Novel Pigment Dispersing Agent Produced by Emulsion Polymerization

Investigation Purpose

The aim of the current investigation was to evaluate the performance of EFKA-4580 compared to other commercial dispersing agents; therefore it has been tested in one of the most critical ways, which consists of formulating highly filled resin-free pigment concentrates (RFPC) and evaluating them quantitatively and qualitatively in a series of lacquers. This test method distinguishes the dispersants with regard to wetting efficiency, paste stability, compatibility and physical performance of the dry film.As benchmarks, the following two products were used:

- HMWD agent EFKA-4560, which is soluble in water due to the polar side chains on the polymer backbone. After drying, it is not re-soluble in water but, due to the presence of these polar groups, a coating containing EFKA-4560 has a tendency to be water sensitive.

- Competitive material, also tested, is based on polyether modified copolymers and is in use by the paint industry. It is expected that this product is also water sensitive since it is water-soluble.

The new polymer EFKA-4580, since it is an emulsion, has fewer water affinic groups compared to EFKA-4560 and does not need to be neutralized to become water compatible. Therefore, a higher water resistance is expected for the dry film containing EFKA-4580.

During the product design, EFKA-4580 was equipped with another advantage in addition to the improved water resistance: excellent wetting properties for organic pigments with high BET values. This enables the paint industry to make extremely high loaded RFPCs with low, nearly Newtonian viscosities and good overall stability.

Decorative Paints

As a first example, resin-free pigment concentrates based on the three dispersants and Heliogen Blue L 7080 were prepared according to the formulations in Table 2.All pastes contain 43% of pigment at the same active dispersant concentration, no grinding resin was used, and only water was present as a solvent.

EFKA-4580 showed the lowest viscosity and most Newtonian behavior (Figure 1). After several weeks of storage at elevated temperatures (Figure 2) the viscosity was nearly unchanged. EFKA-4560 tends to build up viscosity in the RFPC, and for the competitive material the RFPC viscosity decreased during this test, which indicates a lower dispersion stability.

It should be noted that pigment choice in this type of application is critical to the success of the concentrate formulation. Differences in pigments of the same grade can exist. These differences can be attributed to processing techniques or surface treatments. The differences can vary widely and affect the overall stability, rheology and color development of a pigment concentrate. Care must be taken when choosing a pigment for the preparation of pigment concentrates based on the RFPC concept.

It was noted that in a solventborne long-oil alkyd paint, EFKA-4580 and the competitive concentrates showed no compatibility, which emphasized that both products are only designed for waterborne applications. EFKA-4560 showed a moderate color development; that is why this product is used in combination with a dispersing resin for producing universal deco concentrates.

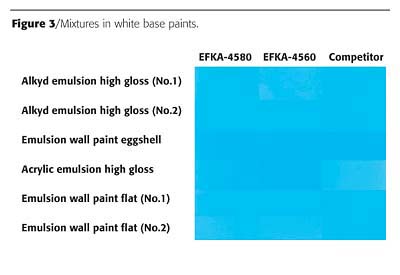

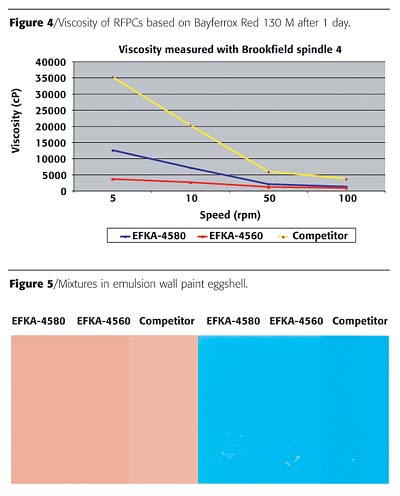

Figure 3 shows that the EFKA-4580 concentrate, in general, gave a uniform color development in all mentioned waterborne decorative white paints. The slight shade differences seen in the drawdowns in Figure 3 are due to differences in:

- titanium dioxide level of the paints (various paint manufacturers)

- amount and type of extenders

- surface (gloss versus matt)

