Olive Stone Powders: A Natural, Sustainable Option for the Paint & Coatings Industry

From waste stream to high-performance functional powders

Dudits, iStock / Getty Images Plus, via Getty Images.

All around the world and across industries, businesses are called to be more sustainable, green, and clean. Hence, companies are increasingly required to balance economic, social, and environmental considerations to ensure a better quality of life for current and future generations.

Amidst this push for sustainability, the paint and coatings industry may face some challenges due to the environmental and health impacts of some of the chemicals commonly used in its products. However, the market now provides natural, sustainable options that can even enhance physical and mechanical properties of coating formulations. These alternatives include bio-based binders, biodegradable texturizers, recycled content, and natural pigments.

The Incredibly Useful Olive

A circular raw material that has lately gained wider attention is the olive pit, a byproduct from the olive oil mill. Olive oil manufacturing involves compressing of the whole olive, which produces a solid residue of pulp, peel, and fragmented pits. In the past, raw olive pits have mainly been used for combustion. In some countries, they are still considered waste products and not yet part of any upcycling value chain.

According to the International Olive Council,1 the global olive oil production volume for the 2021/22 crop year is estimated at 3.10 million metric tonnes, up 2.9% from the year before. Hence, there is a massive amount of olive pomace (pulp) left behind, which comes with certain disposal challenges because of its fat and polyphenolic compound content. Fortunately, new technologies have emerged to recover this waste stream and to break it down into its components.

Specialized machines are used to process the pomace in a moist state, and olive pit fragments are separated from pulp and shell through a centrifugation process. The fragments are then mechanically cleaned, dried, and screened based on their particle sizes. Through this complex treatment process, BioPowder recovers light beige granules that are free of any dust/pulp and nearly odorless. The company further processes them into top-grade micronized powders with different surface functionalization options. Marketed under the brand name Olea FP, they are fully circular additives with desirable properties for modern coating formulations.

BioPowder obtains a consistent supply of top-grade olive pits from carefully selected mills and converts them into pure, clean granules, powder, or flour of specific micron-range accuracy.

BioPowder obtains a consistent supply of top-grade olive pits from carefully selected mills and converts them into pure, clean granules, powder, or flour of specific micron-range accuracy.

Technical Benefits of Micronized Performance Powders from Recycled Olive Stones

For paints, floorings, and other coating systems, the olive stone powders present an exceptional range of opportunities thanks to the following mechanical properties:

- High hardness of >3.5 on the Mohs scale: The company’s olive stone functional powders have a high level of hardness, making them suitable for use in coatings that require elevated strength, stability, and abrasion resistance. This results in a long lifespan of functional coatings for outdoor and high-traffic areas.

- Low oil- and water-binding capacity: Due to their low oil- and water-binding capacity, these bio-based alternatives provide particle stability with no risk of swelling or expansion. This feature facilitates incorporation in both water- and solvent-based formulations, improves the durability of coatings and reduces the likelihood of cracking or peeling.

- Low density: The functional fillers are low in density and therefore ideal for use in lightweight materials. This feature can also offer cost-saving potential by reducing the per-kg amount needed for volumetric batches.

- Compact particle shape: The compact particle shape of the olive stone powder allows for high predictability and ease of incorporation in coatings. The effect is generally a good dispersibility, leading to a smooth texture.

- Reactive particle surface: Surface reactivity can either be taken advantage of or suppressed through functionalization. This feature allows for the production of coatings with tailored properties such as improved adhesion or water resistance.

- Thermal resistance and insulating properties: The fillers have thermal resistance and insulating properties. This is particularly relevant for industrial coatings, e.g. for use in pipelines or storage tanks, where thermal resistance and insulation are critical.

Demonstrated Effects in Formulations

Reduction of Gloss

One way in which the olive stone powders can enhance paint and coating formulations is by reducing their gloss. The micronized powders have proven effective as matting agents, among others in the following ways:

- As natural pigments in a PU-acrylate matrix: The fillers were added to a PU-acrylate matrix to modify the color and gloss of the coating. The addition of the powder resulted in a color change towards the red/yellow spectrum and a gradual opacification of the paint. The overall gloss of the paint was reduced to nearly 50%, creating an increasingly matte finish.

