Understanding Fire Testing Practices for Cellulosic Passive Fire Protection Systems

A Critical Component of Structural Safety

- Fire testing verifies how cellulosic passive fire protection coatings perform under realistic structural loads and temperature conditions.

- Accurate testing data supports correct dry film thickness selection for different steel sections and assemblies.

- Compliance with global fire standards helps ensure evacuation time, structural stability and long-term asset protection.

Structural steel is an essential building component in modern architecture, prized for not only its strength but also its design flexibility. Steel supports nearly every type of commercial and manufacturing infrastructure project today, from office buildings to airports to manufacturing facilities. According to the World Steel Association, the buildings and infrastructure sector utilizes over half of all steel produced worldwide.1

Although steel has exceptional load-bearing capabilities, it is vulnerable to environmental stressors. Prolonged exposure to moisture and harsh environmental conditions can cause corrosion, leading to loss of steel and pitting that compromises structural integrity.

In infrastructure applications, cellulosic fires, those fueled by flammable domestic materials such as wood, furniture and textiles, also put structural steel at risk. When fires occur, steel typically loses approximately 50% of its strength when its temperature reaches 1,100 °F (593 °C),2 depending on the applied loads. Fire protection systems, which can be active or passive, are designed to protect structures and building occupants from damage caused by structural failure.

Passive fire protection (PFP) coatings are applied to structural steel to insulate the structure from the high temperatures of fire and play an important role in protecting infrastructure assets from corrosion by:

- Increasing critical time for safe evacuation of building occupants

- Helping to protect the building from structural failure

There are several types of PFP solutions available for cellulosic fires, including intumescent coatings, cement sprays and fire boards.

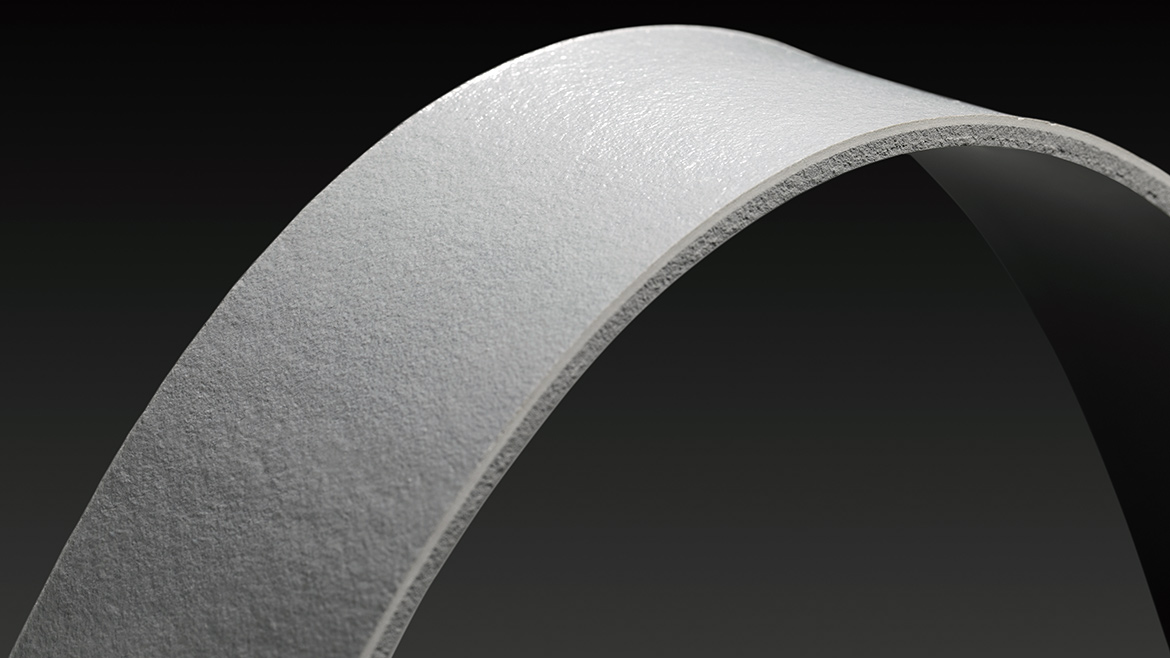

Intumescent PFP coatings, such as the PPG STEELGUARD® product range, are reactive protection materials that are activated by heat. When exposed to high temperatures, these coatings expand and create a char that protects and insulates the exposed steelwork. The insulating char extends the time to the calculated failure temperature, preserving the structural integrity of the steel. As opposed to other types of PFP solutions, intumescent coatings offer a smooth and versatile finish that can accommodate the aesthetic requirements of architecturally exposed structural steel (AESS).3

Intumescent coatings are typically formulated with an organic binder, an acid catalyst, a carbonific and a blowing agent. Starting at around 400 °F (200 °C), the acid catalyst and carbonific combine to form an ester, which works with the blowing agent to create an insulating foam that can expand up to 50 times the applied dry film thickness (DFT).

