New Developments in Vinyl Acetate/Ethylene Emulsions

Improving Block Resistance in VAE-Only Non-Flat Paints

Vinyl-acetate/ethylene (VAE) emulsions are cost-effective and high-performance binders widely used in low-sheen contractor paints. The hydro-plasticizing effect of water enables VAE co-polymers to exhibit significantly lower minimum film-forming temperature (MFFT) compared to acrylics and vinyl acrylics with similar glass-transition temperatures (Tg).1 As a result, VAE-based paints have lower coalescent demand compared to other binder chemistries. This unique property has enabled paint manufacturers to make high-performance, low-VOC, low-odor paints with VAE emulsions.

However, at higher sheens (semi-gloss), the relative softness of VAE is very detrimental to the development of block resistance. Block resistance is a measure of the surface tack of the painted surface and its tendency to stick to each other when contacted. At higher sheens, VAE-based paints tend to stick to each other, resulting in tearing or peeling upon separation.2 Since higher sheen paints are often used to paint window and door trims, high block resistance is critical to maintain film integrity when opening windows and doors. Also, the higher surface tack makes VAE-based higher sheen paints prone to dirt pickup. Typically trim paints are expected to have room temperature block resistance rating above 5, indicating that the paint film has slight surface tack, but does not stick to each other.

Several strategies have been used in the past to increase block resistance of VAE paints:

- Blending with higher Tg acrylics;3

- Raising Tg to make VAE harder;

- Changing the morphology of VAE by introducing small hard hydrophobic domains in the VAE matrix.4

While each of these strategies did increase the block resistance, it always came at the expense of significant reduction in scrub resistance. Tsang et.al., found that all the above strategies increased block resistance compared to conventional VAE on an average by a factor 2-3, but reduced average scrub resistance by more than 60%.2

In this article, we describe a new higher-block-resistance VAE under development that significantly minimizes the trade off between block resistance and scrub resistance in VAE-only paints. Additionally, this new VAE continues to maintain high scrub resistance even in low-sheen paints, enabling the formulator to use a single-VAE binder across all sheens.

Experimental

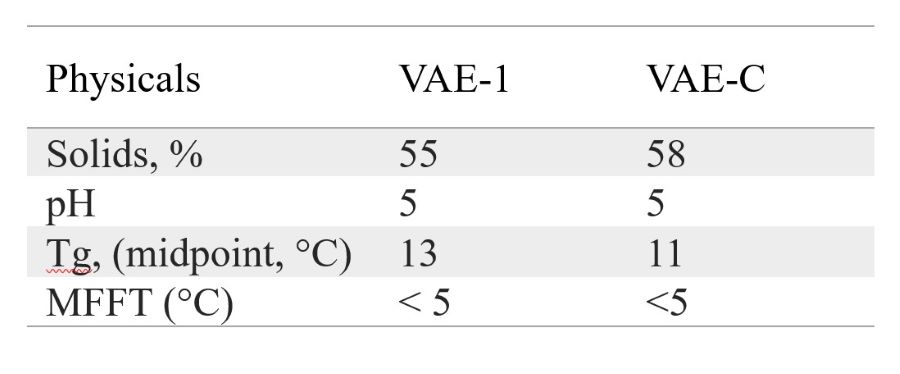

The VAE latexes used were acquired from Celanese Corporation, and their physical properties are shown in Table 1. The VAEs used in this study have different solids, compositions, and morphologies but similar Tg’s and MFFT’s.

TABLE 1 ǀ Physical properties of VAEs used in this study.

