Nature’s Brush: Harnessing Bio-Surfactants for Innovative Paint and Coatings

March 5, 2024

Nature’s Brush: Harnessing Bio-Surfactants for Innovative Paint and Coatings

March 5, 2024Surfactants play a crucial role in the formulation and application of paints and coatings. These chemical compounds, also known as surface-active agents, are added to paint and coatings formulations to modify the performance properties of the finished formulation.

Surfactant Applications

Surfactants are primarily used to reduce the interfacial surface tension. The interfacial tension can happen at any interface, whether internal or external. The reduction in surface tension helps the material spread evenly across the surface. They can act as wetting agents by improving the ability of the paint or coating to wet the substrate, which ensures that the material spreads and adheres to the surface, reducing the formation of defects like pinholes, craters, or fisheyes. They can improve the final finish by serving as anti-cratering agents, reducing the formation of craters on the coating surface, which can occur due to trapped air or contaminants, enhancing the flow and leveling properties of paint, allowing it to spread smoothly and evenly over the surface. This results in a more aesthetically pleasing and uniform finish. Surfactants can improve the adhesion of the paint or coating to a wide range of substrates, including metal, plastics, and wood.

Through the proper selection of surfactants, formulators can also control and/or minimize foam formation during the mixing, application, and drying processes. Excessive foam can lead to uneven application and surface imperfections. And in some cases, surfactants with specific chemical properties are incorporated into coatings to provide corrosion inhibition and extend the lifespan of the coated surface.

Surfactants are essential for dispersing pigments and fillers within the paint or coating as well. Proper dispersion ensures color consistency, opacity, and overall coating performance. Dispersant selection can have a big impact on water resistance and water spotting performance. In water-based paints, surfactants are often used to stabilize resin emulsions by keeping the water and oil phases of the paint well-dispersed, preventing separation over time.

Selection Concerns

While performance is generally the number one selection criteria for paint and coatings formulations, manufacturers often consider environmental and regulatory factors. Some surfactants may be chosen for their bio-degradability or compliance with environmental regulations.

Surfactants are versatile additives, influencing various aspects of the formulation and application process. They help improve the performance, appearance, and durability of coatings while addressing issues such as surface tension, wetting, foam control, and adhesion. Proper selection and incorporation of surfactants are crucial for achieving the desired properties in paints and coatings, while adhering to industry standards and regulations.

Are There Greener Surfactant Alternatives?

While traditional petro-chemical surfactants have been widely used in various industries, including cosmetics, detergents, and paints and coatings, there are several challenges associated with their use. These challenges, coupled with increasing environmental concerns and the demand for sustainable products, have led to a growing pressure to transition to bio-based surfactants.

Traditional Surfactant Concerns

Traditional surfactants can have adverse effects on the environment due to their non-biodegradable nature. They can persist in waterways, soil, and ecosystems, leading to long-term environmental damage. And some traditional surfactants may even be toxic to aquatic life and have harmful effects on human health if not properly handled or disposed. Because petrochemical surfactants are derived from fossil fuels, which are finite resources, the reliance on non-renewable feedstocks raises concerns about the long-term availability and sustainability of these materials.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

External Pressures

Governments and regulatory bodies are increasingly imposing stricter regulations on the use and disposal of certain traditional surfactants due to their potential environmental and health risks. Consumer awareness and demand for environmentally friendly and sustainable products have also put pressure on industries to adopt more sustainable practices, including the use of bio-based surfactants.

Bio-Based Surfactants

Bio-based surfactants are often derived from renewable resources, such as plant oils, and they tend to be more biodegradable, reducing their environmental impact. However, one challenge in transitioning to bio-based surfactants is ensuring they offer comparable performance and compatibility with existing formulations. Manufacturers need to find bio-based alternatives that meet the technical requirements of their products. Additionally, bio-based surfactants can sometimes be more expensive to produce than their chemical counterparts, and there may be challenges in establishing a reliable supply chain for bio-based feedstocks. Developing and scaling up bio-based surfactants often requires significant research and development efforts, which can be time consuming and costly. Some industries have been slow to adopt bio-based alternatives due to existing infrastructure and a resistance to change. However, as sustainability becomes a more prominent concern, this resistance is gradually diminishing.

