Industrial: Innovative Approaches to Water-Based DTM Coatings

Formulating for Corrosion Resistance and Adhesion

RoschetzkyIstockPhoto / Vetta via Getty Images

Direct-to-metal (DTM) coatings are commonly used to protect a metal substrate. Over the past decade, due to increased regulatory scrutiny of solventborne coatings, formulators have been transitioning to water-based systems where feasible. Water-based coatings tend to have lower volatile organic compound (VOC) content, as water serves as the primary liquid medium rather than volatile organic solvents. However, formulating water-based DTM coatings presents challenges, as water can initiate corrosion processes on metal substrates. Therefore, the choice of resin and the selection of additives significantly influence the final performance properties.

The resin used in a coating has a substantial impact on product performance. Selecting a resin specifically designed for DTM coatings — offering corrosion resistance, water resistance and adhesion to a variety of metallic substrates — is critical. Additionally, a resin that can withstand various coating ingredients and be formulated to achieve different sheens and pigment levels is desirable. Once a resin is selected, the choice of additives further affects the final coating performance.

Experimental Design and Methodology

This study employs a four-factor fractional factorial design of experiments (DOE) to examine the influence of a coalescent, dispersant, pH buffer agent and corrosion inhibitor on the performance properties of a DTM coating formulation. The resin selected is a waterborne styrene-acrylic resin formulated at less than 100 g/L VOC.

The DTM resin is a high-solids styrene-acrylic emulsion supplied at 50 wt% solids. The minimum film formation temperature (MFFT) is +20 °C and requires approximately 12.5% dipropylene glycol butyl ether (DPnB), based on resin solids, for low-temperature coalescence. This DTM emulsion provides high gloss while also offering block resistance and adhesion. Table 1 presents the physical properties of the emulsion.

The polymer was specifically developed for DTM coatings, such as those used in implement repairs and light-duty industrial maintenance. Since DTM coatings may be exposed to exterior conditions, they must exhibit good gloss and color retention. Additionally, these coatings should demonstrate strong adhesion in both dry and wet environments while resisting rust formation.

To evaluate DTM coating corrosion resistance, the study employed salt spray resistance and electrical impedance spectroscopy (EIS).

A DTM high-gloss white enamel formulation was used for the study, detailed in Table 2. The materials highlighted in bold are the additives investigated. Table 3 outlines the physical specifications of the high-gloss white paint.

The DOE treatments, including the four factors, are presented in Table 4. The first factor, coalescing agent types, were selected from butyl carbitol (DB), a miscible solvent, or dipropylene glycol butyl ether (DPnB), an immiscible solvent. The second factor explored was the dispersant type. In this investigation, a hydrophobic dispersant supplied at 21.5% active solids and a hydrophilic dispersant supplied at 50% active solids were used. The third factor investigated was the selection of the neutralizing agent, either a 21% solution of ammonium hydroxide, a volatile buffer, or a 5% sodium hydroxide solution, which is nonvolatile. The final factor examined in this study was the use of a corrosion inhibitor, an amino carboxylate salt, at 20.5% active solids.

Test Methods

The performance of the DTM paint samples was evaluated using the following test methods:

Electrochemical Impedance Spectroscopy (ASTM D8370)

A 10-mil wet film thickness drawdown bar was used to apply a coating to a cold-rolled steel substrate. The film was cured for 7 days in a chamber at 70 °F and 50% RH. After the designated cure time, electrical impedance was measured at a defect-free area using a Gamry Reference 600 Potentiostat with a three-electrode setup, where a platinum mesh counter electrode and an Ag/AgCl reference electrode were used in an electrolyte of 5% NaCl. The frequency range was 100,000 Hz to 0.01 Hz with a perturbation of 5 mV versus OCP. The data shown is the log of the lowest frequency raw impedance output for a surface area of 7 cm².

The reference electrode was Ag/AgCl, the counter electrode was a platinum mesh, and the working electrode was the cold-rolled steel substrate to which the coating was applied. The electrolyte used in this experiment was a 5% NaCl solution. The 5% salt soak was performed for 24 hours at 70 °F and 50% RH, and measurements were determined using a potentiostat for electrical impedance spectroscopy.

