Biocatalytic Coatings

Since the 1700s and the introduction of calf stomach as a "bioreactor" for the production of cheese, enzymes have assumed an ever-expanding role in industry and technology. This has largely come about as a result of an evolving understanding of protein structure function. For example, in 1894 the Dutch chemist Emil Fisher proposed that enzymes and their substrates fit together like a "lock and key," and many industrial enzymes are valued today for just that reason, being both very efficient and very specific catalysts. However, some of the most significant industrial enzymes with respect to market volume are detergent proteases. The commercial success of these enzymes is based on many factors, not least of which is their relatively low substrate specificity.

Enzymes, like the detergent proteases, have provoked a reevaluation of the "lock and key" paradigm, resulting in a new understanding that recognizes that the interacting molecules are flexible and can change their shape during the recognition process. Similarly, enzymes have traditionally been thought to be functionally restricted to very narrow environmental conditions, yet there is a growing awareness of enzymatic reactions that can occur in nonaqueous environments1 and of enzymes with temperature, salt, pressure and pH tolerances that exceed normal enzymatic ranges as isolated from extremophilic organisms.2 A new understanding of biochemical capabilities of enzymes is leading to the development of innovative, biocatalytic "smart coatings" by a new additive company, Reactive Surfaces Ltd. (RSL). The first area in which RSL biocatalytic coatings are demonstrating great promise is in the area of self-decontaminating coatings.

Chemical-Agent Decontamination

Current Approaches

Many organophosphorus (OP) compounds are potent cholinesterase inhibitors, accounting for their widespread use as insecticides and chemical warfare agents. Common OP agents include the chemical warfare agents tabun (GA), soman (GD), sarin (GB), cyclosarin, VX and its isomeric analog Russian VX (R-VX). Historically, most approaches to chemical-agent decontamination are post-exposure, focusing on the treatment of surfaces after exposure has occurred and been subsequently detected. Post-exposure decontamination technologies currently available include the application of caustic solutions and foams, applications of superoxides, use of intensive heat and carbon dioxide applied for sustained periods, and incorporation of materials (TiO2 and porphyrins) into coatings that, when exposed to sustained high levels of UV light, will degrade chemical agents.

Although each of these approaches can be effective under specific conditions, a number of limitations exist. Caustic solutions and superoxides degrade surfaces, create personnel handling and environmental risks, and require transport and mixing logistics. Foams require transport and present mixing logistics, may have personnel handling and environmental risks, and are not effective on sensitive electronic equipment or interior spaces. Decontamination with heat and carbon dioxide presents logistical requirements and does not allow for rapid reclamation of equipment. UV-based approaches can be costly and have logistical requirements, including access to UV-generating equipment and power.

A New Approach

Enzyme-based decontamination has been a longstanding research objective for a number of civilian and military research labs, notably those at Texas A&M University and U.S. Army research facilities. Over the past decade, this research has significantly expanded our understanding of the enzymes that degrade chemical agents. However, to date there has been limited success in using conventional approaches to harness the potential of these enzymes in systems that can be used readily and cost effectively for field-based military or civilian applications. Building upon the extensive base of scientific knowledge acquired over the past decade, RSL is commercializing novel enzyme additives that not only remain stable in paint but, remarkably, remain active for extended periods of time.

RSL has developed OPDTOXTM, a self-decontaminating coating additive that is biocatalytic in nature and which represents a paradigm shift for chemical-agent decontamination. OPDTOX can serve either as a stand-alone decontamination method or as a complementary approach to existing decontamination techniques and products. When added to coatings, RSL additives create a reactive surface that will initiate the process of decontamination immediately upon exposure to organophosphorus pesticides and neurotoxins. Applied in advance of exposure, painted surfaces containing OPDTOX can continue to degrade OP compounds after repeated exposures and remain active following washing. The scientific basis of the product lies in the ability of bacterially derived enzymes to efficiently degrade OP compounds. The results are novel coatings that self-decontaminate following exposure to organophosphorus compounds, which includes many important environmental and security targets such as the nerve agents VX, GD, GB, thickened nerve agents, and pesticides such as malathion, parathion and coumaphos.

