Measuring Multiple Automotive Paint Layers

May 18, 2023

Measuring Multiple Automotive Paint Layers

May 18, 2023janiecbros, Creatas Video, via Getty Images

Painting an automotive vehicle is a challenging and multistep process. It includes surface preparation, applying four to six layers of paint, and making sure each layer is the optimal thickness. If one of the layers is not sprayed correctly, it affects the finish of the car both aesthetically and functionally when exposed to the elements.

A complete paint job on a car usually has four to six layers of paint. These layers include electroplating, a primer, a base-color coat, and a clear coat, on a metal substrate. Some colors have an additional layer of paint (mica) to act as a wear protectant. The primer is designed to make the surface uniform so the paint color can be applied evenly. The base color is the actual car color, and the clear coat is an optically clear layer designed to protect the base color from environmental damages such as UV-degradation and oxidation.

The thickness of the paint layers is usually measured in mils or microns, and each car can have between 60 and 120 inspection points. The number of layers and inspection points varies depending on the make and model. Many current techniques only provide the total thickness of the paint and not the individual layer measurement. After each layer of paint is sprayed and cured, the inspector takes thickness measurements at pre-defined inspection points to measure the total paint layers, then manually calculates the thickness of the applied layer. Layer thickness is usually measured in the same spots to monitor trends over time.

Measuring the Thickness of Automotive Paint at the End of the Production Line

Overall, this process is tedious and requires many manual operations. Fortunately, there is a faster solution. Some leading-edge, ultrasonic thickness gauges can provide both the thickness measurement of each individual layer, and the total thickness measurement of several layers at once. This method makes it possible to measure the thickness of the paint at the end of the production line after the application of all coats, instead of doing so after each coat.

The individual layer thickness is crucial for the manufacturer and for car service providers, such as auto body shops, to correct any paint defect. This measurement gives them a rough estimate of how much paint to remove in order to prepare the surface for re-spray so that the finish is consistent with the manufacturer’s specifications.

Faster and Easier Measurements of Automotive Paint Layers

The 72DL PLUS™ ultrasonic thickness gauge is an ideal instrument for determining automotive paint thickness as it provides high-speed and high-frequency measurements of up to six layers. It also provides the individual layer measurements and total thickness measurements with one test.

Its intuitive software makes paint thickness tests easier and faster. For routine inspections, you can save a recall setup. Simply recall the setup from the gauge in order to start an inspection in just a few seconds. The exact setup can be shared with multiple instruments for consistent inspection processes and easy comparison of data from multiple locations. These setups can be easily exported and imported in CSV format on a USB drive and emailed to another location. The instrument supports inches, mils, millimeters, and microns for thickness measurements.

The M2104 (125 MHz) transducer is recommended for automotive paint thickness tests using the 72DL PLUS gauge as it has a high enough frequency to measure multiple ultrathin layers. It also has three plastic discs that allow the transducer to be moved over the inspection part without abrading the painted sample.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