Dry Adhesion (ASTM D3359)

Samples were applied to cold-rolled steel panels (Q-panel R46) using a 10-mil drawdown bar and cured in a temperature-controlled chamber, set to 70 °F and 50% RH, for 7 days. After curing, a template was used to scribe a 3 mm crosshatch into the coating. Elcometer Adhesion D3359 tape was pressed directly onto the scribed portion for 15 seconds, ensuring even pressure. The tape was then swiftly removed at a 90° angle. The amount of coating that remained adhered to the substrate after the tape pull was rated on a 0B–5B scale (0B = 0% film retention, 5B = 100% film retention).

Wet Adhesion (ASTM D3359)

Samples were prepared, cured and scribed using the same method as the dry adhesion samples. After scribing, a small piece of paper towel saturated with deionized (DI) water was placed over the crosshatch area and remained on the coating for 30 minutes. After the 30-minute period, the area was lightly blotted dry, and a piece of Elcometer Adhesion D3359 tape was pressed directly onto the scribed portion for 15 seconds, ensuring even pressure. The tape was then swiftly removed at a 90° angle. The amount of coating that remained adhered to the substrate after the tape pull was rated on a 0B–5B scale (0B = 0% film retention, 5B = 100% film retention).

Salt Spray Resistance (ASTM B117, D714, D610)

Coatings were applied to cold-rolled steel (Q-panel R46) using a 10-mil wet film thickness drawdown bar. The panels were allowed to cure for 7 days at 70 °F and 50% RH. A Positector-6000 film thickness meter was used to measure the thickness of each panel. A 3-inch vertical scribe was made in the center of each sample panel. The samples were then placed into a Q-Fog salt fog chamber (model CCT-1100), set according to ASTM B117 (5% NaCl), for 168 hours. After exposure, rust creepage from the scribed line was measured and recorded in millimeters.

Accelerated Weathering (ASTM D5894)

Accelerated weathering samples were drawn down on aluminum (Q-panel) panels at 10-mil wet film thickness and cured at 70 °F and 50% RH for 7 days. The initial gloss at 60° was measured and recorded using a micro-TRI-gloss meter (BYK Gardner). Using a Datacolor colorimeter, the initial LAB values were recorded. The panels were placed into an accelerated weathering chamber (QUVA Q-Lab) under the following cycle parameters:

- 8 hours of UV light at 60 °C

- 4 hours of condensation (no light) at 50 °C

After 504 hours, the gloss and color values were measured and recorded.

Results

Adhesion

The dry adhesion for the formulated coatings showed no variability, achieving 5B (100% adhesion) at 1 day cured and 7 days cured for all samples evaluated. This demonstrates that the styrenated acrylic DTM polymer is robust to formulation modification for dry adhesion.

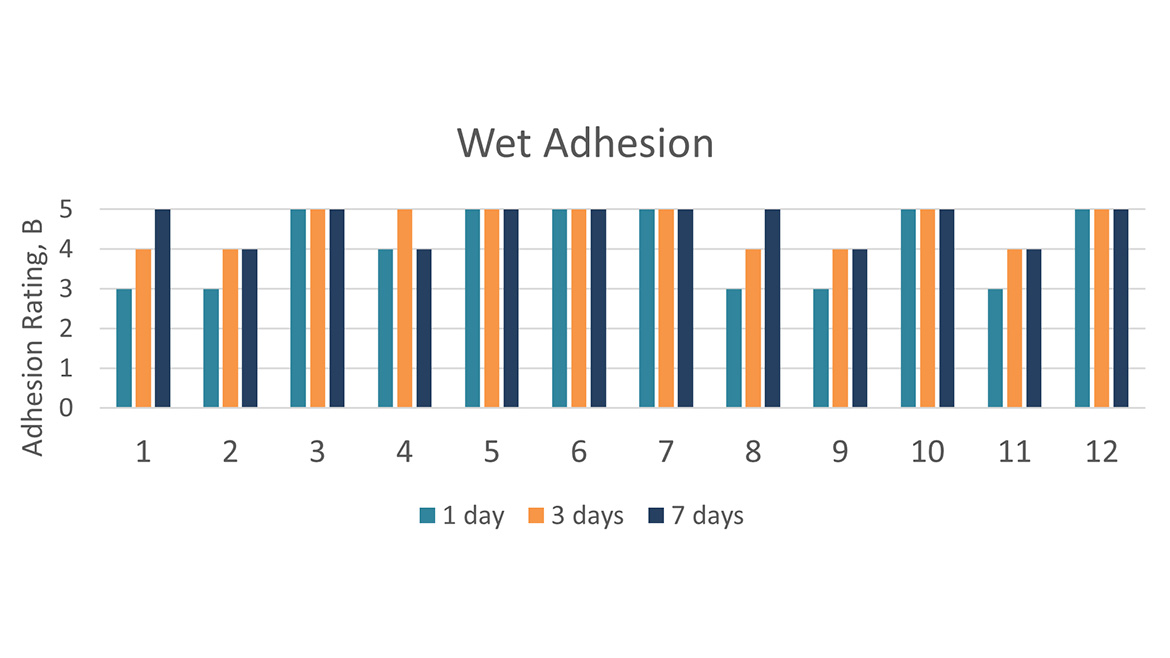

The adhesion in wet conditions showed more variability from 1 day cured to 7 days cured. Figure 1 presents the wet adhesion results for the 12 samples.