The Importance of Fire Testing

An effective, properly installed PFP system insulates steel from the extreme heat of fires to maintain stability, adding valuable time for occupants to evacuate and can mitigate potential structural damage. However, the successful performance of these coatings is dependent on a variety of factors, including proper surface preparation, mixing, application method, coating thickness and the use of approved primers and topcoats.

If a fire protection coating fails in a high-occupancy structure, the consequences can be catastrophic. On unprotected steel, the high temperatures can quickly cause beam deflection, which destroys compartmentation and allows fires to spread throughout the building faster. Column buckling can result in building collapse and the loss of escape routes, which are dangerous situations for building occupants trying to evacuate and firefighters working to control the fire. In addition, major structural failures often result in extensive damage and rebuilding costs.

Accurate fire testing and documentation protocols are crucial for the correct application of PFP coatings. It is essential to test the performance of coating systems to ensure they will perform as required, providing the insulation to protect steel for the required length of time specified by the relevant building code.

All manufacturers must accurately represent the performance capabilities of products to consumers.

Manufacturers should have the responsibility to ensure that products are designed, produced and utilized in a way that ensures the product performs as intended.

Particularly in the case of PFP coatings, in which malfunctioning products could put lives at risk, verifiable and reproducible test results are paramount. Conducting in-house testing, obtaining third-party certifications and rechecking demonstrate a commitment to minimize risks through safe design and compliance with regulations.

With a variety of intumescent PFP coating systems available on the market, different fire testing standards and organizations, and required compliance with local building codes, selecting the right coating can be challenging. This paper aims to explain fire testing standards for cellulosic PFP coatings and assert the importance of choosing a coatings supplier invested in thorough testing practices and transparent communication.

Evolving Fire Regulations

The regulatory landscape of PFP systems is complex due to differing global standard development and the continued evolution of building codes. There are many recognized test standards nationally and internationally designed by different organizations, such as UL Solutions and ASTM International. The UL 263 and ASTM E119 standards are used to evaluate fire protection coatings for structural steel.

Each fire testing standard is accepted in specific locations. In the Middle East, for example, many building codes reference National Fire Protection Association (NFPA) standards. Each country defines its own building codes, however, and many codes are designed and enforced by government ministries or Authorities Having Jurisdiction (AHJs). The International Code Council Middle East and North Africa (ICC MENA) is working toward regulatory alignment in the region with internationally recognized test standards.

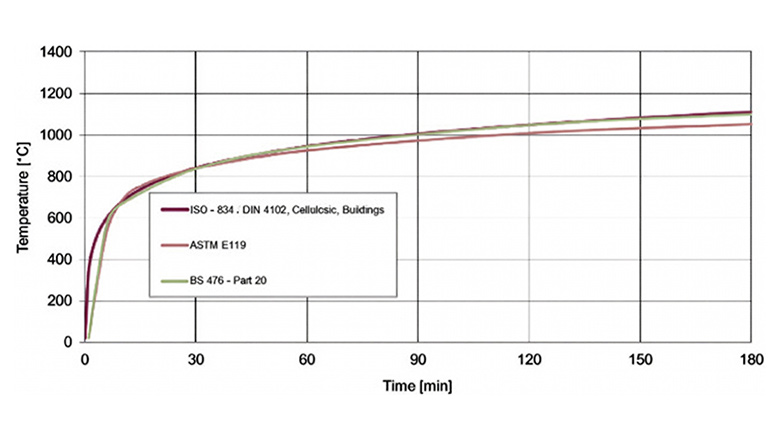

For cellulosic fires, testing standards follow the cellulosic fire curve (also referred to as the standard fire curve), which is meant to represent the rate of temperature increase in fires using cellulose-based materials such as paper and wood as fuel. This time and temperature curve features a more gradual rise in temperature than hydrocarbon fires, in which flammable liquids such as oil and gas raise temperatures extremely quickly.

