Evolution of the Coatings Industry

A Shift Toward Sustainability

pcess609 / iStock via Getty Images Plus

In today's world, sustainability has become a crucial aspect of every industry, and the paint and coatings sector is no exception. Senior executives navigating this landscape must understand the multifaceted role of sustainability within their operations. This concept extends beyond merely being environmentally friendly; it includes the efficient use of resources, waste reduction and developing high-performing products with minimal environmental impact. As industries increasingly shift toward innovative solutions such as powder coatings, bio-based coatings and other green alternatives, these options offer eco-friendly features, enhanced performance measures, cost savings and compliance with regulations. Such a strategic shift leads to strong business returns and long-term success. In exploring sustainability in the paint and coatings industry, we will delve into these pioneering changes that promise a better future while maintaining product quality and performance.

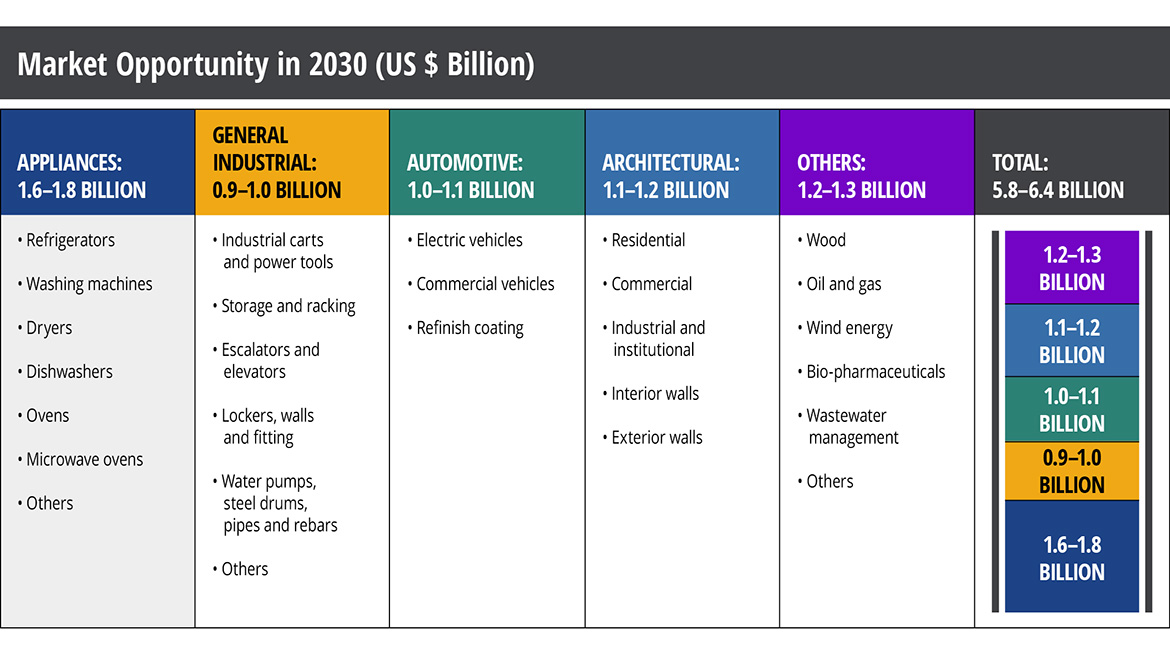

Source: Secondary research, interviews with experts and MarketsandMarkets Analysis. Other coatings include radiation curable, thermal spray, high solids, etc.

