Considerations When Choosing Pneumatic vs. Electric Industrial Mixing Equipment

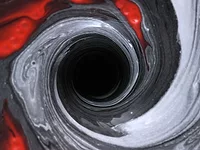

Credit: AVAKAphoto, iStock / Getty Images Plus, via Getty Images.

Electrically and pneumatically powered industrial mixers are both common mixer types found in paint and coatings production facilities. But, depending on the specific application, one may be a more suitable solution than the other. This article discusses some of the top considerations to keep in mind when making an investment in new mixing equipment.

Power Source Requirements

The first step is to understand the specific details for each available utility. For electrical power, this includes the voltage, phase, and verification that the circuit amperage capacity is sufficient. The most common electric power sources are 120/230V, single phase from standard wall outlets and a variety of higher voltages utilizing three-phase power such as 230/460V. Three-phase power is most common in industrial and commercial locations. Pneumatic power systems are driven by compressors delivering airflow via sealed pipe networks. In these cases, the compressor output (volumetric flow rate and pressure expressed as “x GPM @ y PSI”) should be determined. Additionally, long piping runs or simultaneous use of the system to drive additional equipment reduces available power for the mixer at the point of use. Before selecting an air-powered industrial mixer it is important to verify that the compressed air system can drive the subject pneumatic mixer motor, as air motors require significant volumetric flow delivered at high pressure. Consult the air motor’s manual and performance curve to verify that the compressor output is capable of powering the mixer.

Cost Differences

For portable mixers such as clamp mount mixers or 55-gallon drum mixers, the cost to acquire an air-driven or single-speed electric mixer is fairly comparable for mixing in containers from laboratory sizes up to 250 gallons. Operating costs of pneumatic motors for batch sizes much larger than this becomes less feasible as air volume requirements and electricity cost for the compressor increase dramatically.

Since pneumatic mixers are simply controlled by an air valve, variable speed is essentially an included feature. Variable speed control for electric mixers, on the other hand, requires the addition of a DC motor control or a variable frequency drive (VFD), which is an additional cost. When speed control is necessary for an application, electric mixers are more expensive than a similar powered pneumatic version.

Operational Differences

The torque vs. speed profile of a mixer can be very important depending on the application. For example, single-speed, direct-drive electric mixers are ideally suited for light liquids or lower-viscosity formulations, but as liquid density or viscosity is increased, so is the need for higher torque.

This is important because using an under-powered electric direct-drive mixer will result in the motor overheating and eventual equipment failure. Pneumatic direct-drive mixers have an advantage in this regard because overloading will only result in a stall, and not a total motor failure. However, pneumatic motors do not reach a consistent torque output until they are turning several hundred rpm. This may be a limiting consideration if running a product at very low shaft rpm is desired. Whether powered by electricity or air, the ability to run at lower speeds with higher torque is achieved by using a gear reducer in the mixer design. For example, a shear-sensitive specialty paint or coating with high solids content is an ideal candidate for low-speed mixing by either an electric or pneumatic mixer with a gear reducer and very gentle mixing impeller such as a three-blade hydrofoil. A direct-drive electric mixer with speed control may also be an option with the hydrofoil, depending upon the properties of the formulation. However, direct-drive with a pneumatic mixer may struggle to provide consistent low-speed mixing due to fluctuating torque over that portion of the air motor’s operating range.

To push higher viscosity liquids such as heavy primers, varnishes or other similar formulations, gear-driven mixers must feature larger shaft diameters and larger mixing impellers than direct drive models. DC motors are paired with DC motor controls for variable-speed electric mixers as these motors provide greater torque output versus AC motors. The motor controls rectify the AC current provided by a standard 120V outlet for fractional horsepower motors commonly used with portable mixers.

Safety and Environmental Factors

Environmental and safety considerations are a frequent reason or large factor in the purchase of mixing equipment. For hazardous environments due to combustible ingredients, environmental gases, vapors or dust, pneumatic mixers are often selected since they are considered inherently safe because they do not present an ignition source via a spark. In these environments the acquisition cost of a mixer is much lower than electric versions that are also designed for hazardous environments.

Explosion-proof electric motors are higher priced, heavier, and require installation by a certified electrician when used in hazardous environments. If variable speed is desired then the controls are required to be placed outside of the hazardous environment, further adding to the cost and complexity of the mixing setup. While explosion-proof motor controls, or VFDs, are available they are also very expensive.

Another environmental factor to consider is the noise created by mixing operations. Pneumatic motors are generally considered loud, especially when equipped with standard mufflers at the motor exhaust. High-performance mufflers are available and can make a significant sound difference, but air-powered industrial mixers are generally still louder than electric mixers.

Before purchasing a new industrial mixer, it pays to do your homework. Understand your mixing requirements, setup limitations, safety conditions, environmental factors, and budget to pick the right type of industrial mixer for your needs.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!