Protecting the Future

Nycote has a range of coatings that have been used for decades in the aerospace industry with well-mapped, high-performance characteristics that provide a basis for the future. By using this proven, highly adhesive, and durable technology as a medium to carry additional materials, the company is addressing specific needs arising from new challenges of the 21st century.

Established products Nycote 7-11 and 88 have similar performance levels. Nycote 99 is an update of 7-11 with a more compliant solvent content. All three products are based on a nylon-epoxy hybrid and can be described together in similar terms. The products are typically applied in a thin film of 10-20 microns dft and reach full performance level at that thickness. The coatings are transparent and adhere well to a wide range of substrates, including metals, plastics, rubbers, and composites; in addition to a variety of surface treatments and other coatings. Aircraft typically operate at temperatures between -55 °C and 125 °C, and their components need to resist corrosion and attack by a range of chemicals including fuel, hydraulic fluid, deicers, and water (Table 1).

Coatings need to protect these substrates for decades, while allowing reliable operation of the aircraft, whether a fast jet fighter used at extreme angles for a few hundred hours per year, to a wide-body intercontinental jet flying for 4,000 hours per year at high altitudes.

Nycote’s products are free of current SVHCS under REACH, and have few fillers and pigments. The company has decided to use basic product chemistry as a vehicle to deliver additional performance features that can be carried by the basic highly durable coating. Some of these require significant additions and some are minor modifications followed by qualification testing to ensure the new performance features are functioning.

Anti-Viral Coatings

The global pandemic heightened awareness of disease transmission by contact with viruses and other bugs from sites such as high-touch surfaces. In the aerospace sector this is a well-known scenario with illnesses such as Norwalk, Avian Flu, food poisoning, and others that need to be controlled in the confines of a passenger cabin.

The coating is a thin, transparent film that is extremely difficult to remove and is resistant to cleaning fluids. It represents an ideal medium to hold an anti-viral effect that remains effective for as long as the coating is in place. The basic formula has already been used successfully against fungal growth and as an anti-fungal coating. The company researched many candidates for an anti-viral compound before selecting a zinc-based additive. This is the basis of Nysafe AV-900. The anti-viral additive is presented in a separate pack that helps to maintain the shelf life of the product before use.

The company has invested in testing the new product to ISO22196 for bacteria and ISO21702 for viruses (Table 2).

The coating provides permanent protection from damage and corrosion, as well as a powerful anti-viral effect. The principal end use is as a coating for passenger accommodation such as aircraft cabins. The product must also meet the flammability requirements of the CAA/JAA 25.853 testing, which includes burn length, smoke density, toxic gas emission, and heat release. Nysafe fully meets these standards and it may be possible to extend its use to non-aerospace transportation equipment such as trains and ships considering the flammability requirements of those markets.

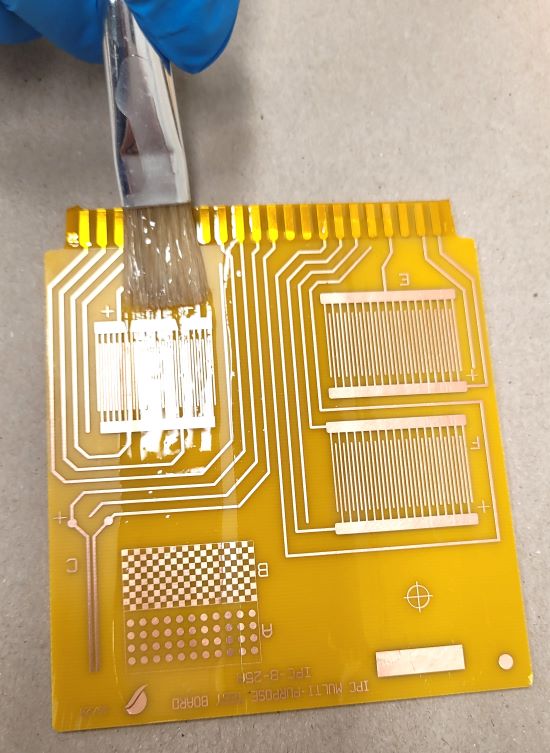

Conformal Coatings

The goal of these products is to perform as a very-effective encapsulant, preventing the ingress of corrosive media and thus extending the use of this technology to applications where this is a basic requirement. The company recognized that conformal coatings used for electronics such as PCBs form an important market. The key requirements are a thin, closed film that is completely insulative, resistant to ingress and electrical current in order to avoid flashover. For this application the modifications required are very few, including a slight reduction in viscosity to encourage penetration around complex shapes, and the addition of a fluorescent trace to allow the application to be checked by inspection with a UV light. These changes result in Nyform, an effective, conformal coating for electronics and PCBs.

The products have a 60-year track record of durability, used on high-value electronics such as those in aerospace where it is critical that they do not fail over very-long service periods in difficult environments. An important performance specification for conformal coatings is IPC-CC-830, with which the product complies (Table 3).

Traceability Coating

Having a thin film coating that is very durable and difficult to remove allows for the application of security features to high-value equipment. Using its existing coatings technology as a basis, Nycote has suspended a machine-readable optical fingerprint within the coating. Each fingerprint is unique, which makes it possible to identify whether a component is genuine or counterfeit, and also to attribute specific data to the component, such as batch numbers, production locations, or any other information. The unique optical reflection of each fingerprint is combined with the scatter pattern of the particles, to create a digital twin of any component and to record any information required. This feature helps with anti-counterfeit applications and is a solution to digital product passports, as it is practically impossible to remove the tracer coating and only a small amount is required to provide a reading.

The coating can be applied specifically for this purpose, or as a protective coating in the normal production routine, as a conformal coating, or a lacquer over standard part markings. There is little or no extra cost of the process.

Use in Space

As we look to the future it is clear that mankind will be increasingly exploring and exploiting space. Features such as electrical protection, anti-viral action, and traceability are all applicable, as well as general protective coatings to preserve sensitive components against environmental impacts.

When placed in a vacuum (as in space), polymeric materials lose mass due to sublimation or “outgassing. This mass loss has two main negative impacts:

- It alters the performance of the polymer as a result of the loss of part of its composition to evaporation.

- The lost mass can be deposited on other parts of the surroundings, such as optical equipment and other critical components, which can detract from their performance.

To evaluate the outgassing of coatings, mass loss can be determined through measuring the mass lost in a vacuum at elevated temperature. The two critical measures for space application are:

- RML (Recovered Mass Loss): Mass loss after water absorption during post-conditioning (relative to initial sample mass). The result should be <1%.

- CVCM (Collected Volatile Condensable Material): mass gain of collectors relative to initial sample mass. The result should be <0.1%.

Both ESA and NASA have similar test requirements and the products have been tested and conform to these limits. This ensures that the conformal coating, anti-viral coating, and traceable coating can all be used in space environments.

The company believes that a strong, proven technology base with a long history of service provides a great platform to leap into the future with new technologies. Using its existing coatings as a vehicle for future developments, it is working with several technology leaders who need a platform to deliver its tech onto surfaces in the real world, and welcomes partnerships with innovators who need a reliable coating to carry their performance enhancing materials.

*Images courtesy of Nycote.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!