For most standards, fire testing must be conducted at third-party labs that adhere to the procedures outlined by the organization. It is important that testing laboratories have their own calibration standards to ensure their equipment can achieve the necessary furnace temperatures and loads defined in the applicable test standard.

However, there is no governing body that monitors or enforces testing standards. It is still important to verify that third-party certification is both correct and applicable for the project at hand.

Before publishing fire test results, PFP coating manufacturers get to review draft certifications against internal testing results and for standard applicability. If there are unexpected findings, the manufacturer can conduct further investigation to discover the reason for the discrepancy.

All stakeholders in the contract chain have a duty of care to both the building owner and its future inhabitants. It is not acceptable to transfer responsibility to the next agent in the chain — in fire safety, everyone is responsible.

Each fire test standard, such as UL 263, ASTM E119, EN 13381-8 and GB 14907, has its own specific protocols, temperature requirements and failure temperature definitions. All standards are designed to simulate the progression of cellulosic fires, but they cannot be used interchangeably — local or national building codes will specify the standard required for the project.

Building codes, such as the International Building Code (IBC), typically define PFP requirements by requiring that the products used meet recognized standards like UL 263 and ASTM E119. These building codes undergo revisions frequently to address new building types, safety concerns and load requirements for hazards such as earthquakes and tornadoes.

Contractors must be aware of these changing regulations, such as the withdrawal of the British Standard (BS) 476 standard series by 2029.4 This change means that projects may require fire protection testing to UL 263 or the European standard EN 1634-1.

With the complex provisions of building codes, fire safety codes and fire testing standards, developing PFP coatings that comply with all necessary requirements requires an extensive knowledge of all relevant industry standards and fire ratings as well as expertise in structural and fire protection engineering.

The Science of Fire Protection Testing

Fire testing of intumescent coatings is costly and time consuming due to the different types of structural configurations present in steel construction — and rightly so. Depending on the standard being tested, over 100 pieces of steel of varying sizes and shapes can be required, with the testing and analysis processes taking up to 18 months to complete.

Multiple factors can affect the performance of a PFP coating, including the section orientation, section factor (a ratio of surface area and thickness which determines the rate of heating), DFT of the coating and the applied loads.

PFP coatings are tested on individual steel section components and assemblies in unrestrained and restrained conditions.

Unrestrained conditions allow the steel to expand freely, simulating conditions where the steel is isolated within a structure.

Restrained conditions limit the expansion of the steel component, representing the supporting structures present in building constructions.

Tests are also conducted under loaded and unloaded conditions. Loaded tests simulate the loads placed on steel sections within structures using hydraulic rams.

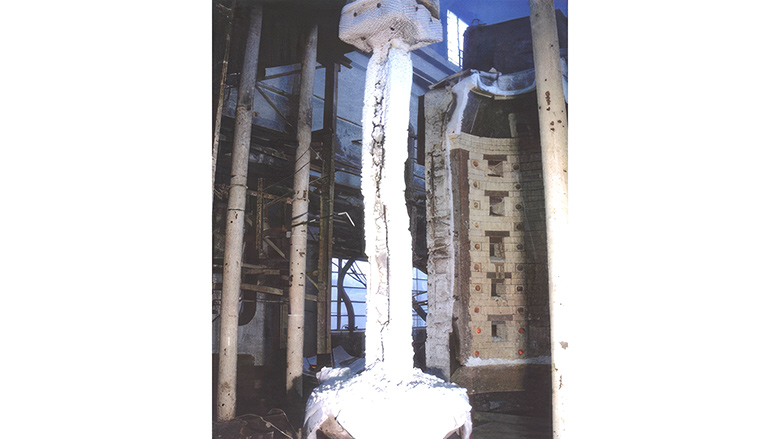

Loaded columns are tested for insulation and slumping, which can cause large areas of steel to become unprotected. For horizontal beam sections, loads are applied to the top flange and coatings are monitored for insulation and stickability.

Steel components are also tested as assemblies. Floor and roof assemblies are always loaded and can be tested in unrestrained and restrained conditions.

The fire testing results are used to create assessment documents that include DFTs for various steel section and assembly types. DFT tables in the assessment include coating thicknesses for various fire rating periods.

National building codes specify the required level of fire protection, which varies from region to region:

- 15/20 minutes: Popular in certain Eastern European countries

- 30/60 minutes: Used extensively in mainland Europe and UK

- 90/120+ minutes: Used globally in USCA/AP, the UAE, Africa and large projects in Europe

Why Accurate Testing Is Crucial

Accurate testing protocols that represent real-world building environments are crucial for PFP coatings. Variations in test conditions, such as slight differences in furnace temperature or inaccurate loadings, can all produce faulty results. This can lead to significant problems with extrapolated data that can cause delays and require costly modifications, or in the worst case, structural failure.