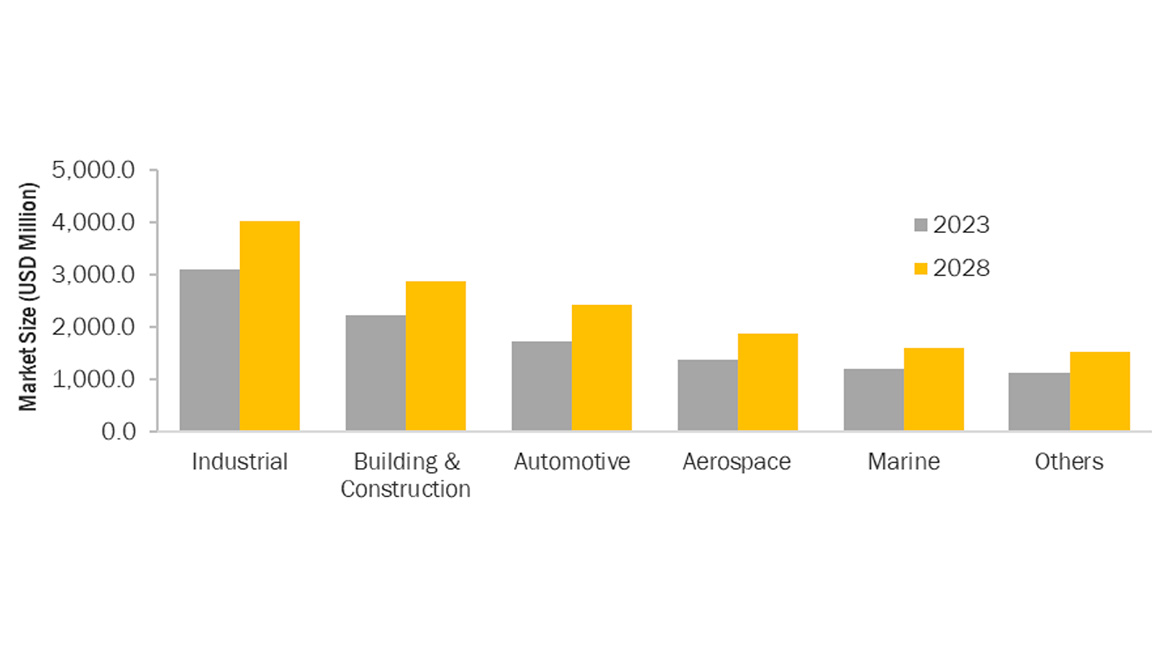

The coatings industry has seen significant advancements driven by continuous innovations in applied technologies and emerging trends. Solventborne coatings, which have traditionally dominated the market, are gradually being phased out due to stricter regulations on VOC emissions and the availability of more sustainable, low-VOC alternatives. The market for low-VOC coatings is expanding as environmental concerns and consumer demand for healthier, more efficient products increase. As awareness of the harmful effects of VOCs on health and the environment grows, consumers and industries are actively seeking coatings that reduce these risks while maintaining durability and aesthetic appeal.

After conducting thorough research, we have pinpointed several pivotal technologies and emerging trends that we believe can significantly influence the future of the paint and coatings industry. In the following sections, we will dive deeper into these insights, highlighting how these innovations can enhance product performance and meet the evolving demands of consumers. By staying ahead of these trends, executives can strengthen their market position and drive sustainable growth.