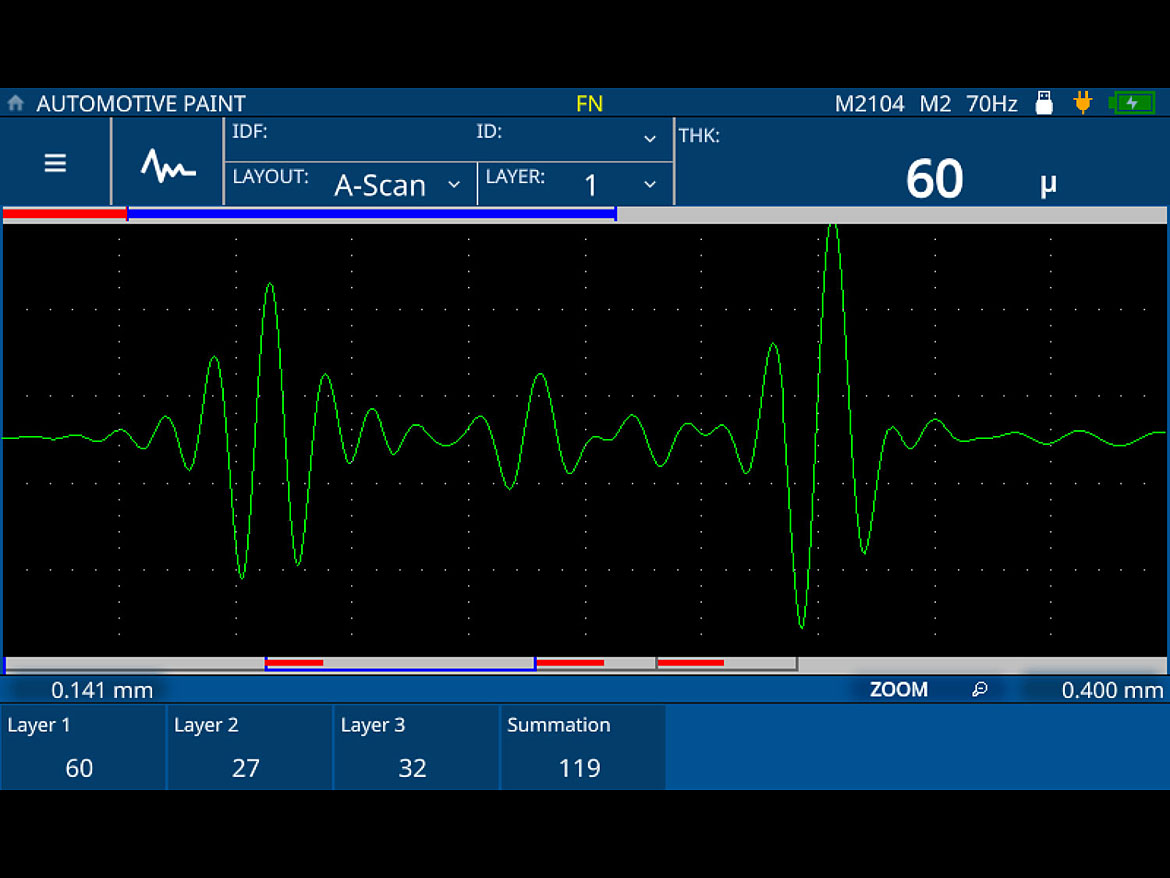

Example of a Multilayer Paint Measurement

Here is an example of a multilayer automotive paint application that has a clear coat, pigment, base coat, and primer. Figure 1 shows an image from the 72DL PLUS gauge (high-frequency model). It shows the paint layer thickness of the four individual layers and the total thickness on the live inspection screen.

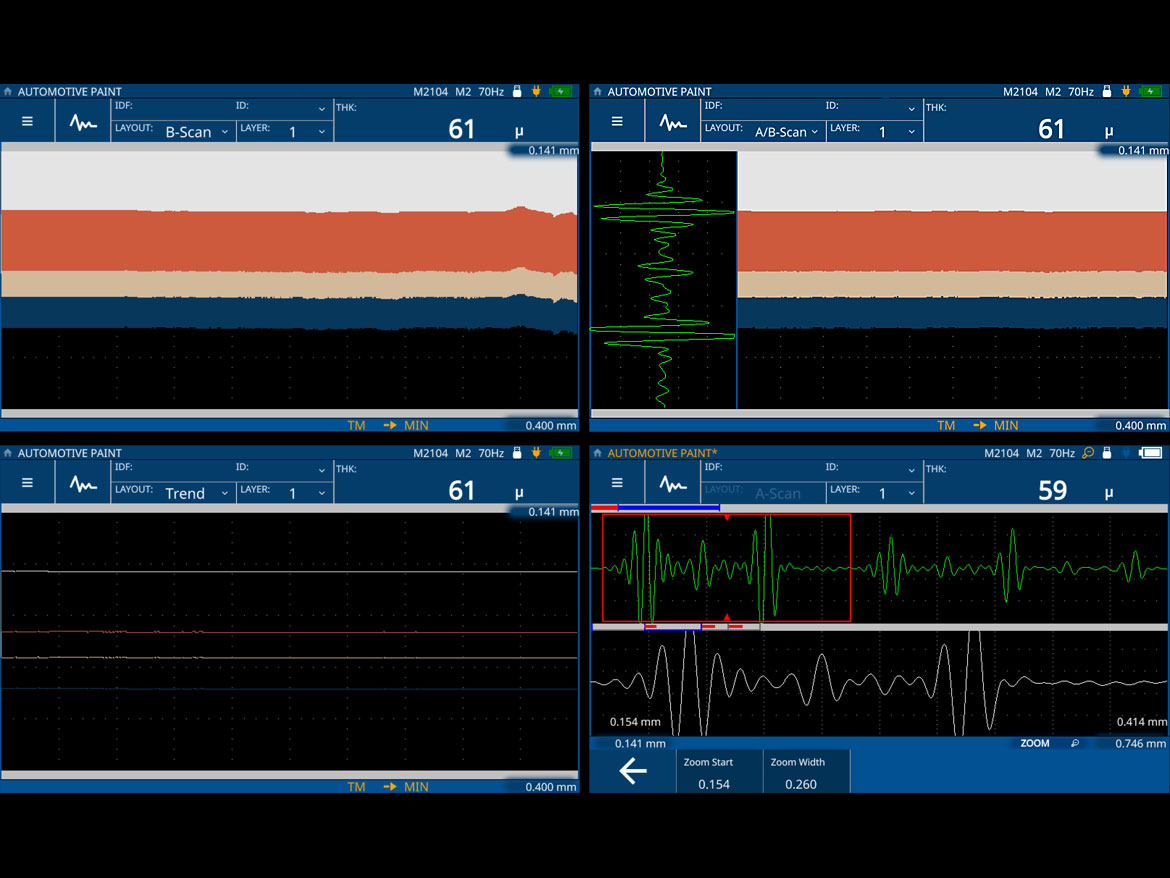

The 72DL PLUS gauge also offers five different layouts for data presentation — A Scan, B Scan, A/B Scan, Trend, and Zoom — to help better understand individual layer thicknesses. The images below in Figure 2 show some of the ways you can visualize paint layer thickness on the gauge using these layouts.