In response to these challenges, there is a growing interest in developing and using bio-based surfactants that offer similar or improved performance while addressing environmental and sustainability concerns. These bio-based alternatives are derived from renewable resources, are often biodegradable, and have the potential to reduce the environmental footprint of various products and processes. As consumer and regulatory pressure for sustainability continues to grow, industries are increasingly motivated to explore and integrate bio-based surfactants into their formulations.

What Are the Differences Between Bio-Based Surfactants and Bio-Surfactants?

In an effort to increase environmental responsibility while meeting regulatory requirements and stakeholder demands, many surfactant producers have sought to replace petrochemical-based raw materials with bio-based, renewable feedstocks. These sustainable replacements to traditional, petrochemically based surfactants are known as bio-based surfactants.

The USDA defines bio-based surfactants as those that are derived “… in whole or significant part of biological products or renewable domestic agricultural materials (including plant, animal, and marine materials) or forestry materials.” In short, all bio-based surfactants are created at least in part from bio-based, renewable feedstocks and raw materials.

There are many different types of bio-based surfactants, the most sustainable of which is a classification known as bio-surfactants. Unsurprisingly, with these new developments has come some confusion in terminology, both with product formulators as well as among end users.

Key Differences

Bio-surfactants are a type of bio-based surfactant. Unfortunately, some manufacturers refer to their bio-based surfactants as bio-surfactants, further confusing the terminology. It’s important to note that all bio-surfactants are bio-based surfactants, but not all bio-based surfactants are bio-surfactants.

There are two key differences between bio-based surfactants and bio-surfactants that end users may not realize:

- The bio content.

- How the surfactant is produced.

Based on these two factors, bio-surfactants have proven sustainability and performance advantages compared to bio-based surfactants.

Bio-Based Content

While all bio-based surfactants contain carbon derived from renewable sources, some also contain carbon from fossil fuels. Classifications have been developed to rank bio-based surfactants based on their starting materials. Two examples include:

- The Renewable Carbon Index (RCI), which grades bio-based surfactants based on their bio content, or the percentage of total carbon derived from plant or agricultural-based sources as opposed to carbon from fossil fuels.

- The European Commission of Standardization (CEN), which classifies surfactants into four categories based on the percentage of renewable carbon (carbon derived from renewable feedstocks) that they contain.

Unfortunately, classifications like these may be confusing to manufacturers and consumers because they allow surfactants to be categorized as fully bio-based even if they contain fossil fuel-based materials. For example, CEN considers a surfactant “wholly bio-based” as long as it contains more than 95% renewable carbon.

Chemical Surfactant Production

Manufacturers of bio-based surfactants advertise their products as a sustainable alternative to traditional surfactants. However, the production of many bio-based surfactants requires traditional chemical reactions. These reactions consume substantial levels of heat and electricity generated by hydrocarbon sources, leaving a larger carbon footprint.

How Are Bio-Surfactants Gaining Traction in Paint and Coatings Formulations?

Bio-surfactants are gaining attention as a top alternative to chemical surfactants, especially in industries like paints and coatings, where sustainability and environmental concerns are increasing. Bio-surfactants are surface-active compounds produced by microorganisms (bacteria, yeast, fungi, etc.) and derived from renewable biomass sources like plants and algae. They offer several advantages as alternatives to chemical surfactants and can perform effectively in paint and coatings applications.

Advantages of Bio-Surfactants

One of the most significant advantages of bio-surfactants is their biodegradability. They break down naturally into non-harmful components, reducing their environmental impact compared to many chemical surfactants. Bio-surfactants are often less toxic to humans and the environment than some chemical surfactants, making them a safer option for handling and disposal. Bio-surfactants are derived from renewable resources, such as plant oils or agricultural byproducts, which are more sustainable, and contribute to reducing dependence on fossil fuels.

Using bio-surfactants in water-based coatings can help reduce volatile organic compound (VOC) emissions, which is crucial for meeting environmental regulations and improving indoor air quality. Bio-surfactants can be compatible with a wide range of coatings formulations, making them versatile additives that can be integrated into existing products with minimal formulation adjustments. Certain bio-surfactants are known for their resistance to extreme conditions, such as high salinity, temperature or pH levels, making them suitable for challenging coating applications. The use of bio-surfactants aligns with sustainability goals and can be marketed as an eco-friendly feature of paint and coatings, appealing to environmentally conscious consumers.