Samples either achieved 5B adhesion at 1 day cured or demonstrated an increase in wet adhesion over time. Since most of the adhesion variability occurs at 1 day cure time, this analysis focuses on that time point.

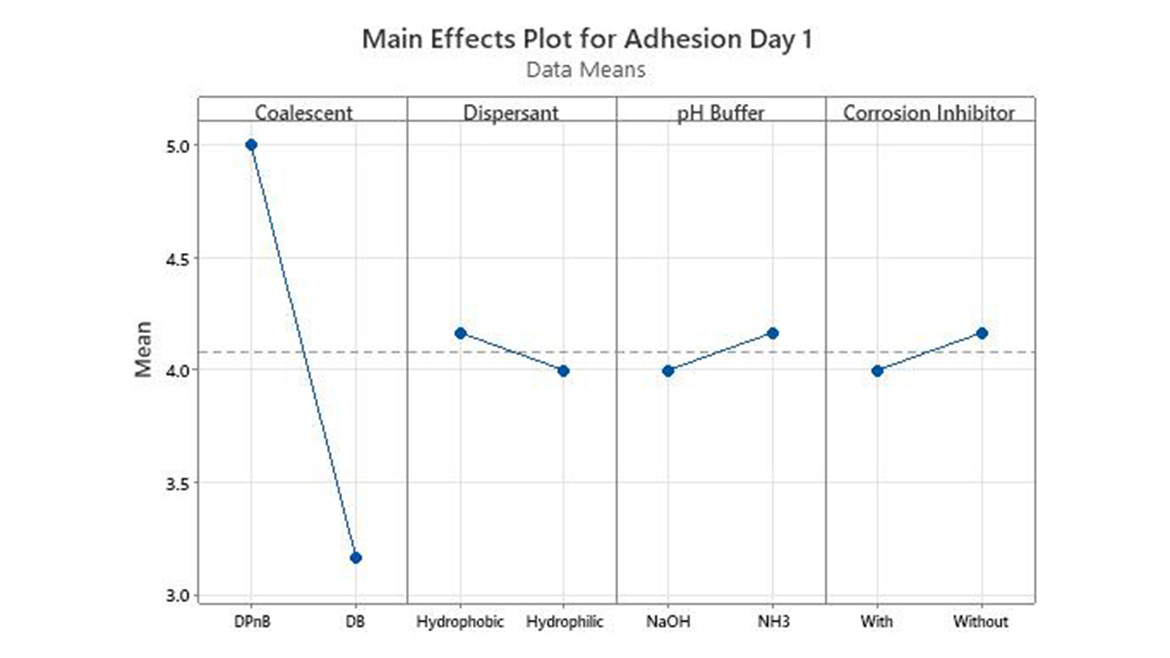

Figure 2 presents the main effects plot for 1 day adhesion. A steep slope in a main effects plot indicates a significant factor affecting the property being analyzed. For 1 day wet adhesion, coalescent choice strongly influenced performance. Samples using the miscible solvent DB yielded a lower wet adhesion rating near 3B, while samples with the immiscible solvent DPnB consistently achieved 5B ratings. However, after 3 and 7 days, variability was reduced, with many formulations achieving 4B and 5B ratings. This early wet adhesion variability may be attributed to residual coalescent remaining in the film after 1 day, which volatilized by 7 days.

