Sustainability Advances Shaping Coatings Research and Manufacturing

Monthly spotlight centered on a key industry topic.

In this article:

- Fluorinated Material Recovery Advances

- Sustainable Manufacturing Strategies

- Remanufacturing for Lower Impact

- Industry Circularity Developments

- Research Driving Sustainability

This issue features two perspectives on sustainability. The first is a research-focused contribution from Professor Norio Shibata and colleagues at Nagoya Institute of Technology on room-temperature defluorination and fluorine recovery from PTFE and PFAS. The second is a manufacturing study from Missouri University of Science and Technology by Dr. Joshua Adu Afari and collaborators, published in Springer Nature, that evaluates remanufacturing efficiency and its implications for cost, waste reduction and carbon impact. Together, these pieces explore sustainability from both a materials and operational standpoint.

Room-Temperature Defluorination Achieves High Fluorine Recovery

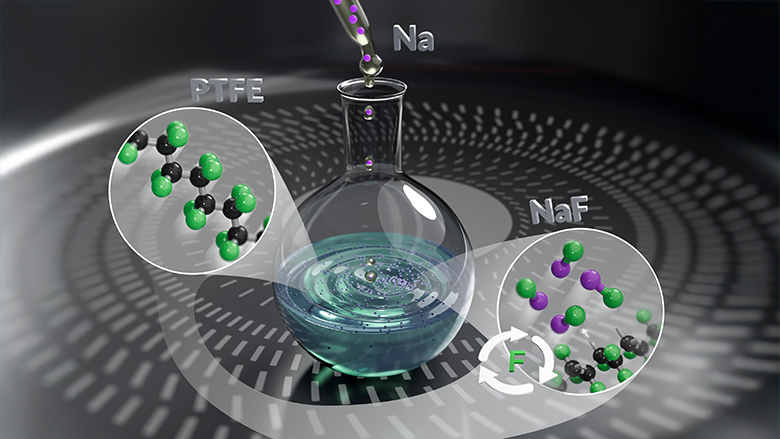

Researchers have demonstrated a room-temperature method for defluorinating and recovering fluorine from PTFE and PFAS under mild conditions. Traditional defluorination approaches often require temperatures above 500 °C or involve complex chemistries, creating both environmental and operational challenges for recycling fluorinated materials. The new method, developed by an international research team led by Professor Norio Shibata of Nagoya Institute of Technology, enables high-yield fluorine recovery using sodium dispersion as the reactive medium.

PTFE is widely used in applications such as non-stick coatings and electrical and optical fiber cable insulation due to its thermal stability and low friction. However, its persistence creates significant disposal concerns. Incineration requires high energy and can release hydrogen fluoride, while landfilling leaves PTFE intact in the environment. Defluorination offers an alternative by converting the polymer into recoverable fluorine compounds, yet earlier methods have faced limitations related to efficiency and reaction conditions.

In this study, sodium dispersion in tetrahydrofuran at 25 °C achieved fluoride ion yields up to 98% from PTFE within a 12-hour reaction period. Spectral and morphological analyses confirmed both fluorine recovery and changes to the surface structure of the resulting residue. The team also applied the method to several PFAS compounds, including perfluorononanoic acid, perfluorooctanoic acid, perfluorobutanesulfonic acid and trifluoroacetic acid, and reported fluorine recovery rates up to 97% with adjusted reaction parameters.

According to the researchers, the method’s room-temperature performance offers advantages over plasma processing or high-temperature incineration and supports expanded pathways for fluorine recycling. The approach may help reduce environmental impacts linked to fluorinated materials and provide a foundation for more sustainable fluorine resource utilization.

Linking Material Circularity to Smarter Production Systems

While advances in fluoropolymer recycling address material sustainability, the transition to more sustainable production systems also depends on improvements in manufacturing efficiency. Recent research in remanufacturing illustrates how facility-level decision making can reduce waste, energy use and overall production costs while extending product life cycles.

Remanufacturing Model Supports More Efficient Manufacturing

A study from Missouri University of Science and Technology explores a new modeling approach that may help manufacturers reduce costs and limit carbon emissions through optimized remanufacturing practices. The research, published in Springer Nature, was conducted by Dr. Joshua Adu Afari with contributions from Dr. Abhijit Gosavi and Dr. Robert Marley and supported by a National Science Foundation grant.

The study focuses on remanufacturing, a process in which used machinery components and other products are restored for repeated use. Afari examined an existing model and modified it to maintain the original dimensions of the production area, which lowers material handling requirements. He notes that reducing these handling costs directly influences total production costs and provides economic benefits for both manufacturers and consumers.

The research highlights the importance of advanced manufacturing for local and national production capacity. Marley observes that remanufacturing can help reinforce regional manufacturing by reducing the need for new facilities and making ongoing operations more practical in areas where start-up costs may otherwise be restrictive. Gosavi adds that modeling offers a controlled pathway for testing improvements before implementation, allowing engineers to refine processes without interrupting existing production.

The authors also discuss broader implications for the United States, noting that traditional linear production patterns often result in products being scrapped or exported for processing. A more circular framework, in which remanufacturing is integrated into standard production cycles, could improve resource efficiency and reduce waste. Afari states that the goal is to support manufacturing systems that save time, minimize waste and strengthen environmental performance while meeting product needs.

For readers who want to review the full study, the Springer Nature article is available at: https://link.springer.com/article/10.1007/s12008-025-02296-5

Integrating Research and Operations for Long-Term Sustainability

Sustainability in the coatings sector continues to evolve through material innovation and improved production methods. Whether through advances in fluorine recovery that support responsible handling of fluorinated materials or through remanufacturing strategies that reduce waste and energy consumption, these developments show how scientific research and operational modeling contribute to a more efficient and environmentally responsible industry. As new technologies and practices emerge, integrating these approaches across raw materials, manufacturing and lifecycle management will remain essential for long-term progress.

Learn more about sustainability trends shaping coatings at PCI’s Sustainability topic page.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!