Importance of Research and Testing

It is important to note, however, that the performance of bio-surfactants in paints and coatings may vary depending on factors such as the specific type of bio-surfactant, the coating formulation, and the application conditions. Therefore, extensive research and testing are necessary to identify the most suitable bio-surfactant for a particular application.

What Makes Locus Ingredients’ Bio-surfactants Different?

Many bio-based surfactant suppliers advertise their products as providing an environmentally sustainable alternative to conventional options. But not all bio-based surfactants are created equal. Only bio-surfactants minimize environmental impact from production to end use while delivering proven performance gains for CPG and industrial suppliers.

U.S.-based supplier Locus Ingredients produces commercial volumes of bio-surfactants, specifically sophorolipids (SLP), that are used globally in industrial and CPG applications, including:

- Coatings, adhesives, sealants and elastomers (CASE);

- Industrial and institutional cleaning products (I&I);

- Agricultural adjuvants;

- Metalworking fluids;

- Industrial treatments for water, pulp & paper, and textile & leather,

- Personal and home care products (available through Dow).

The company’s microbial sophorolipids, a type of bio-surfactant in the glycolipid class, are produced using novel fermentation methods with a low carbon footprint and are USDA certified as 100% bio-based. The high activity bio-surfactants can be customized to solve a multitude of formulation pain points, including:

- Replacing palm oil-based and petrochemical ingredients;

- Minimizing toxicity;

- Maximizing product performance;

- Reducing carbon intensity.

Case Study: Preliminary Pigment Dispersant Evaluation for CASE Applications

This case study focuses on the evaluation of pigment dispersants in coatings, specifically in the context of titanium dioxide (TiO2) slurry formulations and resinless pigment dispersions. The study explores the performance of TiO2, various organic pigments, and carbon black, with future investigations into inorganic pigments and metallic pigments planned. The primary objective of this study is to assess the effectiveness of these dispersants in terms of their impact on key properties of dispersions and understand their potential contribution to performance.