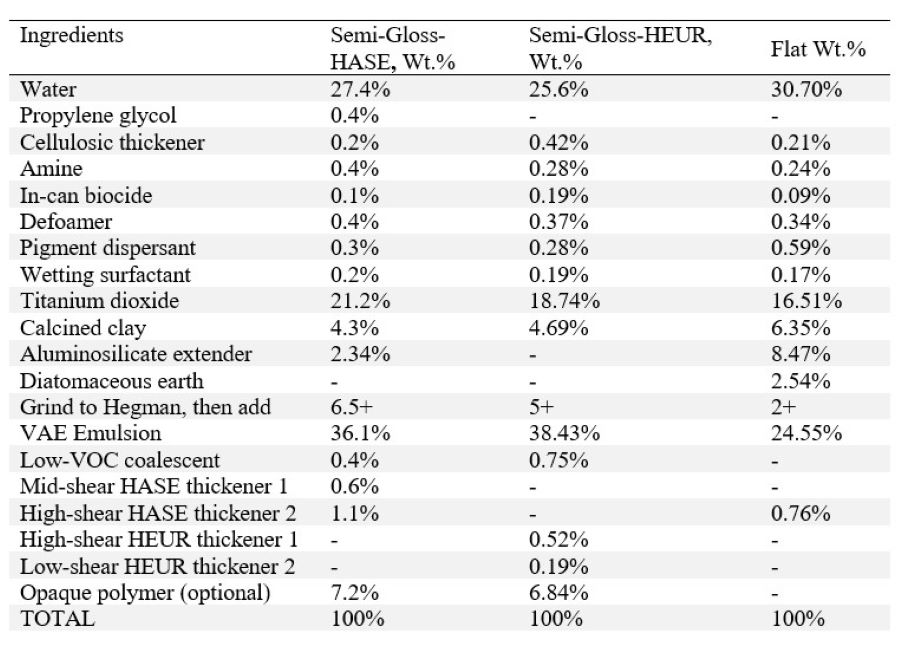

Paint Formulations

The VAE latexes were evaluated in semi-gloss formulations [27-29% pigment volume concentration (PVC) and 40% volume solids] and thickened with either hydrophobically modified alkali swellable (HASE) or hydrophobically modified ethoxylated urethane (HEUR) thickeners, respectively. They were also tested in a flat formulation (55% PVC and 40% volume solids) with an HASE thickener. The formulations are shown in Table 2. Block resistance and scrub resistance were tested according to ASTM D-4946 and ASTM D-2486, respectively. These are generic formulations primarily designed to elucidate the relationship between block and scrub resistance in VAE-only paints. These formulations can be optimized for other properties such as adhesion and stain resistance by careful choice of ingredients.

TABLE 2 ǀ Paint formulations used in this study.

Results and Discussion

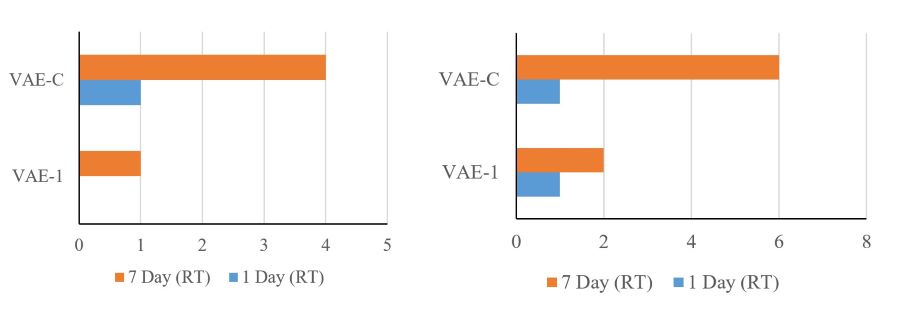

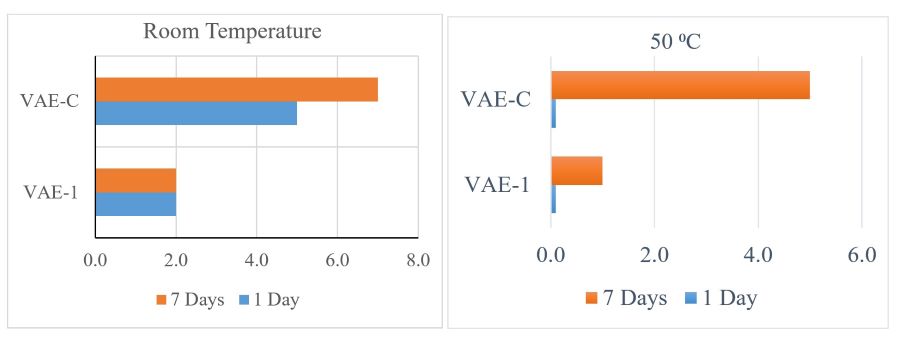

The 1-day and 7-day room temperature block results of semi-gloss paints made with VAE-C and VAE-1 before and after the addition of opaque polymer are shown in Figure 1. The 7-day block resistance significantly improved with VAE-C, even without the addition of opaque polymer. With opaque polymer addition, the 7-day block of VAE-C was around 6, indicating a paint film with low surface tack that does not seal with other surfaces, meeting the typical performance requirement of trim paints. The 1-day block of both VAE’s were lower. This is likely attributable to the softnes of the paint surface due to presence of the coalescent as the paint film has not yet coalesced or dried completely. The block ratings for both VAE’s at 50 ⁰C were essentially 0, as the paint surfaces stuck to each other and were completely inseparable.