Maximum Allowable Loads

During fire testing, it is essential to test at the maximum allowable loads defined by structural engineering standards to determine accurate DFT requirements. One method is to use the standards developed by the American Society of Civil Engineers (ASCE), which writes technical guidelines related to load provisions and load combinations for buildings and other structures. These standards are used in various building codes and local regulations.

Maximum allowable loads tested in the appropriate configuration (e.g. a restrained assembly) are important because the loading of a steel section and its surrounding structures significantly impacts the adhesion and performance of the intumescent PFP coating. Higher loads can accelerate cracks and slumping, which reduces the amount of thermal protection provided by the coating and leads to structural failure.

System Compatibility

All primers and topcoats must also be tested for compatibility with intumescent PFP coatings. Untested primers can cause coatings to detach from the steel substrate before forming the insulating char, leaving the steel unprotected. Topcoats must be able to burn away quickly to allow the intumescent coating to expand. If the formulations are untested, they may impede this process and allow steel to heat up more quickly.

Cost Efficiency

Accurate testing supports improved cost efficiency throughout the entire service period of a structure. Exhaustive testing determines the necessary conditions and processes to ensure optimal coatings performance during application and in case of fires. Proper application and layering procedures can result in a service life of over 20 years with reduced lifecycle maintenance costs.5

When the PFP coating is applied at the appropriate DFT using approved primers and topcoats, fabricators can avoid costly re-works and delays. Maximum coating restrictions are just as important as minimum DFTs, as coatings that are applied too thickly can have problems with adhesion and develop cracks and fractures, requiring additional labor costs and repairs.

Thorough testing on different steel section types also ensures that the PFP coating is suitable for every size and shape of steel components used in architectural features.

Fire testing is a lengthy and expensive process, but it is a key part of delivering PFP coatings that provide effective fire protection. It is critical to select trusted coatings partners who adhere to rigorous testing and internationally recognized standards to ensure reliable performance.

Best Practices for Ensuring Compliance

To ensure an intumescent PFP coating is compliant with the relevant standards for a construction project, there are several checks that can help determine if the coatings meet the necessary specifications.

Ask the Coatings Supplier About the Standards Used to Test the PFP Coating

Suppliers should be able to provide information about which standards and methods were used to test the coating, where the fire testing was conducted (independent labs, in-house, etc.), assessment documents and technical data sheets. Suppliers should be readily willing to share this information.

Confirm Certifications When Possible

Some certifying bodies maintain databases of certified and approved products that meet their testing standards. For UL certified products, the status can be verified in UL Solutions’ Product iQ database.

FM Approvals, an organization that certifies loss-prevention products for commercial facilities, also records approved products in their online Approval Guide.

Verify the Local Building Codes

Ensure that the PFP coating has been tested to the appropriate standard listed in the relevant section of the relevant local building code). Standards should never be substituted; e.g. if a project specifies UL 263 testing standards, other standards, even if they may seem equivalent, should not be substituted.

The appropriate fire rating classifications should also be verified to ensure the PFP coating has been tested as it will be built on site. For example, a floor assembly that is coated according to a beam rating will not have the appropriate DFT.

It is necessary to perform testing and certification of the full system when there are several components to a particular structure. Products that are tested and certified on their own do not automatically function as certified when used in a system. Any system approach must have tested and certified evidence — there are no shortcuts when it comes to fire safety.

Collaborate with Trusted Partners Who Prioritize Transparency in Testing

It is important to choose a coatings supplier with a proven track record of reliable performance with records and documentation detailing past projects. Coatings suppliers should be able to provide data to back up performance claims.

When it comes to fire protection, a commitment to comprehensive and rigorous testing, along with the willingness to share information about trials, test processes and results, helps ensure that the PFP system will be installed correctly and function as intended in an actual fire.

PPG Case Studies: Proven Success in Fire Protection

PPG has a documented track record of providing reliable fire protection solutions that perform in even the harshest environmental conditions. Research on cellulosic PFP solutions began in 2011, and the PPG Steelguard range of products was first launched in 2013.