Salt Spray

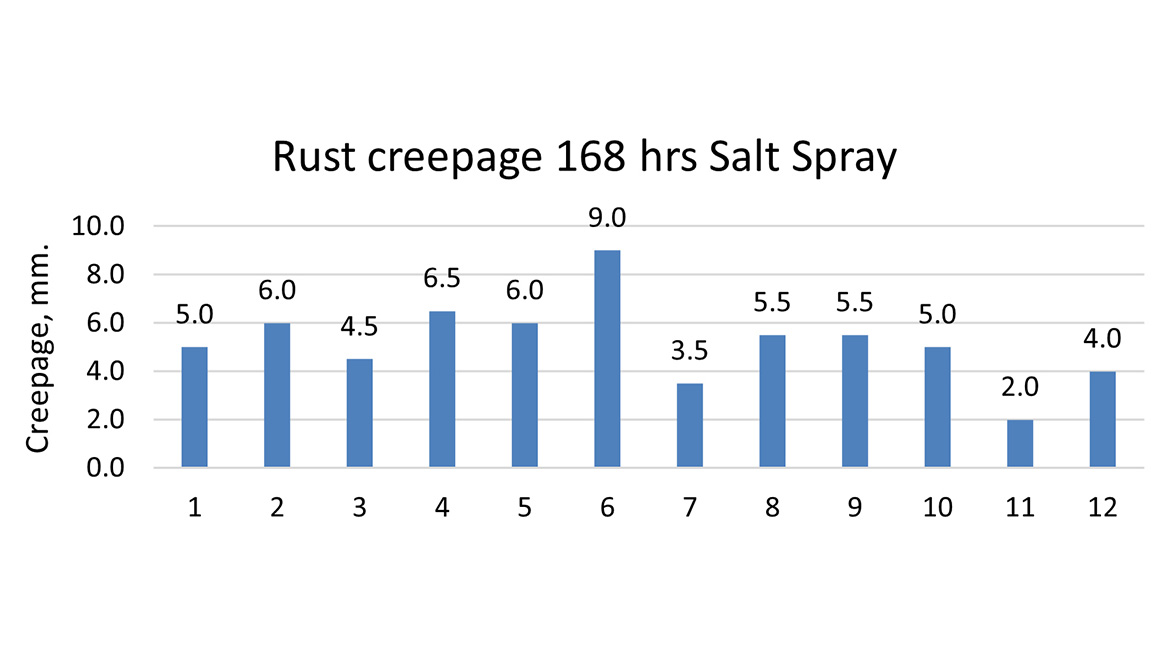

Below in Figure 3 are the results of the DTM samples (2.5-3.0 mil dry film thickness) exposed to 5% NaCl salt spray for 168 hours.

Most samples exhibited strong corrosion resistance and did not show signs of severe failure. None of the samples displayed significant blistering in the field, confirming the robustness of the resin in these formulations.

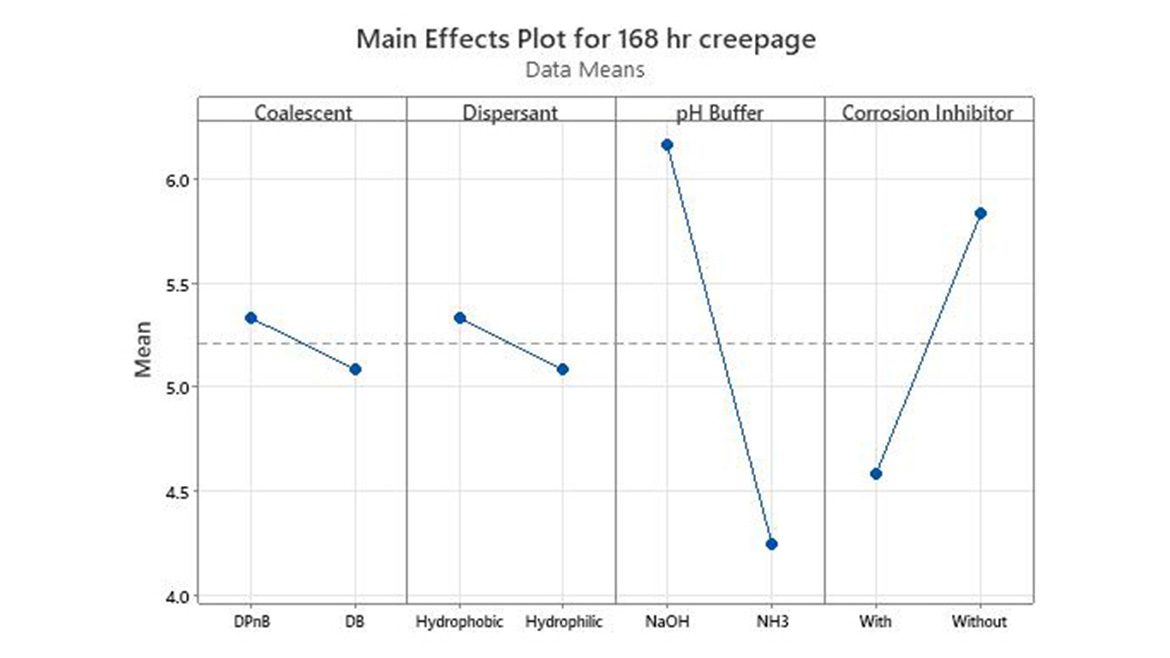

Figure 4 illustrates the rust creepage from the scribe at 168 hours of salt spray exposure. The main effects plot is presented in Figure 5. The main factors impacting rust creepage were neutralizing agent and use of corrosion inhibitor.