- In replacement of polyethylene (PE) matting powders in acrylic paint formulations: A functionalized (hydrophobic) grade of the olive stone powder was added at a concentration of 10%. The comparative study showed a reduced gloss at all incident angles, with the 0-100 μm being most effective particle size range.

On the whole, the conducted studies demonstrate the effectiveness of the bio-based additive as a matting agent in various types of paint formulations, including epoxy and acrylic paints. By reducing the gloss of such coatings, the product can help create a matte finish, which is desirable in many applications such as automotive or furniture coatings. Additionally, their use as replacements of traditional matting agents like PE powder can greatly reduce the environmental impact of coatings manufacturing.

Reinforcement and Enhanced Abrasion Resistance

The high hardness of the olive stone functional powders makes them ideal for use as reinforcing agents in coatings. By adding variable doses, manufacturers can improve the coatings’ resistance to wear and tear, i.e. caused by impact and abrasion. This feature is particularly useful in applications where coatings are subjected to high levels of stress, such as in marine or industrial settings. As part of a comprehensive study, the following tests were conducted:

- Indentation tests: In a PU-acrylate coating reinforced with the olive stone powder particles, it was found that doses of olive stone powder as low as 5% could increase the hardness of a paint by up to 20%.

- Taber tests: The above-mentioned PU-acrylate formulation with varying load percentages of olive stone powder was subjected to rotating Taber wheels. The latter applied pressure on the surface, which gradually removed the coating layer. It was found that the use of olive stone powder reduced mass loss by up to 50% in less than 600 cycles.

BioPowder’s reinforced linoleum ‘naturazzO’ is a resilient flooring solution that contains up to 40% of the olive stone powder composite fillers. It has been proven effective for high-load industrial surfaces.

BioPowder’s reinforced linoleum ‘naturazzO’ is a resilient flooring solution that contains up to 40% of the olive stone powder composite fillers. It has been proven effective for high-load industrial surfaces.

These results demonstrate that olive stone powder improves the abrasion resistance and hardness of formulations. Consequently, these functional fillers can help extend the lifespan of coatings, which ultimately boosts efficiency and supports less frequent use. Additionally, the powder’s feather-light properties make it an attractive option for lightweight coatings in applications where every gram counts.

Natural Particles for Texture and Surface Effects

In addition to its use in matting and reinforcement, these bio-based additives are also an excellent option for creating unique surface textures in coatings. Manufacturers looking for bio-based alternatives can consider using olive stone functional powder for the following uses:

- Functional filler and viscosity agent: Incorporating olive stone powder in epoxy, acrylic, or other formulations allows for viscosity and rheology adjustments while improving the overall strength of the formulation.

- Surface texture particles: Olive stone particles can be scattered on the surface of coatings to create a decorative and/or antislip effect. The texture particles are available in grain size ranges from <50μm up to 4mm, allowing for a large spectrum of texturing options.