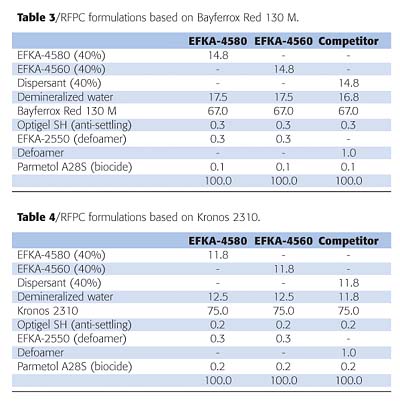

Inorganic pigments Bayferrox Red 130 M (Table 3) and Kronos 2310 (Table 4) were chosen for this study. It can be seen from Figure 4, based on Bayferrox Red 130 M (pigment load 67%), that at high shear rates (50-100 rpm) EFKA-4580 and EFKA-4560 showed almost similar viscosities, while at low shear rates (5-10 rpm), EFKA-4580 developed a slight thixotropic structure, which can be an advantage to prevent settling problems. The competitive material showed an undesired build up of thixotropic structure at low shear rates.

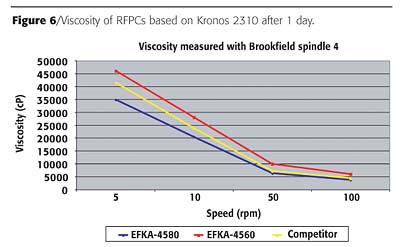

In the case of the white concentrates (pigment load 75%, Table 4), no significant differences in viscosities were observed between the three products (Figure 6).

Industrial Paints

To further evaluate the color development, compatibility and humidity resistance, industrial paints were produced with two previously mentioned pigment concentrates (one containing 75% of titanium dioxide, Table 4, and another containing 43% of phthalocyanine blue, Table 2). These paints were based on the following waterborne clear resin systems:- 2-pack polyurethane;

- 2-pack epoxy;

- Stoving enamel;

- Pure acrylic dispersion;

- Modified acrylic dispersion;

- Alkyd urethane emulsion.

The components were mixed in the following ratios:

- 75 wt% solid binders of above resins;

- 20 wt% white concentrates based on Kronos 2310;

- 5 wt% blue concentrates based on Heliogen Blue L 7080.

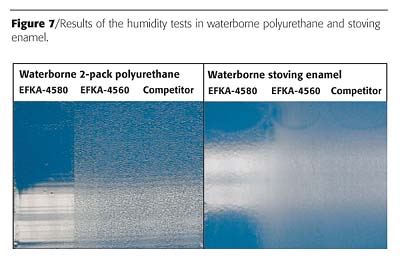

Humidity-resistance tests were carried out as follows: For each resin system, three films (based on the individual dispersants) were applied next to each other on one aluminum Q-panel (75-µm wire-bar) and tested after 7 days of drying (stoving enamels were cured for 20 min at 150 °C), by exposure at 40 °C for 360 hours in a humidity/condensation cabinet.

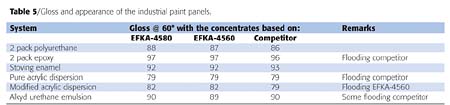

Humidity test results confirm the assumption that paint films based on EFKA-4580 show a much stronger water resistance than those with the two more water-sensitive dispersants (Table 6). Only in the case of the alkyd urethane emulsion all the products failed, which is ascribed to the high polarity of this specific resin system.

In two cases, all three products showed an intact film, however Figure 7 shows the positive effect of the improved water resistance of EFKA-4580, while both EFKA-4560 and the competitive dispersant lead to strong deterioration of the films under the same conditions.

Summary of the Test Results

EFKA-4580 offers the following advantages:- Low viscosity and good stability of resin-free pigment concentrates;

- High pigment loading is possible (43 -75% depending on type of pigment);

- Uniform color development in various waterborne decorative paints and waterborne industrial clear coatings;

- High gloss of the cured films;

- Excellent compatibility with all kinds of waterborne paints (industrial and decorative);

- Advantageous anti-flooding behavior;

- Outstanding humidity resistance.

Conclusion

The new product EFKA-4580 is a versatile polymeric dispersant that shows strong deflocculation of all kinds of organic and inorganic pigments. There are several application advantages, and some of them are attributed to the innovative product form - an emulsion polymer.EFKA-4580 is suitable for ultralow-VOC (< 5 g/L = < 0.042 lbs/gal) applications and is compatible with a wide range of commonly used waterborne decorative and industrial coatings, as well as for the formulation of resin-free pigment concentrates.

For more information contact william.wagner@efka.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!