chemical composition as a modified phyllosilicate. For this reason, clearcoats can be matted very well with the additive. The microtexture on the surface causes diffuse light reflection. The high intrinsic transparency of the additive particles does not affect the visual properties of the coating. Particles that are not fully wetted with the binder will also cause scattered light reflection in a diffuse manner. As a result, a very uniform and consistent gloss reduction can be achieved in clearcoats (Figure 6).

Does the Additive Work in Effect Powder Coatings?

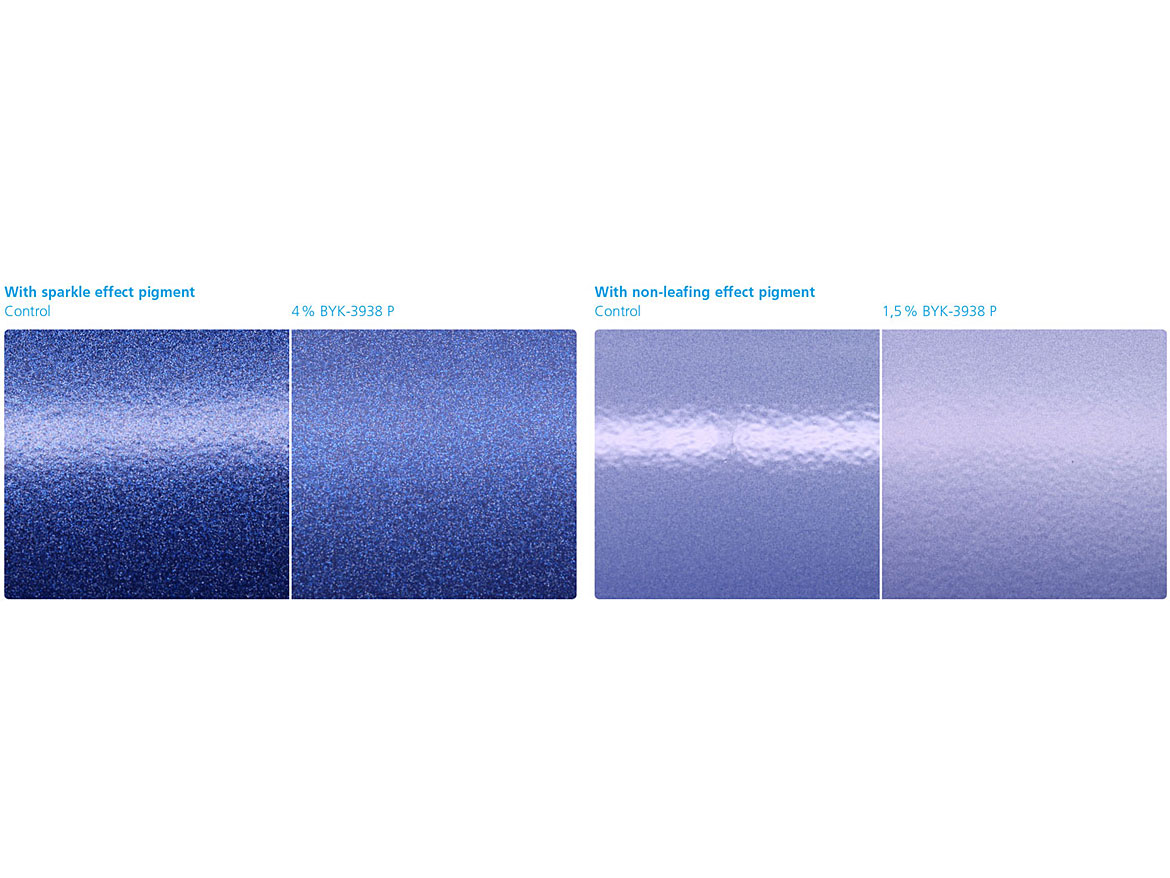

Just as in solid color powder coatings and clearcoats, the additive can be used in effect powder coatings to adjust the gloss value as required (Figure 7).

Neither the visual properties nor the durability of the effect pigments changes by its addition. A uniform matting is achieved in all systems. The platelet-shaped pigment particles remain visible without any distortion to their characteristics. All types of effect pigments are suitable. For aluminum pigments, leafing types or non-leafing types can be used with no difficulty. The novel additive achieves equal gloss reduction in both cases. When taking gloss measurements on metallic and effect coatings, it should be noted that the gloss values obtained do not align with the visual appearance of the gloss.

Can Textured Powder Coatings be Matted with the Additive?

For structured powder coatings, the user first needs to determine whether the structure appearance is fine or coarse. Powder coatings with a coarse structure are very sensitive to contaminants due to the required formulation. Contamination with another powder coating quickly results in visible defects in the form of spots, particles or craters. Disturbance of the structure may occur, causing it to flatten. For this reason, use of the additive in these powder coatings is limited. As can be seen in Figure 8, a gloss reduction is achieved. However, the coarse structure becomes increasingly flat and less clearly defined. A decision must be made whether the resulting structure is within a tolerable range. A series of tests using different dosages is recommended.