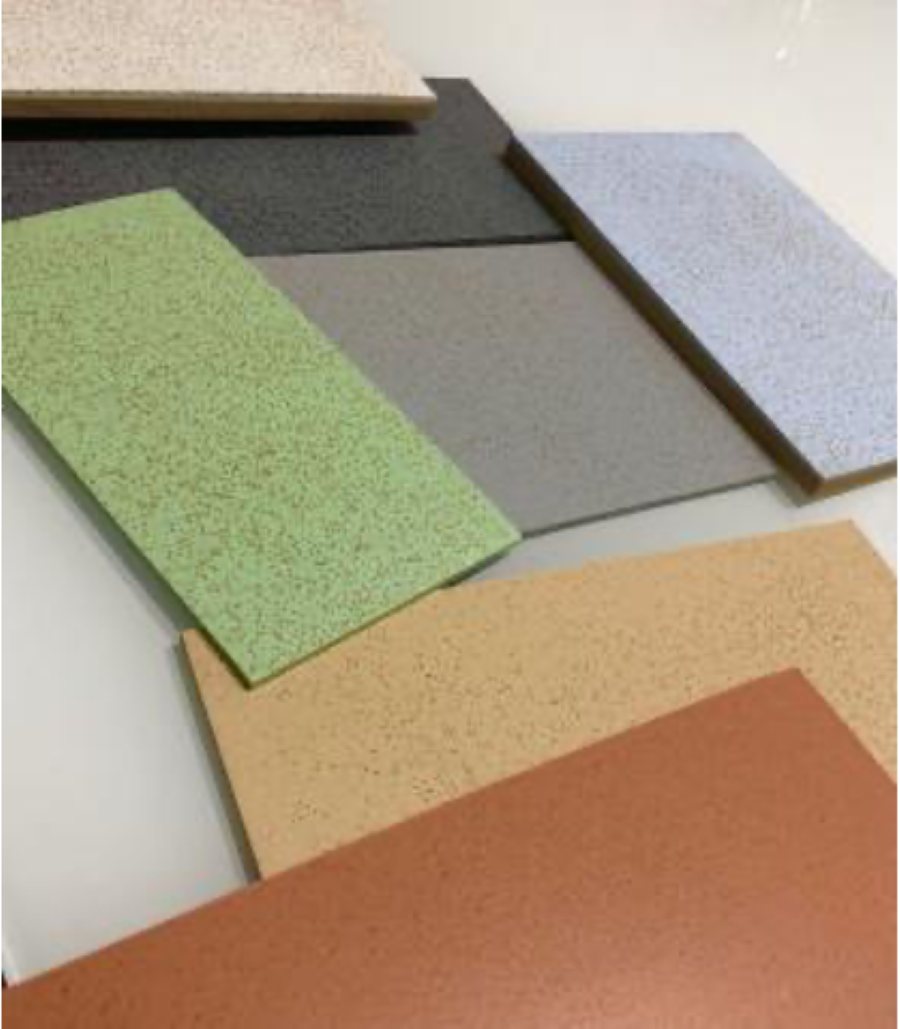

- Decorative particles and pigment carriers: Besides being well suited for decorative effects, the texture particles are powerful pigment carriers. Tests have demonstrated high levels of effectiveness with pigments from both natural and synthetic sources. In response to the high demand for all-natural texture particles, e.g. as alternatives for quartz or polymer particles, BioPowder has recently launched its own color particle range marketed under the brand Olea Colors.

Manufacturers can create unique surface textures with the company’s natural particles. Recommended systems for particle incorporation include epoxy, PU, and poly-aspartic resins.

Manufacturers can create unique surface textures with the company’s natural particles. Recommended systems for particle incorporation include epoxy, PU, and poly-aspartic resins.

In sum, the use of Olea FP in coatings comes with multiple advantages. As a compostable material, it constitutes an eco-friendly alternative to conventional matting particles. Its resistance and lightweight properties make it an attractive reinforcing option, while its customizable micron ranges provide versatile surface texturing opportunities. Manufacturers would ideally take advantage of these effects in combination to create attractive design coatings from renewable sources.

Bio-Based Functional Powders: Green Innovation with an Optimized Carbon Footprint

The need of companies to adopt sustainability throughout their value chain has doubtlessly become imperative. But what does it take to be truly eco-friendly and set new standards for responsible manufacturing practices? Specifically, what makes a coating stand out as more sustainable? The answer lies in the carbon footprint, and hence a full life-cycle assessment, of all materials used in a formulation.

Measuring the CO2 output in all stages of the manufacturing value chain has become a recognized benchmark. In this regard, BioPowder has committed to lean practices that are deeply ingrained in the circular ecosystem of olive by-products. As a consequence, olive stone particles come with an optimized carbon footprint: they are manufactured 100% mechanically, i.e. with electricity being the main required utility. The use of water is minimal, and production does not generate any waste. Most remarkably, olive trees are among the plants that bind the largest amounts of CO2. Evidence shows that roughly 1.5kg of CO2 is produced per liter of extra virgin olive oil. However, an olive orchard can absorb up to 10kg of CO2 while growing the equivalent quantity of olives.2

In conclusion, it can be said that olive stone powders are doubtlessly creating opportunities for carbon-efficient innovation in paint and coatings. The BioPowder team supports coatings manufacturers throughout all stages of R&D and production and looks forward to new project partners.

For more information, visit www.bio-powder.com.

References

1 International Olive Council, The World of Olive Oil, 13 Jan 2022

2 International Olive Council, Application for the Calculation of CO2 Balance in Olive Farming, 27 Jul 2016

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!