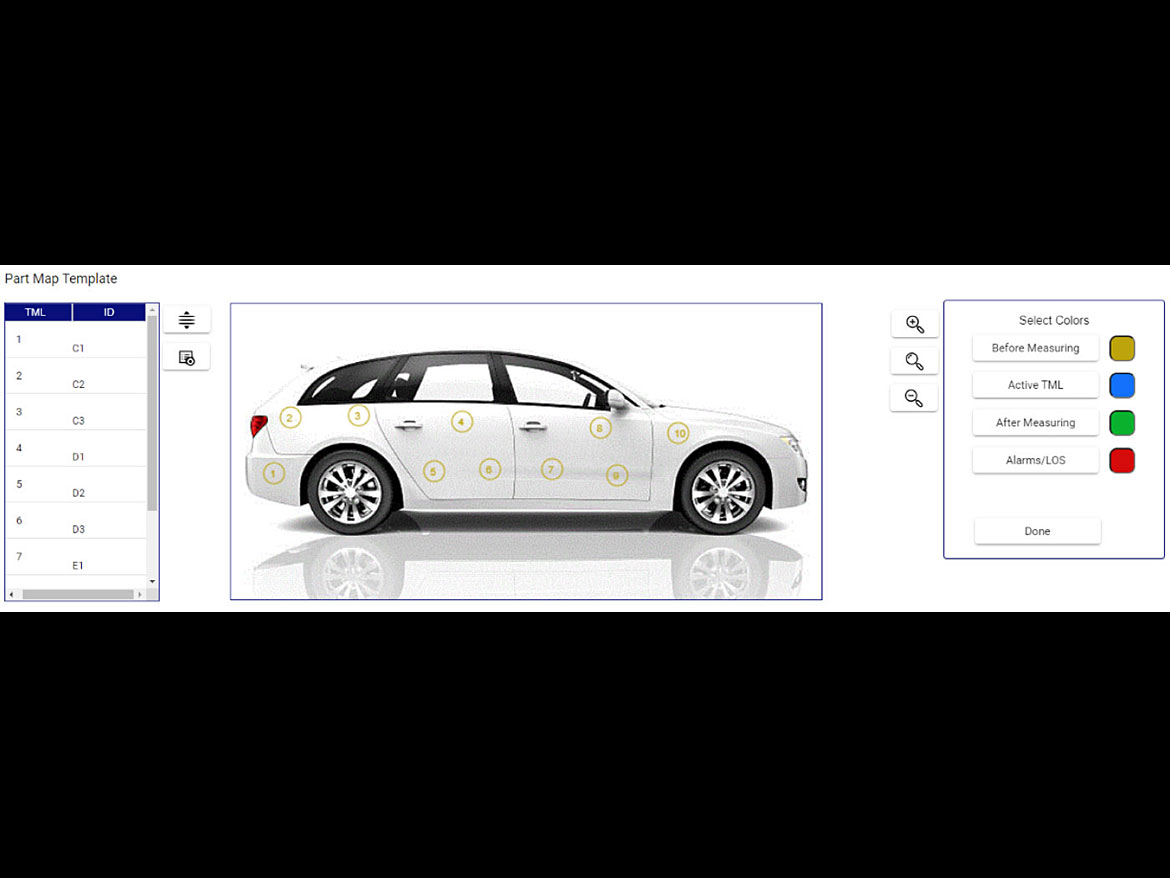

Another helpful feature is the guided inspection with an interactive template view (Figure 3). The interactive template shows an image with the thickness measurement locations. This feature lets the supervisor or the quality team mark the measurement locations on the image and save it for the part setup. Users can customize colors to overlay on the uploaded image to indicate the following stages for the thickness measurement location (TML): before measuring, current, after measuring, and alarms/loss of signal (LOS). The inspector on the production floor just needs to recall the setup with the image and TMLs, then start taking thickness measurements. When a measurement is saved, the color of the TML changes and the instrument moves focus to the next TML. The inspector can also select any TML for the current inspection by tapping on the corresponding TML. This feature provides inspection workflow guidance, as well as a quick visual status of inspection completion and alarm conditions for the part. The inspector can also jump between TMLs with a simple touch to retake measurements in locations without measurements, or with measurements that are outside the expected thickness range or affected by LOS.

The supervisor can also set boundary values for each layer while setting up the part on the gauge. When the inspector measures a value that is outside the expected value for a layer, the instrument will alert the inspector by setting off the alarm on the instrument and displaying the layer thickness in a different font color.

The instrument also has a built-in data logger of 2GB to store approximately 400,000 thickness readings and 20,000 waveforms. This storage space enables the inspector to finish the day’s work without any interruptions. Then they can transfer the inspection data files to the PC-interface application for data analysis and reporting.

These advanced capabilities make the 72DL PLUS gauge a powerful tool for automotive paint applications. With a streamlined process for paint thickness measurement, automotive manufacturers can design a more efficient production floor as they focus on developing the cars of the future.

.webp?height=300&t=1745333386&width=300)