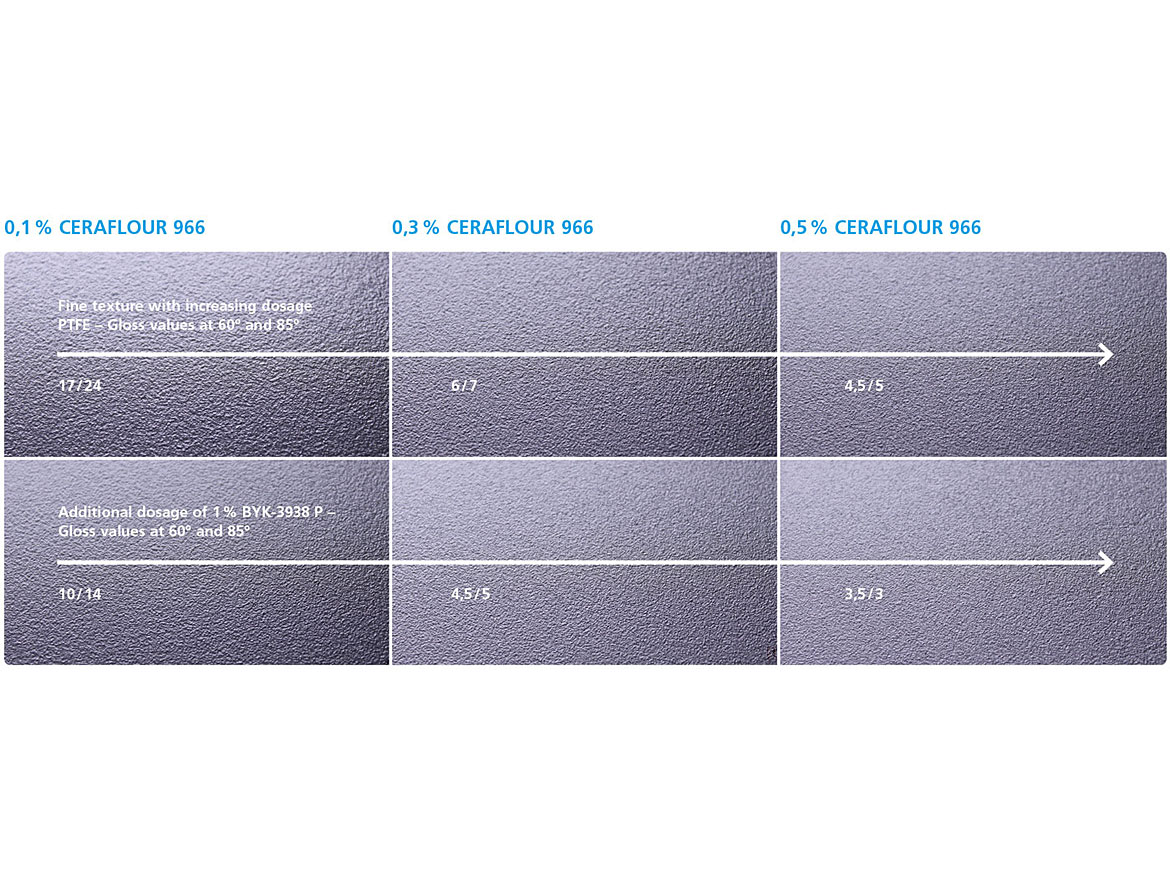

Powder coatings with a fine texture, by contrast, can be combined very well with this additive. Fine textures are generally created with additives based on micronized PTFE (polytetrafluorethylene). The PTFE is either used on its own or in combination with polyethylene (PE). These formulations are very robust and not susceptible to changes in the characteristics of surface texture, whereby the post-addition additive can be described as non-critical.

Fine textures already have a certain degree of matting. For example, the additive can be used in these formulations to make fine adjustments to the gloss value if quality control determines too high gloss values.

As can be seen in Figure 9, there is only a minimal effect on the optical appearance of the fine texture. This is important in terms of reproducing such formulations since deviations in visual appearance are not accepted and can therefore lead to rejection. Corrective measures using the novel additive can adjust the gloss value without affecting the texture itself. The gloss measurement values are given at measurement geometries of 60° and 85°. They each show a reduced level of gloss.

Bottom row, each with an additional dosage of 1.0% BYK-3938 P.

Conclusion

Virtually no changes can be made to powder coatings after they have been manufactured. Where the color shades or other visual properties do not meet the requirements or the specification, corrective measures are virtually impossible. In these cases, the whole formulation has to be reworked and an entirely new batch has to be manufactured.

The novel BYK-3938 P allows effective gloss value reduction even in finished powder coatings using the post-addition process. This process step can be carried out easily with various types of mixing equipment and is therefore significantly more economical than conventional production. Particularly failed batches can be corrected or alternatively used as matted systems.

For the powder coating manufacturer, the benefits of the post-addition process are to create individual gloss values quickly from just one basecoat. Basecoats that have been mixed with the additive can be stored under standard conditions.

Powder coating applicators now have new options available. They can respond to customer requirements immediately before beginning the coating process. Universal use of this novel additive across all binder systems and formulations makes handling convenient for the coater and allows the gloss value to be adjusted to requirements at short notice. Only the common color shades need to be kept in stock as basecoats. This means long delivery times and delays in order processing can be avoided.

Regulatory constraints and safety requirements have been increasing for years. These affect the powder coating industry in selecting raw materials. A variety of labeling requirements apply when processing coating materials and during transportation of coated goods. The label-fee composition of the additive, along with the purely physical working mechanism without effect on chemical reactivity can be outlined as strong benefit. The additive can be used in the powder coating industry without taking any additional measures.

For more information, e-mail Thomas.Czeczatka@altana.com, Judith.Ewald@altana.com or Roland.Albert@altana.com.

Image credits and sources:

Figures 1, 3, 5, 6, 7, 8, 9: BYK-Chemie GmbH, internal images application and research laboratory and product presentation on BYK-3938 P

Figure 2: BYK-Chemie GmbH, FACT SHEET H-XS 20, BYK-3938 P

Figure 4: upper half, BYK-Gardner GmbH, lower half, surface measurement with SPECTRO2PROFILER, BYK-Gardner GmbH

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!