FIGURE 1 ǀ Room temperature block resistance of semi-gloss paints with HASE thickener, without and with opaque polymer.

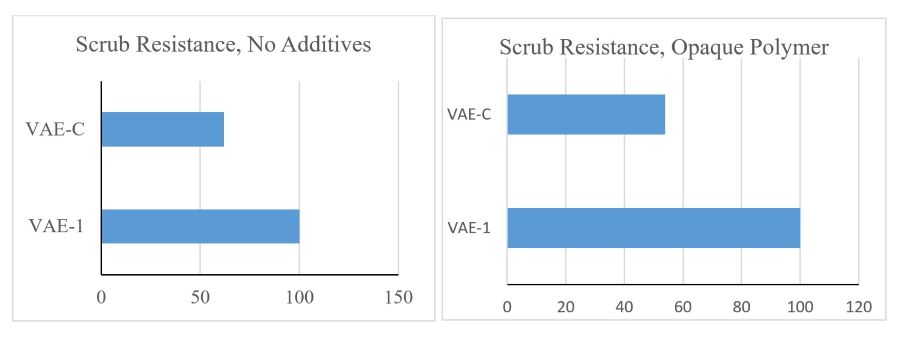

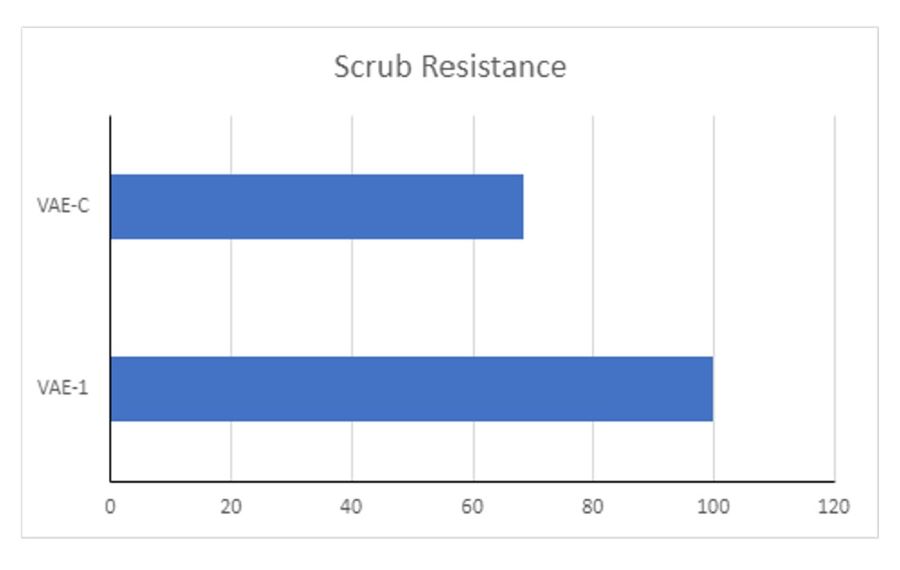

Durability of a paint to abrasive scrub media is often used as a measure of paint quality. VAE paints, in general, show excellent scrubbability compared to acrylics and vinyl acryics due to their toughness and elasticity. Since block and scrub resistance are typically inversly correlated, it is important that strategies for increasing block resistance do not reduce scrub resistance significantly, reducing the overall quality of paint. Scrub resistance results of semi-gloss paints made with HASE thickener before and after adding opaque polymer are shown in Figure 2. The scrub resistance of higher-blocking VAE-C was about 60% of the VAE-1 control before the addition of opaque polymer, and it decreased slightly to about 55% after opaque polymer addition. While the scrub resistance of VAE-C is measurably lower compared to VAE-1, it is still higher than VAE/acrylic blends and harder VAEs made with previous strategies.

FIGURE 2 ǀ Scrub resistance of semi-gloss paints with HASE thickener, without and with opaque polymer.

The higher-block VAE was also tested in another semi-gloss formulation with HEUR thickeners after 1 day and 7 days, respectively. Figure 3 shows the room temperature and 50 ⁰C block resistance of VAEs without any opaque polymer addition after 1-day and 7-days curing. At room temperature, the block resistance of VAE-C was consistently higher, both after 1-day and 7-days drying, with the 7-day sample showing only minimal tack and no sealing. As expected, the 50 ⁰C block resistance was somewhat lower with VAE-C showing the 7-day block around 5. Neither VAE-C nor VAE-1 showed measurable block at 50 ⁰C after 1 day. Presumably, higher temperature and shorter curing time after 1 day made the VAE surface very tacky, giving significantly lower block values for both. Scrub resistance of VAE-C in the semi-gloss paint with HEUR thickener was around 70% of VAE-1 control (Figure 4). Consistent with the observation made in the semi-gloss HASE formulation, the trade off between scrub and block resistance is somewhat minimized in the semi-gloss HEUR formulation also with VAE-C.