PPG utilizes in-house facilities, such as a dedicated UL-certified Global Fire Protection Technology Center, and extensive third-party testing to develop products that meet and exceed global fire protection standards while also delivering operational advantages and appealing aesthetic finishes. The PPG PFP team has decades of experience working in the fire protection industry and extensive experience in structural engineering and fire engineering.

PPG Steelguard products protect transportation hubs, sports facilities, and civil buildings around the globe.

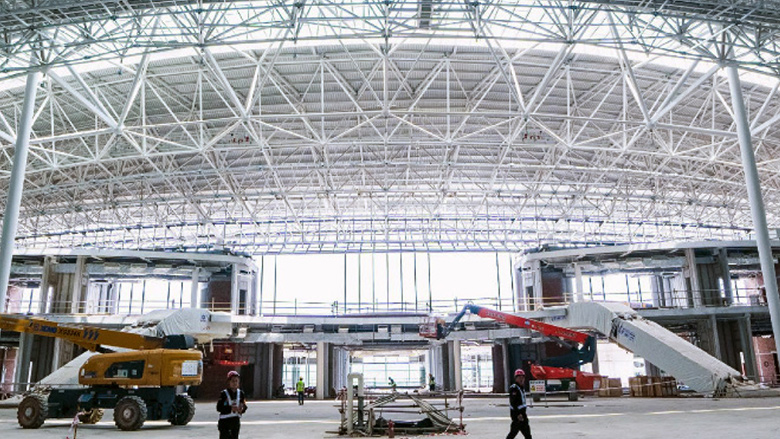

T3B Terminal

The T3B Terminal at Chongqing Jiangbei International Airport is the world’s largest single satellite hall, covering over 3.8 million square feet. The design includes a steel roof system with a double-layer curved truss and a large-span spatial truss and interior structures such as the Dalian Bridge. The project required not only fire safety and corrosion protection, but also visual appeal and cost efficiency.

Construction teams needed a PFP solution that could meet the performance requirements of China’s GB51249-2017 standards while providing long-term durability. PPG PFP and topcoat solutions were selected for their proven performance and ability to maintain a smooth, visually appealing finish on exposed steel elements.

Manufacturing Facility

PPG’s Steelguard 951 intumescent coating was chosen for a manufacturing facility in Kigali, Rwanda, with a short construction timeline of only four months.

Its fast-drying system enabled rapid production, ensuring efficiency in application. The coating's excellent toughness allowed transportation shortly after application.

Building Resilience with PFP Coatings

Accurate fire testing and compliance with industry standards are essential to ensure the reliability of PFP coatings. Variations in application thickness, building loads and environmental conditions can significantly impact performance, and a commitment to rigorous testing and transparent data reporting is vital. Selecting coatings that adhere to internationally recognized standards and have undergone extensive validation ensures optimal fire protection, structural resilience, and cost efficiency throughout the operational life of the structure.

The complexity of fire protection regulations and the high stakes involved make it imperative for fabricators, contractors and property owners to work with trusted suppliers who can provide transparent, verifiable data and a proven track record of performance. All the players in the commercial construction industry must take responsibility to provide tested and certified — and most importantly, safe — solutions.

As a leader in intumescent PFP solutions, PPG is dedicated to advancing fire safety through advanced research, extensive fire testing and adherence to fire protection standards. From sports stadiums and office buildings to manufacturing and industrial facilities, PPG Steelguard coatings have proven their reliability in delivering fire protection, corrosion resistance and aesthetic excellence.

References

1 Steel use by sector, World Steel Association.

https://worldsteel.org/data/steel-use-by-sector/.

2 Facts for Steel Buildings: Fire, American Institute of Steel Construction, Inc.

https://www.aisc.org/globalassets/aisc/publications/facts-for-steel-buildings-1-fire-facts.pdf.

3 Architecturally Exposed Structural Steel, American Institute of Steel Construction.

https://www.aisc.org/architecture-center/architecturally-exposed-structural-steel/.

4 Approved Document B (Fire Safety): new updates to support enhanced fire safety, Ministry of Housing, Communities & Local Government.

https://www.gov.uk/government/publications/amendments-to-approved-document-b-fire-safety-circular-and-letter/approved-document-b-fire-safety-new-updates-to-support-enhanced-fire-safety.

5 Durability of intumescent coatings and recommendations for test concepts for a working life of more than 10 years, Fire Safety Journal.

https://www.sciencedirect.com/science/article/pii/S0379711224000869?dgcid=rss_sd_all#bib16.

Access the full white paper here.

Fire testing standards and certification requirements continue to shape how industrial coatings are specified for structural steel applications.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!