Processing In-Mold Waterborne Coatings

The in-mold process allows for a quicker processing time and takes up less space than a post-paint application. Most post-paint applications require between 40 and 60 minutes to process and require power wash equipment, spray lines and ovens. The plastic in these applications requires cleaning, degreasing and priming before it can be painted with a topcoat. Even with this extensive preparation, defects are very common and costly to the finisher. Post-paint applications require skill and finesse to properly apply the coatings, and still surface defects such as picture framing, sagging, orange peel, craters and dirt contamination commonly occur. The post-paint process also requires that ovens be maintained at proper temperatures to appropriately cure the post-paint finish; a delicate and energy-intensive proposition.The in-mold process allows for parts to be molded and coated in a one-step process so that finishers do not have to use multiple steps to mold and paint the part. This eliminates many plastic preparation costs (cleaning, degreasing, priming, sanding, flame treating, etc.) and uses less packing and shipping, less labor, and produces less waste, thereby generating a substantial cost savings for the finisher.

The cycle time to produce a steering wheel or instrument panel (IP) skin with an in-mold coating can range from three and a half to five minutes, depending on the mold temperature and the type of elastomer. The part and the in-mold coating are fully cured and chemically bonded to one another during the molding process, eliminating the need for bake ovens as in post-painted parts.

With an in-mold paint application, the visible coating surface will appear as an exact replica of the mold tool. Therefore, by using this application, defects such as picture framing, sagging, cratering and orange peel are inherently eliminated. As long as the mold surface is clean and the equipment settings for the mold temperature are correct, the in-mold coating will dry shortly after as it comes in contact with the tool.

Waterborne in-mold coatings allow for the use of lower-VOC coating due to the application of the coating to a hot tool. Typical solvents used for coalescence and appearance control during the curing process are not necessary. The VOCs of the waterborne in-mold coatings can range from 0.4 - 1.8 lb/gal, depending on the type of coating. A flexible waterborne in-mold coating will contain 0.4 - 0.7 lb/gal VOC, while a soft, "leather-like-feel" two-component coating will run in the 0.8 - 1.8 lb/gal VOC range. Post-paint waterborne coatings can range from 1.2 - 2.8 lb/gal VOC.

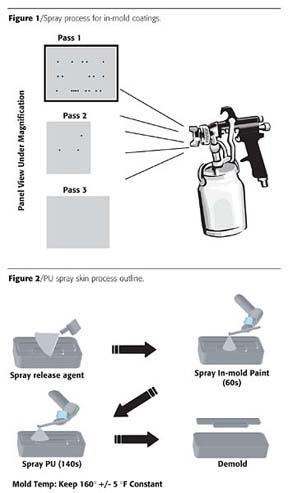

The primary concerns when using in-mold coatings are flash time and a condition known as "Wet IMC". Wet IMC happens when blistering and delamination occur between the coating and the substrate. This condition can arise from short flash time, high DFT or poor application. Wet IMC most generally occurs when the coating is applied too heavily in a single pass. Solvent becomes trapped in the coating, which results in blistering and poor adhesion between the substrate and the paint film. This can be corrected by first selecting equipment that will properly atomize the coating, and then using multiple passes to slowly build to the desired DFT, thus eliminating issues associated with wet IMC.

It is common to see pinholes and imperfections in post-paint applications when evaluating the film closely under magnification. As stated earlier, in-mold coatings do not utilize low levels of coalescing solvents. In an in-mold application, slow solvents are ineffective at coalescing and facilitating flow-out over a hot tool because the coating hits the mold and dries almost immediately on contact, resulting in very little flow. The excellent film quality is achieved then, not by the typical flow and coalescing manner but by applying the coating with multiple passes and good atomization so that the paint film is uniform and free of blisters and pinholes (Figure 1).

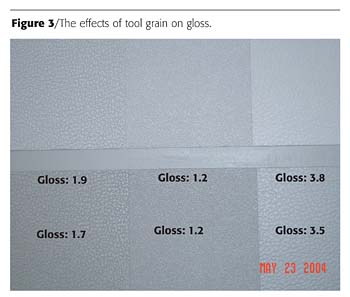

Listed below is a step-by-step process description for producing a finished part by the in-mold process.

