Preservation of Historical Structures with Migrating Corrosion Inhibitor Technology

Images courtesy of Cortec

images courtesy of Cortec

images courtesy of Cortec

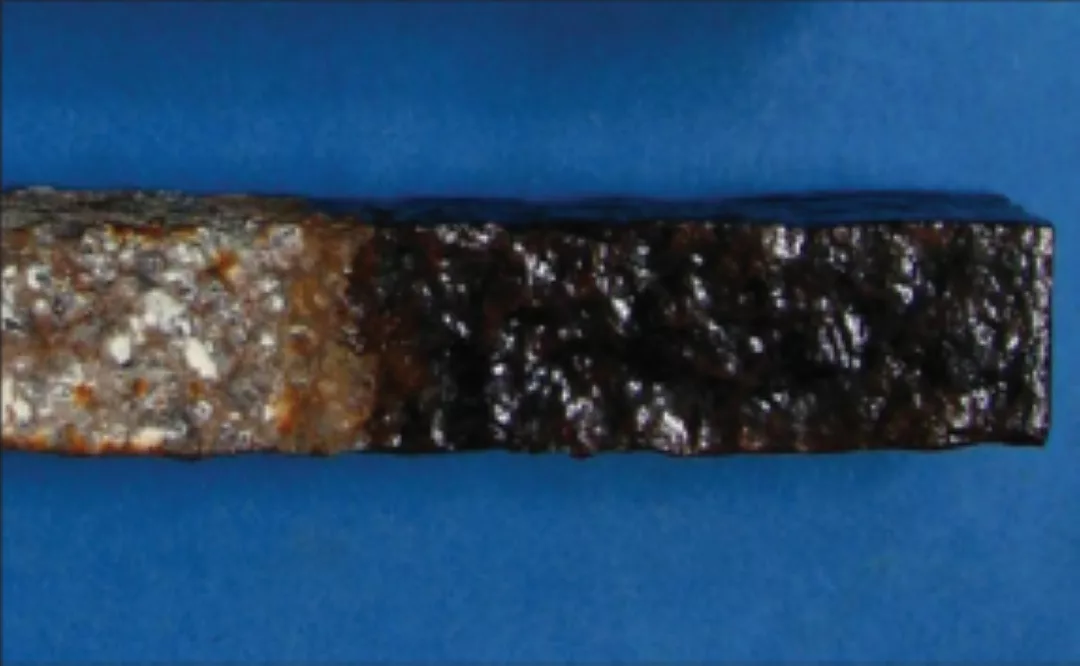

Cortex MCI Rust Primer is applied to the right side of the joint; the coating has converted the corrosion into a protective layer.

Damaged joints.

Damaged joints.