The Enzyme of Choice

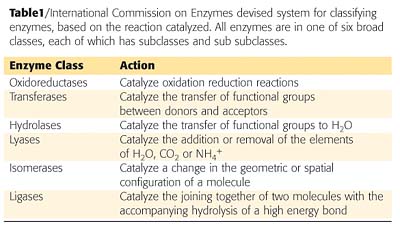

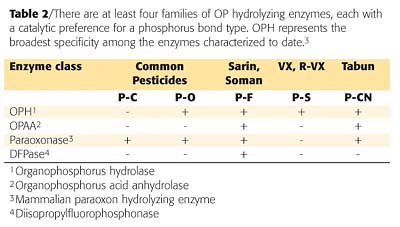

The enzyme of choice for OP decontamination is organophosphorus hydrolase. Of the six major groups of enzymes (Table 1), approximately 80% of industrial enzymes are hydrolases. Hydrolases are enzymes that catalyze the hydrolytic cleavage of C-O, C-N and C-C bonds. A class of hydrolase known as organophosphorus hydrolase (OPH) can also cleave the P-O, P-F and P-S bonds of the organophosphorus compounds.Of the currently stockpiled nerve agents, VX is the most toxic, as well as the most persistent in the environment after release. In addition to the initial inhalation route of exposure common to such agents, persistent agents such as VX and thickened soman pose threats through dermal absorption.

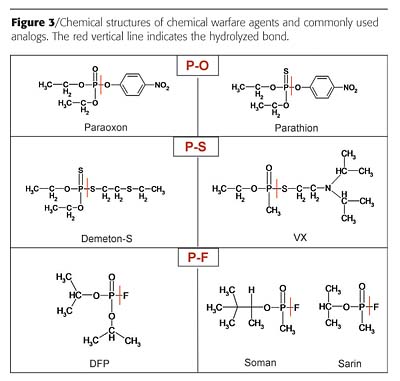

Enzymatic hydrolysis of OPs occurs when the compound is cleaved at the phosphoryl center's chemical bond, resulting in predictable byproducts that are acidic in nature but benign from a neurotoxicity perspective (Figure 1). By comparison, chemical hydrolysis can be much less specific, and in the case of VX, may produce byproducts that are extremely toxic. Although a number of enzymes have been identified that are capable of detoxifying OP compounds, OPH has the broadest substrate specificity (Table 2). The substrate range of OPH includes numerous insecticides (paraoxon, parathion, coumaphos) and the neurotoxic chemical warfare agents and their analogs. Catalytic specificities for this family of compounds have been shown to range from rates that are diffusion limited (e.g. paraoxon, P-O bond, kcat=104 sec-1) to rates that are six to eight orders of magnitude lower (e.g. acephate, P-N bond).4 The enzyme is composed of two identical monomers associated to form a remarkably stable dimeric enzyme (Figure 2), with a thermal Tm of approximately 75