Method

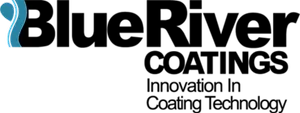

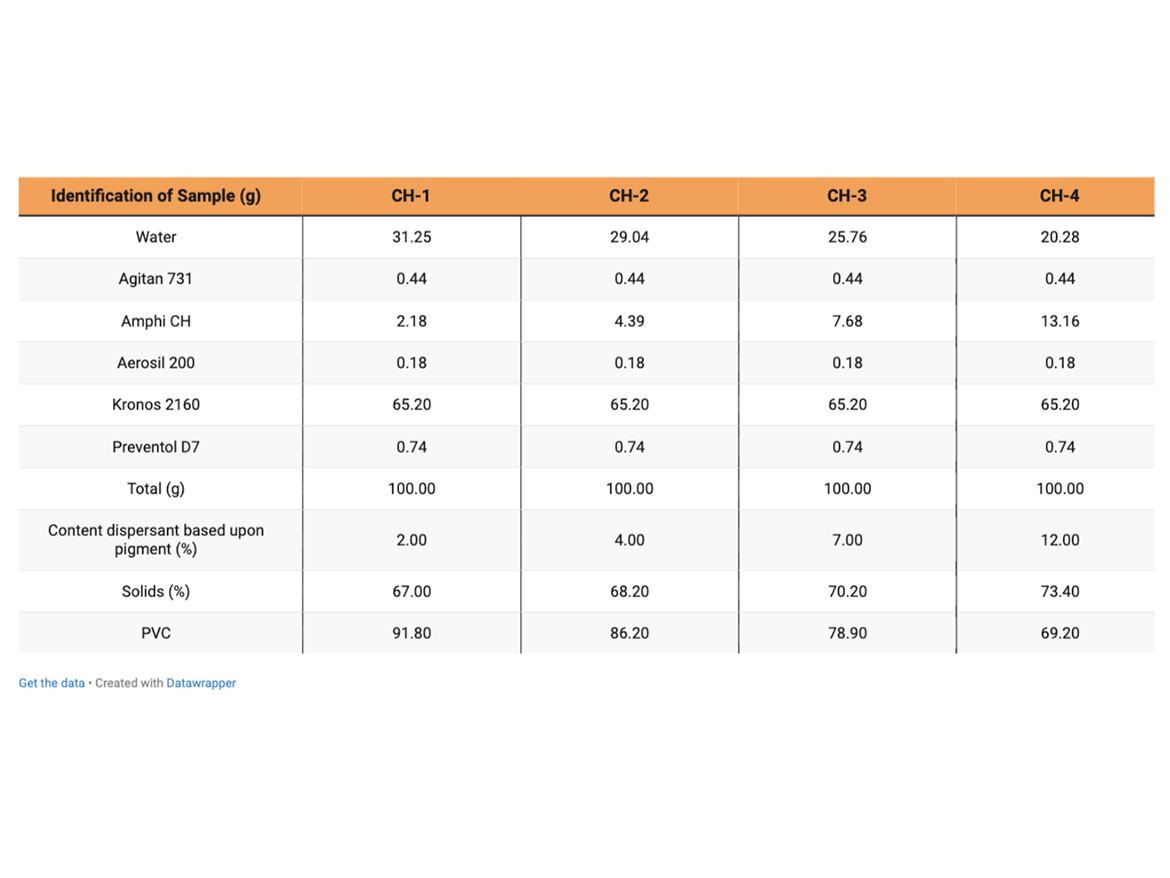

Locus Ingredients commissioned a third-party laboratory evaluation of both Amphi® CL (lactonic sophorolipid) and Amphi® CH (linear sophorolipid) as a dispersant for TiO2 (Kronos 2160) in a slurry formulation. The evaluation was carried out with formulations (Tables 1 and 2), varying addition level of additive to identify optimal usage. Slurries were processed using a Netzsch pearl mill at 1,000 rpm for 30 minutes.