The corrosion inhibitor was designed to create the necessary complexes to inhibit corrosion formation, while the volatile behavior of the pH buffer helped eliminate salt residue within the film. In contrast, a nonvolatile buffer created physical pathways that allowed water penetration, leading to corrosion. The use of ammonia as a volatile buffer resulted in lower creepage, as did the presence of a corrosion inhibitor. However, it is noteworthy that samples 2, 3, 4, 6, 7 and 8 did not contain a corrosion inhibitor, yet sample 7 exhibited the second-lowest creep among all evaluated samples. This suggests that effective formulations can be designed without requiring an added rust inhibitor.

Accelerated Weathering

After 504 hours of QUV testing, all samples exhibited color changes with ΔE values below 1.00, indicating minimal impact. The data also revealed that ΔE shifts were primarily driven by ΔB (yellowing); however, the color change was too minor to yield meaningful conclusions. This indicates that none of the factors investigated significantly impacted color, and the polymer tolerated a variety of additives while maintaining color stability.

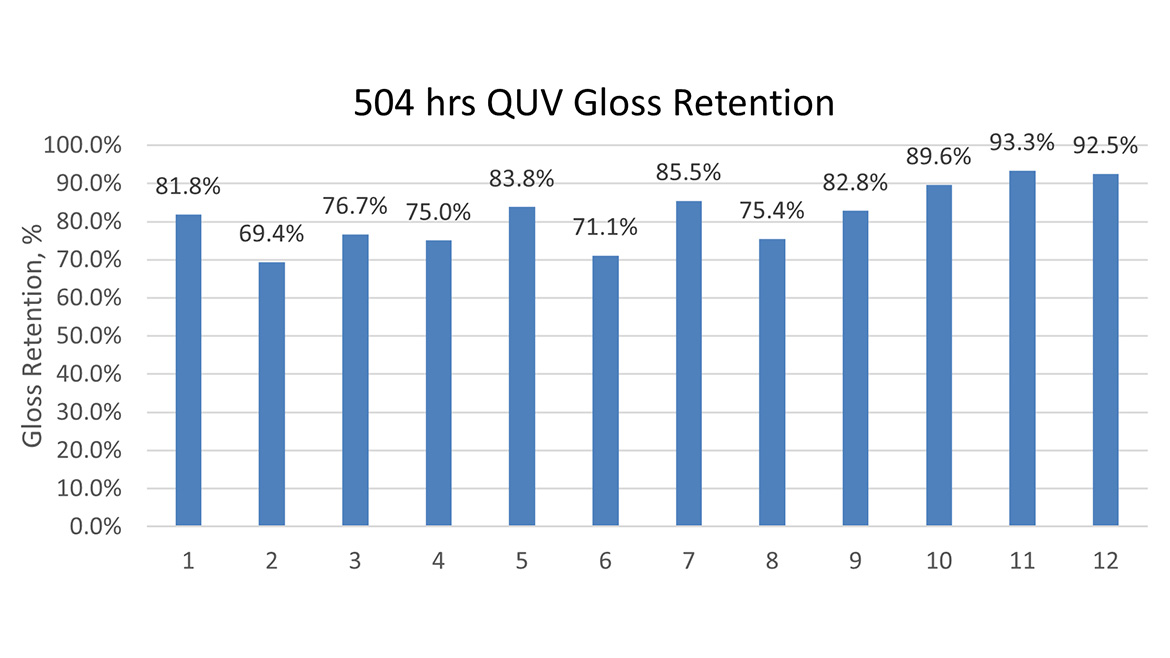

Gloss retention results after 504 hours of QUV cycling are presented in Figure 6, showing retention values ranging from ~70% to 90% at 60°.