FIGURE 3 ǀ Room temperature and 50 ⁰C block resistance of semi-gloss paints with HEUR thickener after 1 day and 7 days, respectively.

FIGURE 4 ǀ Scrub resistance of semi-gloss paints with HEUR thickener.

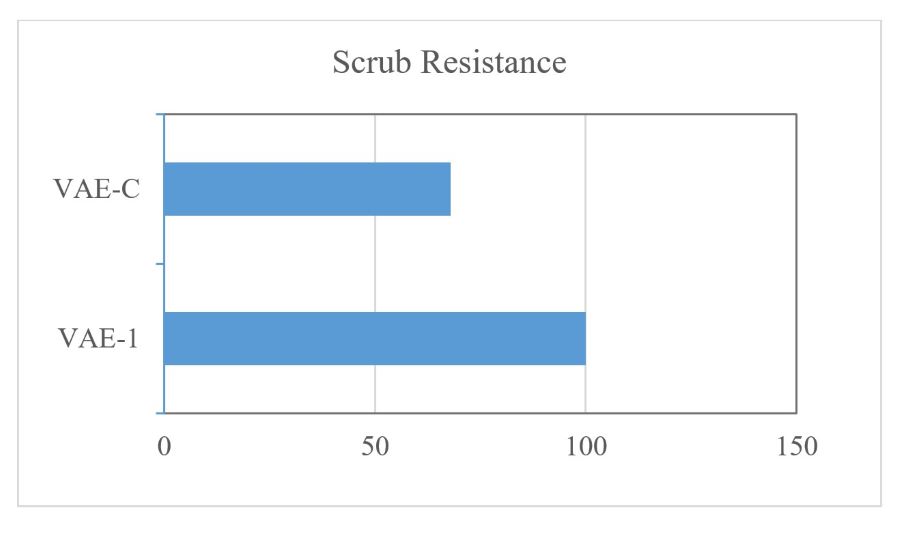

Having to use multiple binders in a formulation increases the logistical complexity for the formulator and can be a source of error. Also, paint manufacturers often cannot afford to deploy more than one storage tank for each binder chemistry. So it is vitally important that the performance of higher-block VAE is consistent across all sheens, including lower sheens such as flat paint. Figure 5 compares the scrub resistance of VAE-C against control, VAE-1 in a 55% PVC flat formulation. VAE-C continues to maintain about 65% of the control scrubs in flat formulation, also. From the above data it is clear that VAE-C shows consistently minimal trade-off between block and scrub resistance across semi-gloss to flat sheens.

FIGURE 5 ǀ Scrub resistance of VAE in 55% PVC flat formulation.

Conclusions

VAE emulsions show outstanding scrub resistance in paints, but at higher sheens, the surface tack of VAE prevents the development of block resistance. We have demonstrated that the strategies we have used to improve VAE block resistance in higher-sheen paints have come at a relatively lower penalty for scrub resistance compared to previous approaches described in the literature. It appears that our approach is striking the right balance between increasing surface hardness of the film that boosts block resistance, while minimally reducing toughness and elasticity of the latex film that contributes to lowering scrub resistance.

References

- Krieger, S.; Petri, H. Soft Vinyl-Acetate/Ethylene Emulsions for High-Performance, Environmentally Friendly Interior Paints. European Coatings Journal 2007, 44-48.

- Tsang, M.; Raman, N.; Martin, J.; Carter, B.; Farwaha, R.; Wenzel, K.; Mueller, H. Technology Advancement to Enhance Versatility of VAE in Architectural Paint. American Coatings Conference 2018.

- Wu, W.; Olesen, K.; Miner II, A.; Schneider, J. Blending Vinyl-Acetate/Ethylene and Acrylic Latexes to Achieve Targeted Performance Properties. JCT Coatings Technology 2007, 44-52.

- Farwaha, R.; Krieger, S.; Gohr, K.; Petri, H.; Fichtner, T.; Rumrich, S. New Developments in Vinyl Acetate-Ethylene (VAE) Co-Polymers for Use in Architectural Coatings, Coatings Tech 2012.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!