Findings

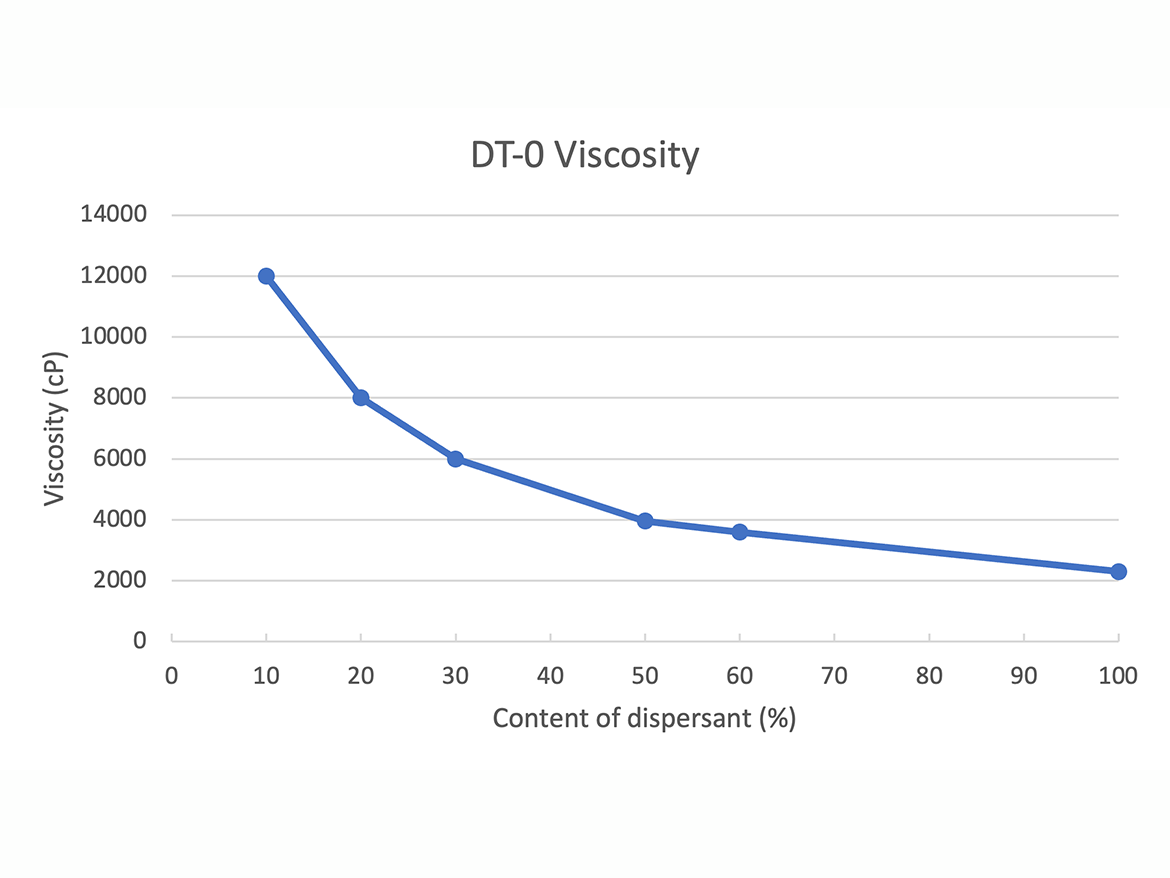

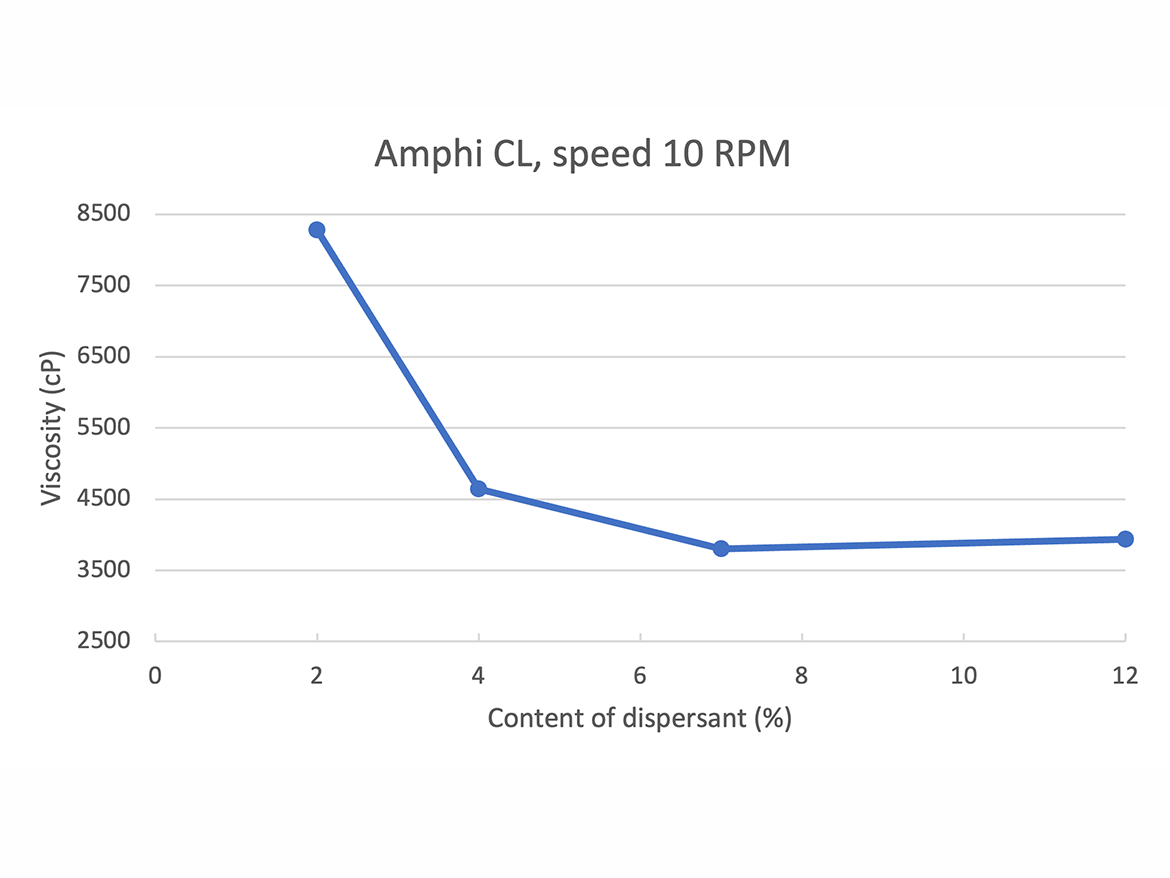

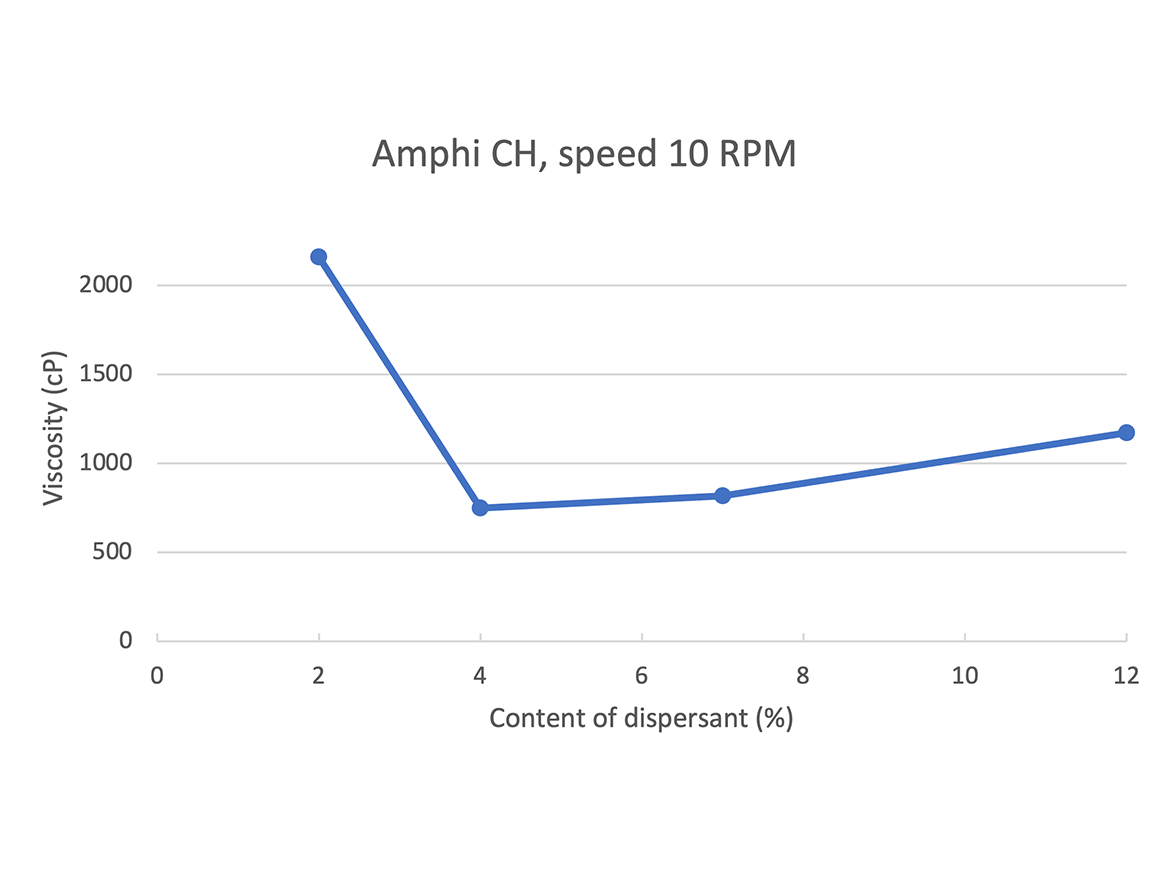

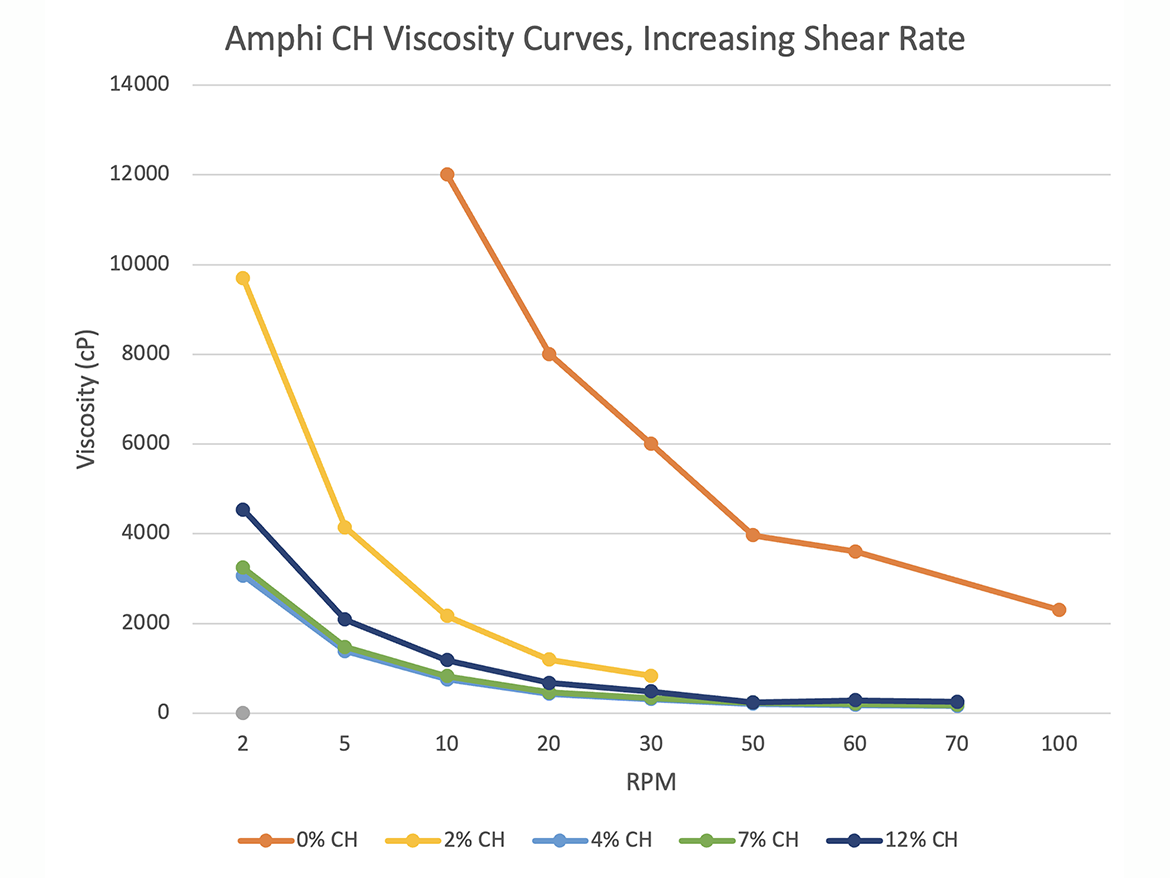

One of the notable trends observed in this study is the reduction in viscosity when using these dispersants. This reduction in viscosity can have significant implications for the ease of application and the overall quality of the coatings. Additionally, the dispersants have been found to contribute to reduced particle sizes and improved particle size stability over time, particularly when subjected to heat-accelerated aging. These characteristics are crucial for maintaining the performance and appearance of coatings over their lifecycle.

As can be seen from the graphs, the linear sophorolipid outperformed the lactonic sophorolipid in regard to viscosity reduction. Optimal viscosity performance was shown at 4% addition level based on pigment weight in this particular formulation. Additional factors play a part in optimization in final formulation (hiding power, physical properties, colorant acceptance, resistance properties (scrub resistance), etc.). But as a basic indicator, viscosity reduction shows the dispersant’s ability to help separate and stabilize particles.

Conclusion

In summary, bio-surfactants offer a promising alternative to chemical surfactants in the paint and coatings industry due to their bio-degradability, low toxicity, renewable feedstocks, and enhanced performance in various aspects of coatings formulations. As sustainability continues to drive innovation in the industry, bio-surfactants are likely to play a more significant role in the development of eco-friendly and high-performance coatings.