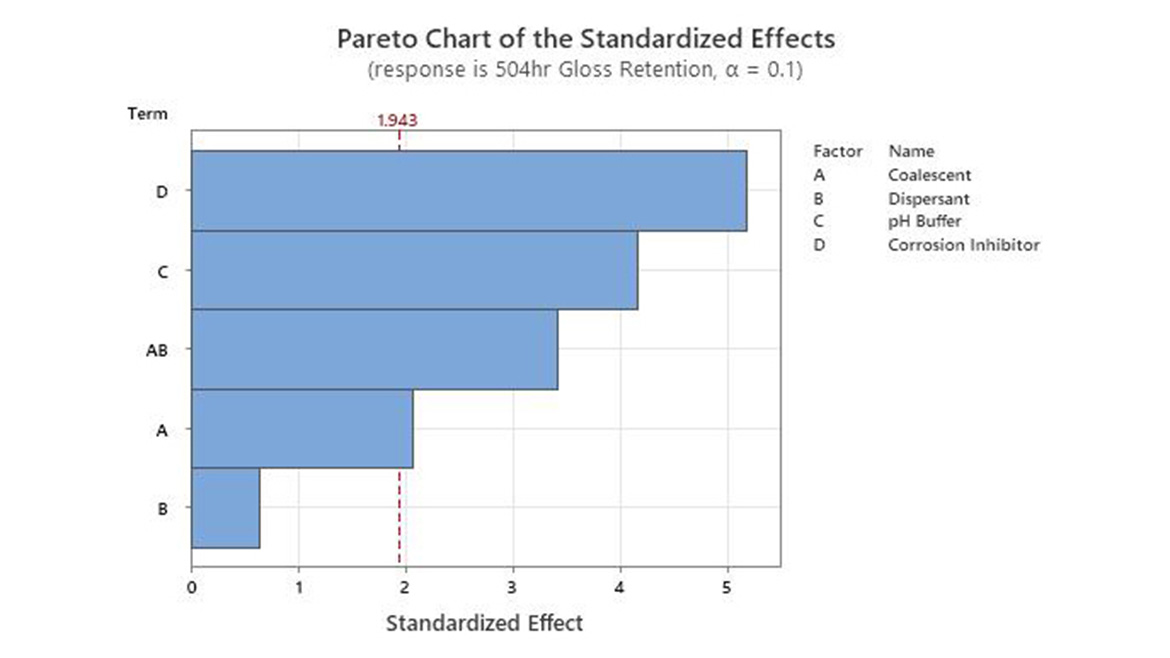

The Pareto chart in Figure 7 identifies corrosion inhibitor and pH buffer as the key influencing factors.

In this four-factor fractional DOE, the two-way interaction of coalescent agent/dispersant (AB) is confounded with the pH buffer/corrosion inhibitor (CD). As shown in Table 4, the interaction between corrosion inhibitor and pH buffer directly influences gloss retention.