Biocatalytic Paint Surfaces

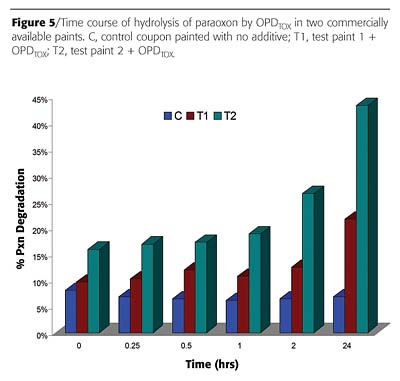

Both chemical warfare agent and surrogate tests have been conducted on metal and wood surfaces painted with commercially available latex paint containing OPDTOX additives. Figure 5 illustrates the results from a surface test in which 1 x 10 cm aluminum coupons, coated with OPDTOX treated paint, were contaminated with the OP pesticide paraoxon (1 mg/cm2), allowed to react for the indicated times, extracted in isopropanol and then analyzed for the hydrolysis product p-nitrophenol by gas chromatography. In this study, two different "off-the-shelf" paints were compared. While these studies demonstrate significant decontamination with either paint, they also illustrate that reactivity can be further optimized and enhanced with tailored paint formulations. Additional studies indicate that coatings may be optimized for hydration levels and additive capacity to tailor these biocatalytic coatings for specific applications.

At the September 2002 meeting of the NATO Army Armaments Working Group (WG-31) in France, a limited number of RSL's painted surfaces were tested for efficacy in decontaminating soman using standard NATO procedures and protocols. For the tests, 10 cm x 10 cm steel plates were coated with paint containing OPDTOX. Control plates plus two different versions of the OPDTOX additive were prepared. These surfaces were allowed to dry for several hours at room temperature and then tested following standard NATO protocols. OPDTOX painted surfaces were uniformly contaminated with the chemical warfare agent soman (1 mg/cm2 per coupon). The contaminated plates were maintained at or slightly above room temperature (>20 °C) without any forced airflow for various periods of time. At zero-time, 15 minutes, 30 minutes and 45 minutes, a sample was taken for each control and additive-containing plate series by submerging in isopropanol at the end point and placing on a shaker to thoroughly extract any residual nerve agent. Figure 6 illustrates the results, demonstrating that the two different OPDTOX additives tested detoxified the soman at levels over 65% and 77% after 45 minutes.

Shelf-Life Potential

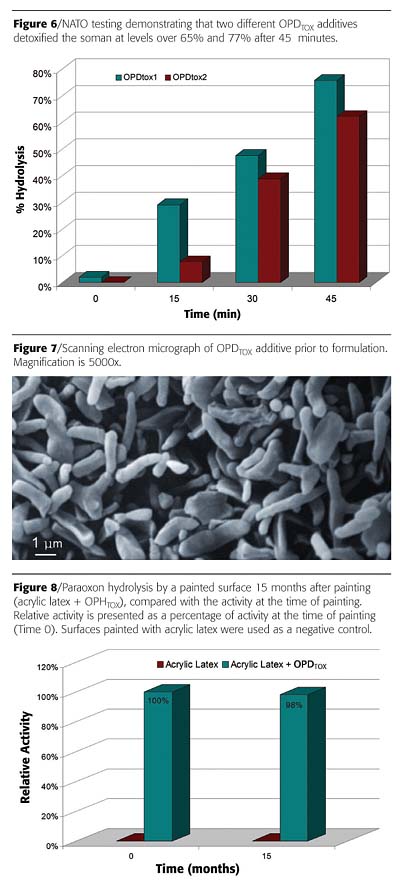

Monitoring the shelf life of RSL's OPDTOX additive prior to formulation into a coating has shown that the additive remains active for years when stored as a dry powder at room temperature (Figure 7). In addition, monitoring the life of RSL-active coatings on test surfaces indicated that the additive in coatings remains active for sustained periods of time. All prepared surfaces were preserved in airtight plastic containers at ambient temperatures. Initial rates of substrate degradation by surfaces prepared with RSL coatings were tested in a buffered aqueous reaction. The activity was assayed just after painting and then again after 15 months, demonstrating maintenance of the activity profile of RSL coatings (Figure 8). In addition, the coatings have qualitatively demonstrated activity up to 26 months after preparation.

Why Enzyme-Based Catalytic Coatings?

