New Fluorosurfactants Address Environmental Concerns Surrounding C8 Telomer Chemistries

While some companies have not yet abandoned their C8 fluorosurfactants, change certainly seems inevitable. The U.S. EPA has been investigating analogous C8 and longer chain fluorochemicals produced from a telomerization process. The agency recognizes the potential health hazard these materials represent and is focusing its efforts on identifying levels, pathways and sources of human exposure. Its hazard assessment will soon undergo peer review. In Europe, these materials are under similar scrutiny.

Environmental Concerns

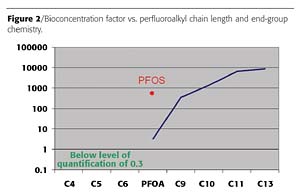

A number of recently published studies document the potential environmental impact of the C8 and longer chain telomer products and their degradants, most notably by Professor Scott Mabury and his team at the University of Toronto. Highlights of their work show that:- Bioaccumulation factors of certain fluorochemicals increase as a function of chain length (Figure 2).

- Atmospheric concentrations of C8 telomer alcohols are significant at specific sites in North America.

- Concentrations of perfluoroalkyl acids are found in the blood/tissues of arctic species (Figure 3).

- Degradation pathways exist for telomer alcohol oxidation to C8 and longer chain perfluoro acids in wastewater treatment sludges and under atmospheric conditions.

Professor Mabury went on to say, "Fluorochemicals are highly useful to society, yet we have a chemical pollution issue. The key to control of this class of chemical is to reduce residuals and products that can degrade to the telomer alcohols, shorten perfluoroalkyl chain lengths to avoid bioaccumulation, and prudently select linkage chemistry for stable non-releasing materials."

Work also continues under the direction of the EPA and the Telomer Research Project consortium to better understand the environmental fate and pathways to human exposure of PFOA, a degradant of telomer fluorosurfactants. The ‘PFOA' acronym is used to indicate perfluorooctanoic acid and other perfluoro carboxylic acids that are degradants of telomer fluorosurfactants, and not the ammonium perfluorooctanoate salts APFO. This work, along with the EPA Hazard and Risk Assessments, may result in application of appropriate controls for C8 and longer chain perfluoroalkyls and their degradants.

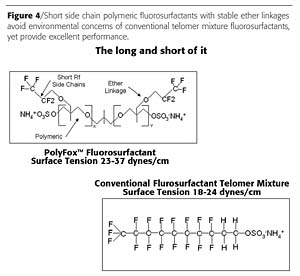

Interestingly, PolyFox materials appear to follow Dr. Mabury's recipe. The novel oxetane chemistry provides a polyether backbone, short perfluoroalkyl side chains, and stable ether linkages, in sharp contrast to conventional materials (Figure 4).

Partnering Strategy

OMNOVA Solutions adopted a proactive cooperative strategy with global chemical regulatory authorities as the new fluorosurfactant technology platform transformed into a commercial product portfolio. Working with the U.S. EPA, the U.K. Health and Safety Executive and Environmental Agency, and METI in Japan, only those short side chain, polymeric, fluorosurfactant structures that the regulatory authorities agreed would have little human health or environmental impact have been pursued."We have uniquely tailored structures that meet both the demands of our customers for performance and the demands of the global regulatory authorities to assure that there are no environmental issues," said Bill Beers, global chemical regulatory manager for OMNOVA. "This strategy has led to full regulatory approvals for PolyFox fluorosurfactants in the United States and Europe and the ability to continue technical programs for new product development."

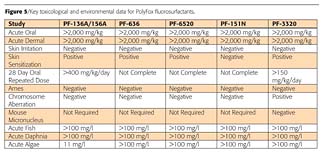

Working with NOTOX Laboratories in the Netherlands, OMNOVA Solutions has completed the required physical/chemical, toxicological and environmental studies to assure that these new fluorosurfactants have minimal environmental impact. A family approach and read-across methodologies were utilized with the U.K. authorities to minimize animal testing and focus studies on those products at the boundaries of the fluorosurfactant platform in terms of molecular weight, side chain length and end-group chemistries.

The key data for a representative cross section of the PolyFox fluorosurfactant platform are summarized in Figure 5 and confirm that there are no significant risks to human health or the environment. Bioaccumulation studies for these short side chain fluorosurfactants were conducted and show that these materials do not bioaccumulate.

"Our strategy has been full cooperation with all global regulatory authorities and full transparency to provide the environmental data to anyone interested," said Beers, "and we work closely with environmental contacts at many of our leading customers."

Unconventional Performance

In addition to meeting health and environmental goals, this potential replacement chemistry also has strong performance attributes. Important application benefits are achieved by tailoring the polymeric structures:- Flexible side chains concentrate fluorine on the coating surface rather than burying it in the bulk coating. This enables efficient material use.

