The Coatings Strategy Behind Safer, Longer-Lasting Infrastructure

Understanding Protective Coatings

In today’s world, protective coatings are silently at work — on bridges, buildings, pipelines, aircraft, ships, and even on kitchen appliances. They play a crucial role in preserving the integrity, appearance, and longevity of materials exposed to environmental stressors. Essentially, a protective coating is a layer of material applied to a surface to prevent or mitigate corrosion, wear, and degradation caused by exposure to moisture, chemicals, UV radiation, or mechanical stress.

These coatings come in various forms — paints, powder coatings, varnishes, and films—each formulated for specific applications. Their purpose isn’t merely aesthetic; while they may enhance the look of a structure or product, their real strength lies in their ability to prolong the life of the underlying material.

The global protective coatings market was valued at $30.2 billion in 2024 and is projected to reach $46.5 billion by 2033, expanding at a compound annual growth rate of 6.3%, according to Persistence Market Research. These coatings, primarily composed of epoxy, alkyd, acrylic, or polyurethane, are essential for preserving surfaces in industries like oil and gas, maritime, and construction. Widely used in civil engineering for infrastructure protection, their demand is driven by increased machinery use, rising infrastructure investments, and the expansion of renewable energy facilities where durability under harsh conditions is vital.

Types of Protective Coatings and Their Applications

Protective coatings can be broadly categorized based on their composition and function. Common types include:

- Epoxy coatings: Highly resistant to corrosion and chemicals, making them ideal for industrial applications and marine environments.

- Polyurethane coatings: Valued for their flexibility and UV resistance, often used in automotive and aerospace industries.

- Zinc-rich primers: Provide cathodic protection to steel structures by acting as a sacrificial layer.

- Ceramic coatings: Known for heat resistance and durability, widely used in high-temperature applications like engines and turbines.

Each type is tailored to combat specific threats. For example, offshore oil rigs use heavy-duty epoxy systems that withstand saltwater corrosion, while pipelines might be coated with fusion-bonded epoxy (FBE) to resist soil chemicals and abrasion.

The Science Behind the Shield

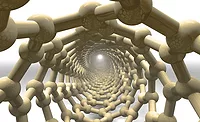

The efficacy of a protective coating lies in its ability to form a continuous, impermeable barrier between the material and the external environment. Some coatings work by repelling moisture or chemicals, while others contain inhibitors that actively prevent corrosion. In certain advanced formulations, nanotechnology is used to enhance adhesion, self-healing properties, and resistance to microscopic wear.

Surface preparation is critical. A poorly prepped surface can lead to premature failure, regardless of how advanced the coating might be. Techniques like sandblasting, power washing, and chemical cleaning ensure optimal adhesion and performance.

Industries That Rely on Protective Coatings

From aerospace to architecture, protective coatings are a backbone of modern infrastructure:

- Oil and gas: Coatings protect pipelines, rigs, and storage tanks from corrosive chemicals and environmental extremes.

- Marine: Ships and offshore platforms need coatings that resist saltwater, biofouling, and UV exposure.

- Construction: Steel frameworks, bridges, and concrete surfaces are protected against rust, moisture, and pollution.

- Automotive and aerospace: Coatings improve fuel efficiency, reduce maintenance costs, and enhance the appearance and lifespan of vehicles.

Even the food and pharmaceutical industries rely on coatings to create sterile and easy-to-clean surfaces in production environments.

Economic and Environmental Benefits

While the upfront cost of protective coatings can seem high, the long-term savings are substantial. By preventing corrosion and degradation, coatings reduce the need for repairs, replacements, and downtime. For example, a well-coated bridge can function safely for decades without significant maintenance.

There’s also an environmental upside. Preventing rust and decay reduces material waste and resource consumption. Newer coating technologies focus on eco-friendly formulations—low-VOC (volatile organic compounds) paints, waterborne coatings, and bio-based resins that lessen environmental impact without compromising performance.

Innovations Driving the Future of Protective Coatings

The protective coatings industry is evolving rapidly, with advancements focusing on performance, sustainability, and smart functionality. Some key trends include:

- Self-healing coatings: These use microcapsules or chemical reactions that activate when damaged, automatically sealing small cracks or scratches.

- Antimicrobial coatings: Crucial in hospitals and food facilities, they inhibit the growth of bacteria and mold.

- Smart coatings: Embedded with sensors or responsive elements, these coatings can change color in response to damage or environmental changes, acting as early warning systems.

Research is also pushing the boundaries of sustainability, with developments in biodegradable coatings and those derived from natural polymers.

Challenges in the Coating Industry

Despite the many benefits, protective coatings face challenges. One is durability in extreme environments—like deep-sea or high-temperature settings. There’s also the issue of compatibility between different layers (e.g., primer, topcoat) and the substrate. Misalignment can cause peeling, cracking, or bubbling.

Additionally, regulatory pressures are growing. Coating manufacturers must navigate increasingly stringent health, safety, and environmental regulations, which drive innovation but also increase development costs.

Maintenance and Inspection: Keeping the Coatings Working

Application isn’t a one-time solution. Maintenance and regular inspections are essential to ensure long-term performance. Many industries use non-destructive testing methods—like ultrasound, X-ray, or infrared scanning—to check for hidden issues without damaging the coating or the material underneath.

Some facilities implement coating maintenance schedules aligned with predictive maintenance systems. This proactive approach helps address potential failures before they become serious, saving both money and lives.

More Than Just a Pretty Surface

Protective coatings may not always be visible, but they are an essential line of defense in almost every modern industry. They preserve structural integrity, reduce environmental impact, and offer significant economic benefits. As technology continues to advance, these coatings will only become more intelligent, durable, and sustainable.

Whether it’s the sleek paint on a sports car or the invisible layer safeguarding an underwater pipeline, protective coatings are a testament to engineering innovation—and to the enduring effort to protect what we build.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!