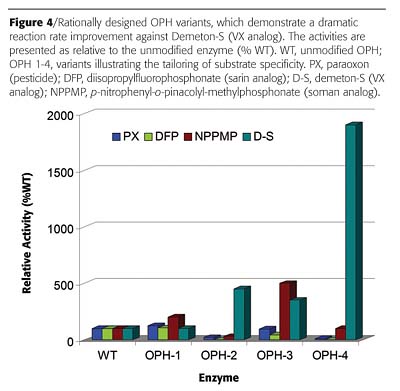

Enzymes offer substantial advantages over chemical catalysts in a traditional industrial environment. They are biodegradable, work under mild conditions, often can provide benign alternatives to existing processes, and are not associated with the production of hazardous by-products or secondary waste. The current technology for OP decontamination involves the application of caustic solutions, foams, intensive heat and carbon dioxide for sustained periods. The biocatalytic coatings described here bring a new technology to bear on this problem, offering an opportunity for OP decontamination without the environmental impact. But equally important is the adaptability of OPH-based additives. Much like subtilisin, which provides the scaffolding for all the detergent proteases currently in use, OPH has the broad substrate specificity to handle the major classes of OP neurotoxins. And, with the rapidly increasing database of natural enzyme diversity, and recombinant DNA technologies, the protein modification tools exist today that will allow OP biocatalytic coatings to be tuned to a specific application.By tailoring enzymes for specific purposes, RSL is developing additives and mixtures of additives that have been bioengineered to exhibit increased activity and/or specificity for one or more chemical warfare agents. Similarly, RSL is investigating methods and formulations that are designed to increase the active life of the additive in paint on surfaces. While there are a large number of potential military applications for self-decontaminating surfaces, RSL's self-decontaminating technology has numerous non-military commercial applications as well.

The development of cost-effective, self-cleaning surfaces will mitigate contact hazards for first responders, decrease the time needed for reclamation of contaminated spaces, and minimize environmental impacts commonly experienced with caustic solutions and foams. RSL is expanding the enzyme-based additives for coatings into areas that should allow for self-cleaning surfaces, mold-inhibiting surfaces, deodorizing surfaces, textile coatings, and catalytic coatings for waste stream decontamination. If RSL's success is a guide to the future, the limitations for uses of active biomolecules in "smart coatings" does not appear to be with the technology, rather only with the imagination of the paint chemist.

Acknowledgements

We would like to thank Dr. M. Pendleton and Ann Ellis of the Microscopy and Imaging Center at Texas A&M University for assistance with the electron microscopy experiments.

For more information, contact Steven McDaniel, Reactive Surfaces, Ltd., 300 West Avenue, Austin, TX 78701; 512/472.8486; fax 512/472.8181; or e-mail smdaniel@reactivesurfaces.com.

References

1 Krishna, S.H. Developments and Trends in Enzyme Catalysis in Nonconventional Media. Biotechnol. Adv. 2002, 20:239-267.2 Eichler, J. Biotechnological Uses of Archaeal Extremozymes. Biotechnol. Adv. 2001, 19:261-278.

3 DiSioudi, B.D.; Miller, C.E.; Lai, K.; Grimsley, J.K.; Wild, J.R. Rational Design of Organophosphorus Hydrolase for Altered Substrate Specficities. Chem.-Biol. Interact. 1999, 119-120:211-223.

4 Lai, K.; Stolowich, N.J.; Wild, J.R. Characterization of P-S Bond Hydrolysis in Organophosphorothioate Pesticides by Organophosphorus Hydrolase. Arch. Biochem. Biophys. 1995, 318 (1):59-64.

5 Grimsley, J.K.; Scholtz, J.M.; Pace, C.N.; Wild, J.R. Organophosphorus Hydrolase is a Remarkably Stable Enzyme That Unfolds Through a Homodimeric Intermediate. Biochemistry 1997, 36:14366-14374.

6 McDaniel, C.S.; Harper, L.L.; Wild, J.R. Cloning and Sequencing of a Plasmid-borne Gene (opd) Encoding a Phosphotriesterase. J.Bacteriol. 1988, 170:2306-2311.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!