- The polyether backbone combined with short CF3 or C2F5 fluoroalkyl groups provide excellent compatibility in a range of paint and coating systems; conversely, long perfluoroalkyl chain chemistries have limited compatibility in many systems.

- Engineered polymer end-group chemical functionality provides reactive sites for modifying solvent, waterborne and 100% solids UV/EB coating systems, and for incorporating into resin systems such as polyesters or polyurethanes.

- PolyFox fluorosurfactants generate very low foam. Not only is foam destabilized, but excellent deaeration is obtained for porous or grained surfaces. Air entrainment, even in spray-applied coatings, is minimized.

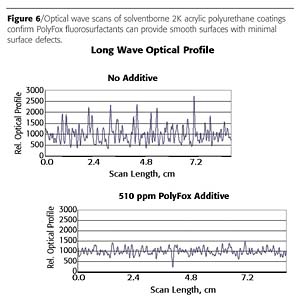

- Extremely flat surfaces are achieved, as shown in the wave scans of Figure 6, over a range of coating chemistries and substrates.

- The technology can provide synergistic performance in blends with certain non-fluorochemical leveling agents to eliminate coating problems like picture framing, air entrainment or cratering.

- PolyFox fluorosurfactants are effective at low concentrations, often down to a few hundred ppm in aqueous coatings, which can make them cost effective compared with non-fluorochemical surfactants that require treat rates that are an order of magnitude higher.

Commercial Successes and Opportunities

A real challenge for the PolyFox business team has been to keep pace with the rapidly growing number of potential end use applications. "The scope of new opportunities is so wide that we continually seek leading edge development partners who can provide the in-depth applications know-how required for commercial success," said Joe Twitchell, OMNOVA's PolyFox Sr Marketing Manager. "We have recently formed this type of partnership with a leading contract wood coatings applications laboratory in the United States and with Innovia Solutions in the U.K. to increase our efficiency in providing economic customer solutions to their new applications problems."The initial commercial application for these new fluorosurfactants was floor polishes, and there are about 50 customers around the world currently using PolyFox materials. This number continues to grow as floor polish manufacturers are moving away from conventional C8-based fluorosurfactants in both industrial and residential formulations.

New commercial applications in coatings for PolyFox fluorosurfactants highlight the wide range of potential end uses.

For example, OMNOVA has formulated it into topcoats for its own vinyl film laminate products (Figure 7). For several years, the company has used a PolyFox diacrylate reacted into a scratch-, abrasion- and stain-resistant UV-cured top coat. The technology has now been extended to UV-cured overprint varnishes to improve wetting for hard-to-coat "greasy" surfaces. In addition, durability, cleanability, blocking resistance and clarity of the printed surfaces are enhanced.

PolyFox fluorosurfactants have been developed for superior urethane leather topcoats. The air entrapment and mottling effects typically observed when coating dark leathers are eliminated. Dark leathers may now be top coated economically in one pass (Figure 8).

A PolyFox diol is being used by a specialty U.S. paint company, XIM, to produce a unique, solvent-based 2K urethane anti-graffiti coating. "The performance levels achieved are unheard of in this industry," said Juan Jarufe, XIM's Vice President of Research. Effectively permanent markers bead up and are easily removed (Figure 9). Several European companies are now evaluating these coatings in a range of applications. Jarufe added, "We are working with OMNOVA to provide this same level of graffiti resistance in waterborne PUD-based systems and market interest is very strong. We have not yet achieved the level of performance we're after, but we remain optimistic that the PolyFox fluorosurfactants can give us the performance we need."

- Electronics coatings that improve the uniformity of coating depth at the angstrom level, particularly critical when coating large, complex surfaces;

- Low-refractive-index adhesive coatings for glass and polycarbonates with good wetting and scratch resistance;

- Coil coatings for refrigerator panels with improved surface cleanability;

- Two-part epoxy maintenance paints that eliminate craters and orange peel;

- Aerospace coatings for windshields to provide smoother surfaces with lowered air drag;

- Automotive aftermarket clear coats that improve clarity/distinctness of image at higher levels of gloss.

Evolving Potential

Clearly, polymeric short side chain fluorosurfactants present a viable replacement as paint and coating producers look to move away from C8 chemistries for environmental reasons. It is equally evident that this technology platform has the broad potential to provide important performance advantages over a wide range of applications. Flow, leveling and wetting can now be combined with improved surface durability for existing and new end uses.As OMNOVA's Joe Twitchell points out, "This novel short side chain flourochemistry is in the early stages of its life cycle. Much development work remains with interested customer/partners to transform technical features into commercial benefits. We have not even scratched the surface."

For more information about PolyFox fluorosurfactants, contact Joe Twitchell, PolyFox Market Manager, OMNOVA Solutions Inc., 803/377.2234, e-mail JP.PolyFox@omnova.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!