Perfecting Paint Production

courtesy of Wilden

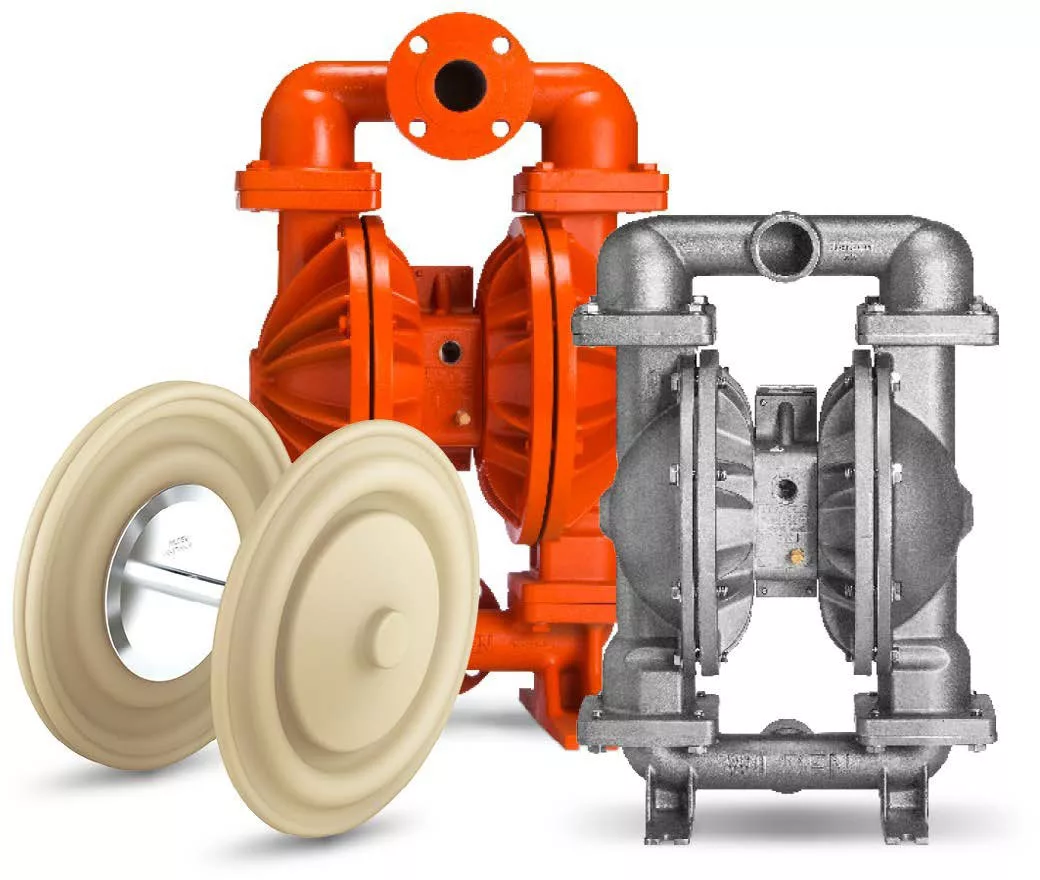

Chem-Fuse IPDs are constructed of Wil-Flex, which enables Wilden AODD Pumps to produce safe, clean, leak-free and efficient product transfer, even when handling the many abrasive liquids that are a staple of paint and coating production.

After seeing how WildenChem-Fuse IPDs can improve service life and pump performance, Dunn-Edwards will begin standardizing the use of Chem-Fuse diaphragms on all of the 3-inch Wilden AODD Pump models in use at its Phoenix, Arizona manufacturing plant.

A house needs many things: floors, windows, doors, appliances, furniture, decor, and a strong foundation with walls that provide the people inside with security and warmth. However, a house only becomes a home once the people living inside have chosen the perfect paint colors. Since 1925, Dunn-Edwards, manufacturer of architectural paints and coatings, has provided paint colors for every part of the home.

The Dunn-Edwards facility in Phoenix, Arizona, continues that legacy. The state-of-the-art, eco-efficient production and distribution facility manufactures more than 15 million gallons of paint annually. By transporting and mixing in excess of 150 unique ingredients, including resins and additives, the Dunn-Edwards facility upholds its high industry standards for reliable and environmentally conscious paint formulation and production.