Powder Coatings: A Game-Changer in Sustainable Coatings

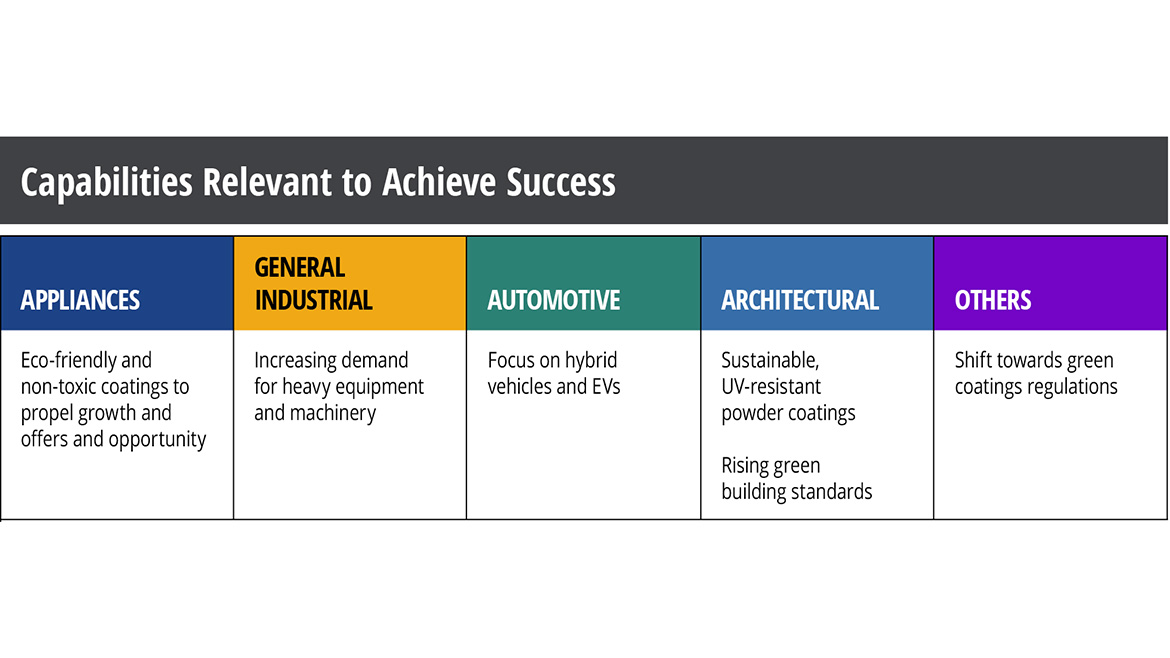

Powder coatings are rapidly emerging as a key player in the sustainable coatings market, primarily due to their eco-friendly properties and superior performance compared to traditional liquid paints. This growth is fueled by increasing demand for durable and environmentally friendly solutions across various sectors, including automotive, appliances and architecture. Regulatory pressures emphasizing low-VOC emissions further enhance the appeal of powder coatings as a compliant choice.

With their low- or zero-VOC content, powder coatings align with the industry's shift toward sustainability. They offer a solvent-free application process that minimizes environmental impact. Powder coatings' robust and resilient finishes exceed global sustainability standards, making them a preferred option for industries aiming to reduce their carbon footprint while maintaining high-quality performance.

The automotive industry favors durable powder coatings for wheels and body parts, highlighting their cost effectiveness and long-term benefits. Powder coatings are also essential in the electric vehicle (EV) sector, providing eco-friendly and durable solutions for components such as battery enclosures, electric motors and lightweight structural parts. These coatings offer excellent corrosion resistance, heat management and electrical insulation, enhancing EV systems' performance, longevity and safety while supporting sustainability goals through low-VOC and energy-efficient application processes.

Companies such as AkzoNobel, PPG Industries and Axalta Coating Systems are investing in advanced powder coating solutions that improve performance, reduce energy consumption and provide enhanced protective properties. Ongoing technological advancements, including the development of self-healing smart coatings, promise future benefits such as extended durability and reduced maintenance requirements.

Global trends indicate continued adoption of sustainable powder coating solutions across various industries, driven by their ability to significantly reduce environmental impact while maintaining high performance and durability.

Bio-Based Coatings: Merging Performance with Sustainability

Bio-based coatings are gaining popularity as they reduce reliance on fossil fuels and lower the carbon footprint. These coatings utilize materials such as vegetable oils, plant-derived fractions and natural pigments in their resins, solvents, pigments, or additives. Compared to traditional petrochemical options, this shift can decrease greenhouse gas and VOC emissions by about 50%, contributing to the fight against climate change.

The market for bio-based coatings is experiencing strong growth, driven by increasing consumer awareness, sustainability priorities and stricter regulations. While the construction and building sectors are the primary applications, the transportation and woodworking industries are also expanding due to technological advancements and government incentives.

Despite their advantages, bio-based coatings currently account for only a small portion of the global market — less than 5%, and up to 10% when including products with minimal bio-based content. High costs, limited availability of bio-based feedstocks and complex production processes hinder their competitiveness against traditional options. Furthermore, technological challenges, such as raw material costs and reduced funding for research, impede market growth.

