Nanotechnology in the Coatings Industry

Nanotechnology is an emerging field that is becoming important in enabling breakthroughs of new and effective tools in the coatings industry. Nanotechnology is concerned with creating and applying structures and devices with organizational features at the intermediate size between individual molecules and about 100 nm, where unique qualities emerge in comparison to bulk materials. Nanotechnology denotes the ability to construct tailored nanostructures and devices for specific tasks through atomic and molecular control.

Coatings provide two primary functions: decoration and protection. Approximately 52% of all coatings produced globally are used to decorate and protect new construction and maintain the existing structures. Around 35% of the coatings are utilized to decorate and/or protect industrial products. The coatings sector in the United States, Western Europe, and Asia Pacific is mature and generally reflects the strength of the economy, particularly housing, building, and transportation. The major coating manufacturers are heavily investing in research and development to formulate compatible and suitable coatings for today’s aggressive environment. Many coating systems have good chemical properties but inferior weathering properties or may not have good thermal stability and mar resistance properties. Nanotechnology can fill the space in the formulation, satisfying the preceding conditions.

Nanocoatings are produced by shrinking the material at the molecular level to form denser products. Nanotechnology can upgrade the properties of the coating system and can produce a multi-purpose coating with little cost difference. Nanocoatings are made of self-assembling monolayers and are applicable in many ways, including scratch-resistant coatings on glass, self-cleaning surfaces, and moisture-absorbing, anti-graffiti, and corrosion-resistant coatings. Nanoparticles such as Nano-ZnO are non-toxic in nature and thus add advantages to the coatings industry.

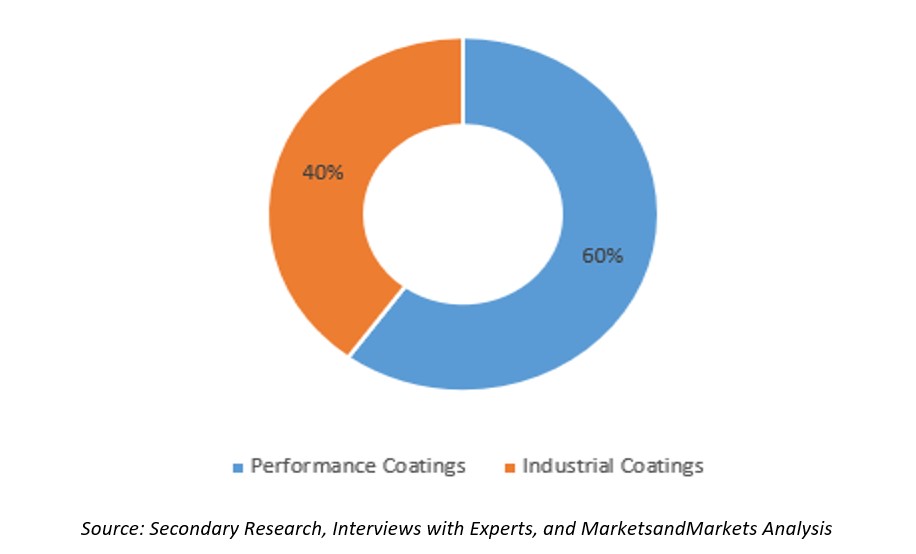

Figure 1| Performance coatings to lead the coatings market in 2022.

Functional Coatings are the Primary User of Nanotechnology

Nanotechnology has been extensively incorporated into functional coatings, including hydrophobic, hydrophilic, and photocatalytic coatings, coatings for reducing surface solar radiation, and phase change material (PCM) coatings. Functional coating materials based on nano-composites can be created and subsequently coated over surfaces. Deposition techniques, on the other hand, can be used to build, change, or manipulate the surface structures of coating materials at the nanoscale. Hydrophobic coatings are presently used in a variety of industrial applications such as textiles, surgical tools, medical equipment, and buildings. With the capacity to repel water, there is a lot of interest in developing coatings that have additional functions, including self-cleaning, anti-bacterial, anti-corrosion, and anti-icing. Superhydrophobic coatings have attracted a lot of attention because of their unique properties, such as self-cleaning, anti-sticking, and anti-contamination.

Fluorinated polymers are used to manufacture superhydrophobic surfaces due to their low surface energies. Apart from fluorocarbons, polytetrafluoroethylene (PTFE) is widely used as a coating for anti-adhesion agents and chemical insulators. With the development of new materials and technologies, surface preparation methods of superhydrophobic coating have become more diverse and in-depth. With the development of nanotechnology, solid particle spraying is expected to replace liquid spraying methods in the superhydrophobic coating. The advancements in biotechnology have resulted in the synthesis of many new biomaterials, which are expected to replace some toxic chemical reagents, resulting in environmentally friendly superhydrophobic surfaces.

Hydrophilic coatings exhibit water-loving properties, indicating that they participate in dynamic hydrogen bonding with the surrounding water. Most hydrophilic coatings are also ionic and frequently negatively charged, which enhances water interactions even more. Hydrophilic coatings find use in medical devices, aerospace, automotive, optics, and marine. In a recent study, it has been suggested that the hydrophilicity of the coating can be significantly improved by using dendritic silica nanoparticles. Researchers were drawn to silica nanoparticles because of their good features such as volume effect, surface effect, quantum size effect, and numerous hydroxyl groups on the surface, making them hydrophilic. In most research, the major raw material utilized to make super-hydrophilic coatings is spherical colloidal silica, and the coatings must subsequently undergo a high-temperature heat treatment. One of the primary difficulties affecting the coating's practical applications is its weak mechanical qualities, making it difficult for the coating to be widely utilized.

Table 1| Global hydrophilic coating market snapshot.

New Developments in Nanotechnology

Nanotechnology, which has had a major effect on the development of coating technology has recently led to new developments among manufacturers.

- Tang's group has created a number of fire-retardant coating materials that are based on silicone resin polymer foam composites, polydimethysiloxane/graphene foam nanocomposites, water-based clay/graphene oxide (GO) nanoribbon network, and GO/melamine sponge composites, as well as fire warning coatings that are based on GO wide-ribbons wrapped sponge and GO network.

- Coat-X SA has developed silicon-based conformal coating that can be used to make complex 3D surfaces highly hydrophobic. The coating can be applied on the surfaces of glass, polymers, fabrica and printed circuit boards (PCBs).

- Cortec MCI launched EcoAir Biobased outdoor coating enabled by Nano VpCI, a biobased temporary coating intended for use in harsh marine and high humidity environments. It leaves an oily protective film that does not dry and is temperature stable up to 180 degrees Fahrenheit (82 degrees Celsius). It can be used to apply a fast layer of rust prevention to virtually any metal part that requires protection, including nuts and bolts, spare car parts, and other exposed metal surfaces. It's also perfect for rapid temporary touchups on equipment where chipped paint can't be replaced right away.

- Signo-Nanocare UK Ltd. launched Nanoflex Optiperl, a fluorine-free nano-coating that gives glass and ceramic surfaces the optimum ‘easy-clean’ finish. The optimized hydrophobic quality of Nanoflex Optiperl ensures that dirt particles rarely adhere to the coated substrate.

The trends and developments mentioned are a few hot bets expected to impact the coatings industry in the coming years. Companies that stay informed and proactive in responding to these changes are expected to be well-positioned to succeed in the exciting and ever-evolving market.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!