images courtesy of Cortec

images courtesy of Cortec

images courtesy of Cortec

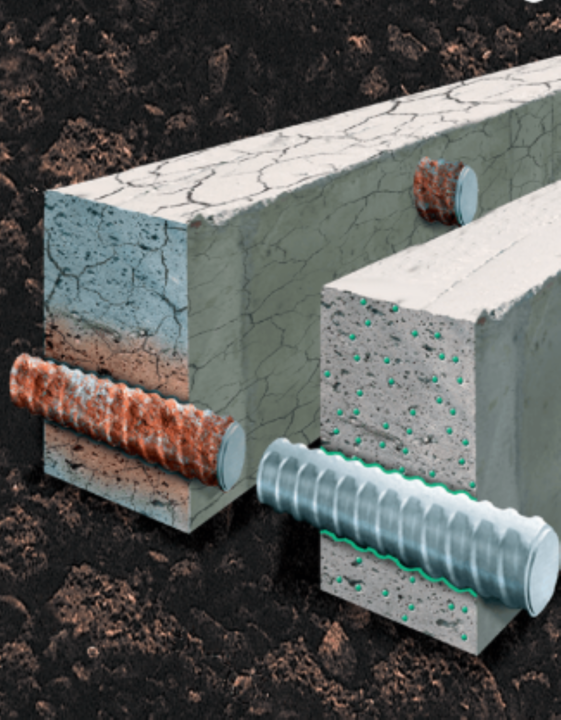

Reinforcement of the foundation of medieval city walls with MCI technology

images courtesy of Cortec

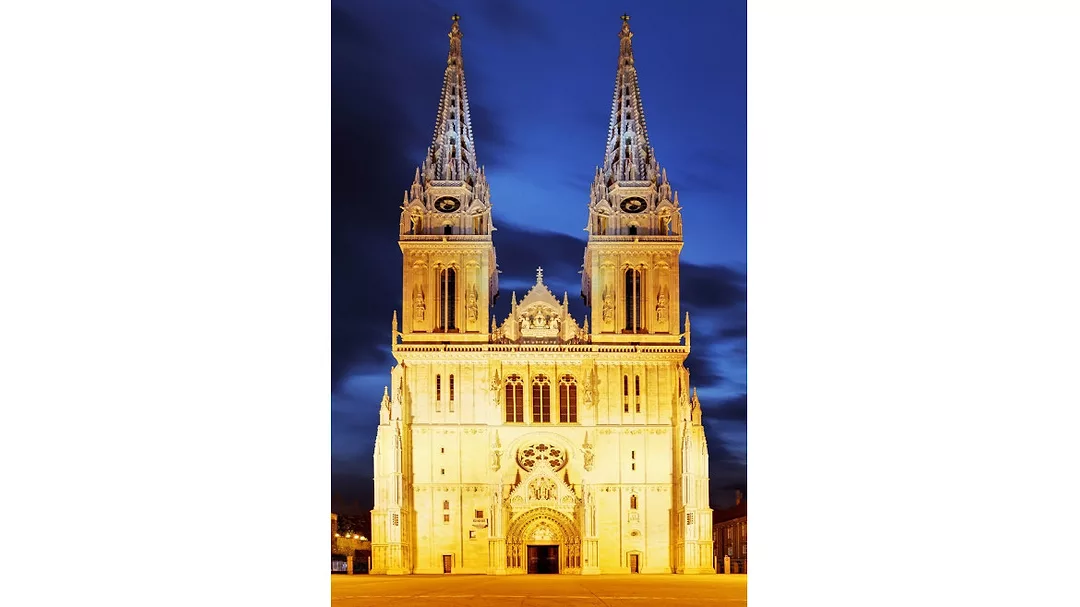

The famous Zagreb Cathedral is the tallest and one of the most beautiful buildings in Croatia and attracts thousands of tourists worldwide. As the most impressive gothic-style sacral building southeast of the Alps, it is characterized by great architectural and historical value. Its construction dates back to 1093, with continued enrichment of the cathedral by famous architects during the following centuries.

Reconstruction of the cathedral in the late 1800s was led by Hermann Bollé, who brought the cathedral to its most recent architectural form in which it stood until the earthquake of March 22, 2020 when the cathedral’s southern spire was damaged. Over the last 30 years, extensive restoration work has been undertaken on the cathedral, with ongoing repairs to this day. During reconstruction work on the south tower of the cathedral in 2012, damaged steel joints were found surrounding the tower 4 inches below the surface at approximately every 1.1 yards between the first and 25th rows. Most of the joints were only partially exposed in order to replace the surface layer of stone on the belltower, while the back of the joints remained embedded in stone and lime mortar. The joints were covered with a layer of rust and, in drainage areas, corroded all the way through the cross-section. In order to define the optimal solution for maintaining or improving the mechanical resistance and structural stability of the tower, the faculty of mechanical engineering and naval architecture of Zagreb was called in to examine the joints.

At their laboratory, they performed experiments on steel joints removed from the cathedral. They recommended doing the following:

- Remove corrosion from accessible joint connections.

- Apply corrosion protection to accessible joint connections.

- Strengthen the joint connections where damage had occurred.

It was suggested that a minimal range of intrusion be used to keep the mechanical resistance and stability of the tower structure at their existing level while keeping costs at a minimum. Cortec’s CorrVerter® MCI® Rust Primer was recommended for corrosion protection. CorrVerter is a water-based product that quickly converts rust into a protective layer and is capable of penetrating into corroded surfaces. It contains a novel chemical chelating agent that modifies surface rust into a hydrophobic-passive layer. A metal brush was used to remove loose rust from the joints. Then, two layers of CorrVerter MCI Rust Primer coating were applied directly onto the metal. A brush was used for the application on smaller metal joint surfaces, while spray application was used for larger areas. The first coat was applied at a thickness of 4 mils. A second coat was applied at a thickness of 3 mil. During application, the coating temperature was 55 °F. The joints were then reinforced with steel fishplates that were welded onto the joints and also protected with the rust primer. The final step was to replace the stones around the joints. With the help of a skilled team and good project management, the entire project was completed successfully with minimal cost and intrusion as specified. The coating penetrated into the metal and stopped further advancement of the corrosion process.

Renovation of Medieval City Walls

The town of Ilok, Croatia, is a place of rich history and cultural heritage. The medieval long fortress and royal castle of Ilok are protected historical and cultural treasures of the highest degree, enabling visitors to step into ages long past. The tower walls have a square floor plan and rest on foundations made of broken stone. These walls are exposed to damaging atmospheric influences, and the binding material between the bricks has washed away, leading to brick deterioration. Renovation work on “tower three” includes strengthening of the foundations, restoration of collapsed parts, and injection of cracks.

The project involves the use of corrosion inhibitors to prolong the life of the structure. Cortec’s corrosion inhibitor, MCI®-2005 is added into concrete being used to reinforce the foundation. This amine-carboxylate-based corrosion-inhibitor additive will be used to protect embedded metallic reinforcement from corrosion in order to extend the lifetime of the walls. MCI-2005 is a water-based, organic corrosion-inhibiting admixture with set-retarding effects. When incorporated into concrete, it migrates towards reinforcement to form a molecular layer that inhibits the corrosion reaction on both anodic and cathodic components of the corrosion cell. In new construction, this protection is quantified by subsequent reduction in corrosion rates when corrosion does initiate. When used with repair mortars and grouts, MCI-2005 not only protects rebar within the patch, but can also help protect embedded reinforcement already in place in undisturbed concrete adjacent to the repair.

You can learn more about Migrating Corrosion Inhibitors (MCI) at https://www.cortecmci.com/.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!