Consumer hesitance also restricts wider acceptance, as concerns about product performance and reliability can deter shifts toward bio-based alternatives. In response, major paint manufacturers like PPG, Sherwin-Williams and AkzoNobel are investing in research and development of bio-based and green alternatives to establish market leadership in this evolving sector.

Integrating bio-based raw materials enhances resource sustainability and fosters eco-friendly solutions. As awareness of the benefits of bio-based coatings rises, these products are expected to gain a larger market share, meeting consumer demand and supporting a more environmentally conscious industrial ecosystem. With the increasing demand for sustainable products, bio-based coatings are poised to significantly influence the future of the coatings industry.

Enhancing Energy Efficiency by Reflecting Heat or Insulating Surfaces

Advancements such as cool roof coatings — reflective coatings designed to have high levels of heat emittance and solar reflection — have significantly improved energy efficiency in the paint and coatings industry. These reflective coatings are particularly effective in hot climates, as they can reduce energy costs by up to 30% when applied to roofs and exteriors.

In contrast, insulating paints utilize innovative materials like aerogels or ceramic microspheres to create a heat barrier. By reducing heat transfer, these coatings function as insulators, helping to maintain consistent temperatures in pipes, storage tanks, and external walls for commercial, industrial and residential applications. Both reflective and insulating coatings offer a sustainable approach to energy savings, minimizing the carbon footprint while enhancing thermal comfort.

The insulation coatings market is experiencing considerable growth, primarily driven by increasing demand for heat, electricity and sound insulation across various industries. As businesses focus on energy efficiency, thermal insulation coatings have become essential for reducing heat transfer and conserving energy. Industries such as construction, automotive and manufacturing are adopting insulation coatings to improve building insulation, decrease energy consumption and enhance overall process efficiency.

The EV production surge has created a demand for insulation coatings in battery systems and other critical components. With governments worldwide promoting EV adoption through various incentives and initiatives, market players in the insulation coatings industry are expected to witness new opportunities. The rising focus on sustainable transportation and energy-efficient solutions further strengthens the prospects for insulation coatings in the EV sector.

Enhancing Surface Durability with Advanced Coatings

Self-cleaning, anticorrosion and antimicrobial coatings represent a significant advancement in surface technology. They greatly improve durability and reduce maintenance needs. These coatings protect surfaces from environmental contaminants and microbial growth, ensuring they remain functional and visually appealing for longer periods.

For example, self-cleaning coatings employ hydrophobic or photocatalytic properties to repel dirt and grime. This minimizes the need for frequent cleaning and decreases the use of water and chemicals, ultimately cutting costs and supporting sustainability efforts by conserving resources.

Anticorrosion coatings are crucial in various industries, including construction, automotive and marine, where materials are exposed to harsh environments. These coatings prevent the deterioration of metals and other materials caused by moisture, salt and chemicals, effectively extending the lifespan of infrastructure and equipment. By reducing the necessity for repairs or replacements, anticorrosion solutions minimize material waste and lower the carbon footprint associated with manufacturing and transporting new parts.

Antimicrobial coatings serve a dual purpose by enhancing surface performance and promoting health and safety. By inhibiting the growth of harmful microorganisms, these coatings are essential in healthcare, food processing and public spaces. In addition to their immediate health benefits, antimicrobial surfaces reduce the frequency of disinfectant use, leading to lower chemical emissions and less waste generation. These coatings enable industries to adopt more environmentally friendly practices while delivering superior functionality and long-term cost savings.

Conclusion

The shift toward low-VOC and sustainable coatings presents a significant opportunity for the coatings industry to align with global sustainability goals. As companies continue to innovate and invest in environmentally friendly alternatives, they are well-positioned to capture new market segments and enhance their competitive edge. With sustainability becoming a core business strategy, the future of coatings will likely be dominated by solutions that deliver environmental benefits and high performance.

For more information, contact the author.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!