The Problem with Paint Production

Producing these high-quality paints and coatings requires efficient and safe equipment that can handle abrasive fluids in a shear-sensitive manner. To ensure the safety of plant personnel and the efficiency of the operation, these critical applications require pumping technology that is leak-free and reliable. This is especially true when latex, a complex emulsion consisting of polymer microparticles contained in an aqueous medium, is involved.

Latex is created by a process called “emulsion polymerization,” where droplets of simple emulsion are added to water. Additives are injected into the latex to provide important characteristics, such as color, reflectivity, and anti-bacterial qualities. Many of these additives, such as titanium dioxide (TiO2), are extremely abrasive and cause elastomer wear that leads to regular and extensive pump maintenance, increasing downtime and affecting operational performance.

For the Dunn-Edwards facility, the pump of choice for ensuring its production operations meet the company’s reliability and environmental-sensibility requirements are air-operated double- diaphragm (AODD) pumps from Wilden®, a brand of PSG®. Wilden AODD pumps have been proven to excel when handling paint components, thanks to a unique design that offers the highest degree of flexibility and performance in terms of reliability, product-loss prevention, environmental protection, and energy efficiency. In addition, Wilden AODD pumps are easy to maintain, self-priming, dry-run capable, and deliver a shear-sensitive operation that is mandatory when working with these components.

In August 2020, Phoenix Pumps, a long-time distributor for Wilden, offered Dunn-Edwards an opportunity to explore operational cost savings by assessing alternative AODD pump-diaphragm options. Dunn-Edwards was using Wilden’s EZ-install diaphragms, which offer great benefits in terms of chemical compatibility as well as safe and easy installation. However, due to the aggressive nature of latex, these diaphragms were still being replaced every six to eight months.

With nearly 200 AODD pumps, divided between 1-inch, 2-inch, and 3-inch (25-76 mm) variants, Bill Murphy, technical field specialist for Phoenix Pumps, knew Wilden had an alternative to increase the mean time between repair (MTBR) for Dunn-Edwards’ operations.

Introducing Chem-Fuse

Murphy’s relationship with Steve Chapin, the maintenance manager of Dunn-Edwards Paint’s Arizona facility, and collaboration with Rob Jack, the regional sales manager for Wilden, allowed them to assess the installation and recommend Wilden’s Chem-Fuse Integral Piston Diaphragms (IPDs). As a performance comparison, Chapin outfitted a few 3-inch pumps with Chem-Fuse IPDs and corresponding shafts and inner pistons

The one-piece, zero-adhesive design of the Chem-Fuse IPD perfectly complements the high demand of the facility’s AODD pumps because they have been engineered to hold up against acids, caustics, and other aggressive fluids, such as latex. Chem-Fuse diaphragms feature a one-piece design that eliminates the need for an outer piston that is a common leak point in traditional pie-shaped diaphragms, which create a trap area for product buildup that can wear over time, especially when pumping abrasive fluids. Chem-Fuse offers safe, clean, and reliable product transfer with no product entrapment areas to minimize product contamination, risk liabilities, and ultimately decrease diaphragm life. Available in Wil-Flex material in 1-inch (25 mm), 1-1/2-inch (38 mm), 2-inch (51 mm) and 3-inch (76 mm) sizes, Chem- Fuse also offers up to 100% increased flow and suction lift compared to other reduced-stroke IPDs. It also is easy to install and easy to clean for faster changeovers.

The test pumps outfitted with these diaphragms exceeded one year of operation (eight hours per day, five days per week). Operating relatively trouble-free, the pumps equipped with Chem-Fuse have improved Dunn-Edwards’ operation by increasing the service life of the pumps, requiring fewer service hours, minimal maintenance downtime and costly draining cycles. “The two main takeaways from having seen them in operation is that they are lasting longer and the reduction in mating surfaces makes them easier to rebuild and naturally more resilient as a result,” Chapin said. He continued, “There are basically three parts to assemble versus the old setup, which was seven.”

Conclusion

With the elimination of potential leak areas, extended flex life, and easy cleanability for efficient product changing, the Chem- Fuse design was ideal for the aggressive latex-handling applications inside the Dunn-Edwards facility.

Because of the success of the AODD pumps outfitted with these diaphragms, the Dunn-Edwards facility will install Chem-Fuse diaphragms into every 3-inch pump it uses for latex-handling applications, ensuring a pump fleet with an operational life measured in years instead of months. Doing so will allow the Dunn-Edwards facility to continue upholding its reputation of providing an array of high-quality paints and coatings in a safe and eco-friendly manner.

* Photos courtesy of Wilden

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!