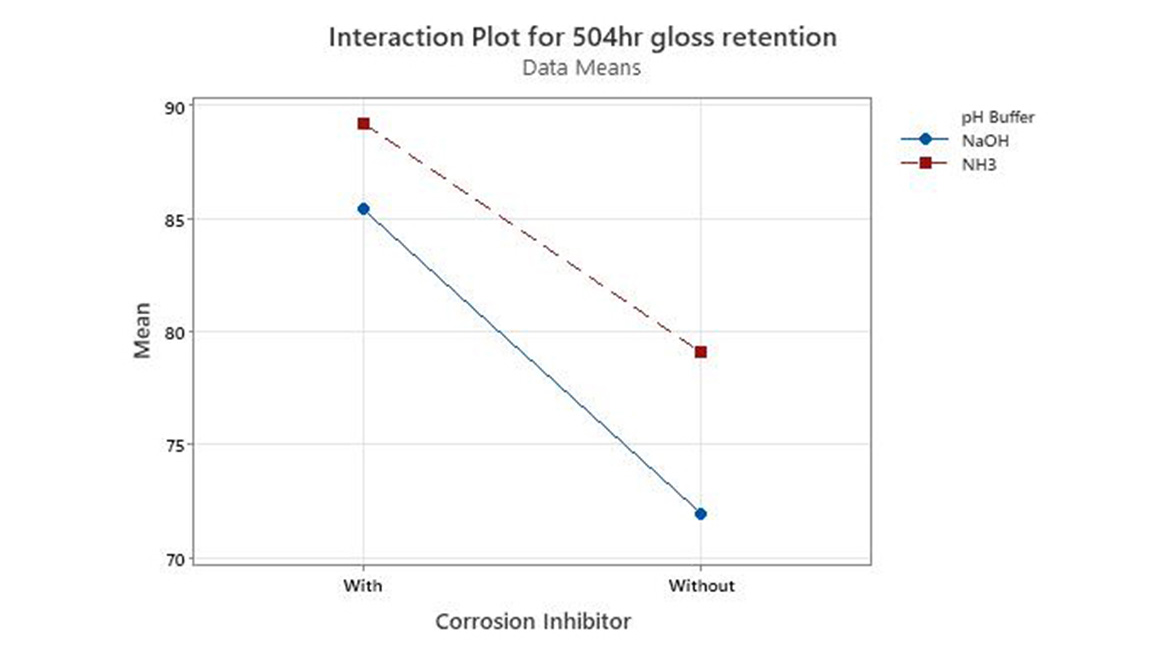

Samples that achieved gloss retention above 80% incorporated corrosion inhibitors in the formulation. Figure 8 presents the interaction plot for pH buffer type and corrosion inhibitor use, showing a modest interaction effect. Using the corrosion inhibitor helped maintain gloss, and when formulated with ammonia, gloss retention was further enhanced. The nonvolatile buffer led to lower gloss retention, potentially due to residual solids remaining in the cured film.

Electrical Impedance Spectroscopy

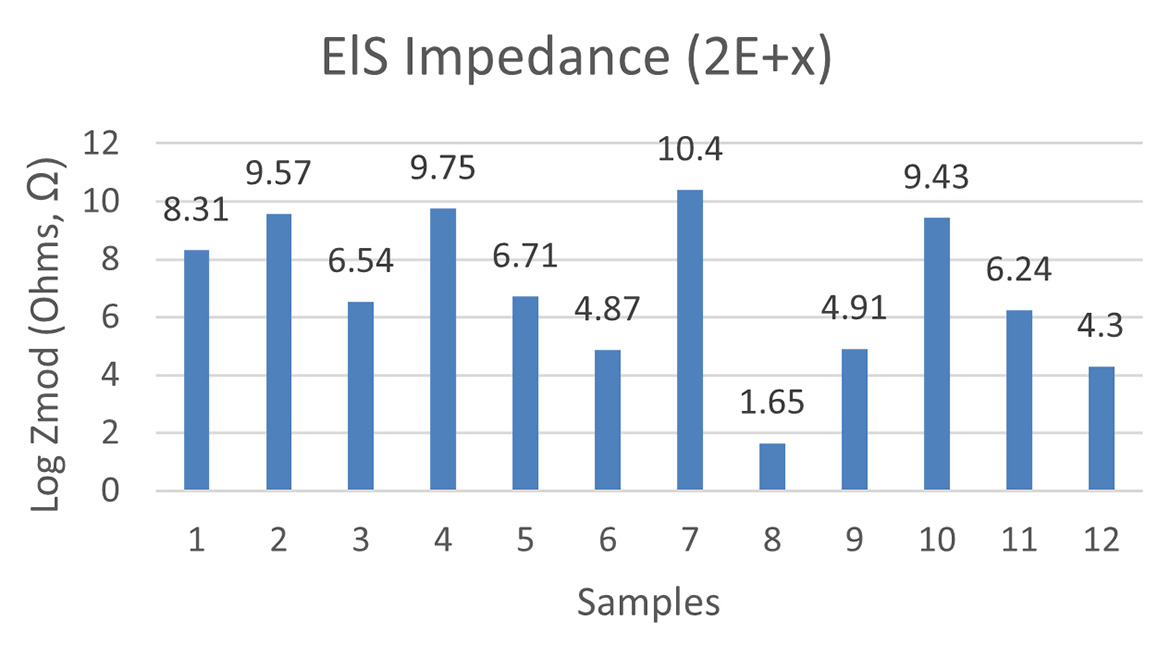

The electrical impedance spectroscopy (EIS) measurements and the log of the lowest frequency Zmod value are shown in Figure 9. The impedance is the resistance of the coating to incoming electrolytes and ions, which results in a corrosive environment. Higher impedance values (ohms) suggest better protective barrier properties. When the impedance value is high, for example greater than 109 ohms, the coating can better resist an electrical current. By inhibiting the transfer of electrons, the pathway for corrosion is slowed down.

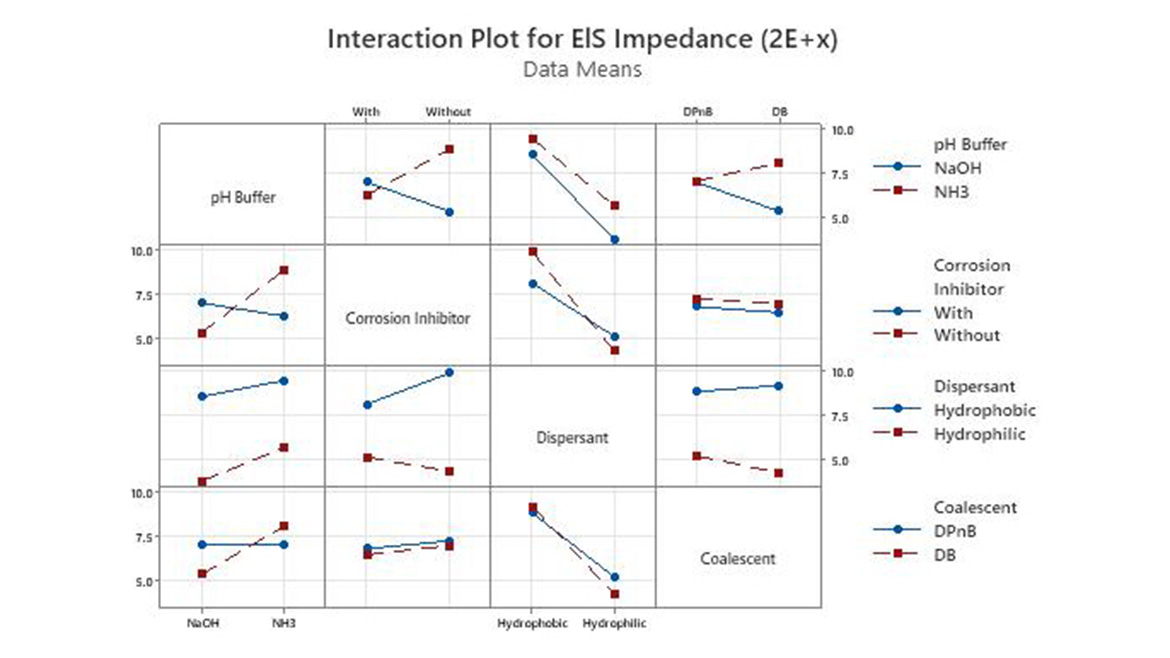

The Pareto chart in Figure 10 shows that impedance performance is strongly influenced by the type of dispersant. The top performers for EIS measurements — samples 2, 4, 7 and 10 — have the highest values, all of which contained the hydrophobic dispersants. The full interaction plot is shown in Figure 11.

From the Pareto chart, the largest driver of high impedance is the use of a hydrophobic dispersant. However, by looking at all the interactions between the factors, utilizing a corrosion inhibitor with a volatile buffer (NH3) will increase the impedance as well.

Summary

Styrenated acrylic DTM emulsions are engineered to deliver excellent adhesion and corrosion performance while maintaining a low-VOC demand of less than 100 g/L. This study investigated various formulation factors to understand their impact on specific performance attributes. Depending on the intended use of the DTM application, formulators can tailor the formulation to enhance particular performance characteristics. The emulsion is suitable for direct-to-metal applications, and with appropriate formulation adjustments, can be optimized for final property performance. The main conclusions from this study can be summarized below:

- The polymer can achieve 100% film adhesion (5B wet and dry) within 7 days of curing. However, studying the DTM formulations with 1-day wet adhesion performance was more meaningful. The coalescing agent DPnB, an immiscible solvent, was preferred for producing the highest wet adhesion after 1 day.

- To minimize rust scribe development, this study suggests using a volatile pH buffer that does not remain in the coating. Additionally, incorporating a corrosion inhibitor can decrease creepage. However, formulations without a corrosion inhibitor also exhibited low scribe creep.

- The color change in the samples was too minimal to distinguish effects, indicating that the resin is robust and various additive changes do not significantly influence color.

- A combination of a volatile pH buffer and a corrosion inhibitor resulted in the highest gloss retention.

- Impedance measurements were maximized when a hydrophobic dispersant was used. Further exploration revealed interactions between the corrosion inhibitor and a volatile buffer. Ammonia showed a significant performance increase compared to using a nonvolatile buffer like NaOH.

Overall, high-performance direct-to-metal coatings can be developed by utilizing appropriate resin, and by selecting additives that allows one to tailor DTM formulas to emphasize specific attributes for their intended applications.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!