Polyurethane spray skin (instrument panel)

- 1. The mold is heated and kept at a constant temperature of 160 +/-5 °F through water circulation.

2. Mold release is applied (15 - 30 sec.) followed by a 10 - 30 sec. flash. The mold release can be semi-permanent or sacrificial (one release/application). Sacrificial-type release is preferred at this time due to ease of release, low gloss and part-to-part gloss consistency.

3. Coating is applied at 0.8 - 1.5 mils to the top and bottom of the tool (60 sec.), followed by a 10 - 60 sec. flash.

4. Two-component polyurethane (PU) elastomer is applied to the tool at approximately 1.0 mm thickness (60 sec).

5. The skin is allowed to cure in the tool for 60 sec. prior to demolding.

6. The skin is prepared for the next station (backing) (Figure 2).

-

1. The mold is heated and kept at a constant temperature of 160 +/-5 °F through water circulation.

2. Mold release is applied (15 - 30 sec.), followed by a 10 - 30 sec. flash. The mold release can be semi-permanent or sacrificial (one release/application). A sacrificial type is preferred at this time due to ease of release, low gloss and part-to-part gloss consistency.

3. Coating is applied at 0.8 - 1.2 mils to the top and bottom of the tool (20 - 40 sec.), followed by a 10 - 30 sec. flash, depending on application.

4. A metal insert is placed in the mold and the mold is closed.

5. Two-component PU foam is injected.

6. The tool remains closed for 45 -150 sec., depending on the substrate type (type of blowing agent).

7. The mold is opened and the painted part is removed, trimmed and packaged for shipment to assembly plant.

Advantages of In-Mold Waterborne Coatings

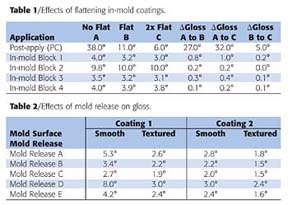

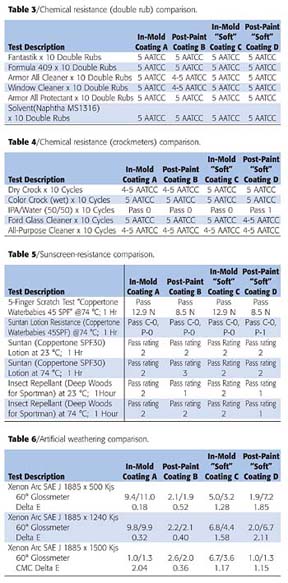

In addition to processing advantages, in-mold coatings offer other advantages over post-painting. Complex part designs can be processed without the worry of part shrinkage, gloss control or marring. The in-mold process with aromatic polyurethane allows the designer to integrate multiple components in the part. This can be a one-piece steering wheel/airbag unit, or an integrated passenger side airbag on spray PU IPs. The parts produced from the in-mold process yield exact duplication of the grain, finish and styling detail of the mold. There is no loss in shape or shrink-back after de-molding due to the fully relaxed state of the polymer in the finished, cured skin. The skin is formed in its desired shape at the time of molding. There is no forming or stretching of the skin, which occurs in the competing process of thermoforming. The thermoforming process causes stretching of the material, which results in a loss of grain definition. It changes the surface tension, which can lead to adhesion problems for the post-paint. Also, delamination often occurs over time due to shrink-back.Most post-paint applications can only achieve low gloss levels by overloading the coating with inorganic fillers. This results in a degradation of film properties such as the coating mar resistance. With in-mold coatings the tool grain and finish can be manipulated to achieve a wide range of gloss levels. Figure 3 shows the effect that the tool grain and finish can have on the final coating gloss. It is possible to achieve a 1-2 gloss by tool/finish design and mold release selection. No manipulation of the in-mold coating by addition of flattening agents or texturing agents is necessary to achieve the desired gloss. Table 1 shows a study in which an in-mold coating was prepared with three different levels of a flattening agent, and then sprayed over four different mold grains, and then post-applied over a polycarbonate panel. This study shows the effects that the grains and flatting agents have on the gloss level.

As can be seen in Table 2, the mold release used can affect the final gloss of the coating by as much as 5°. It should also be noted from Table 2 that the polymer choice for the coating has an effect on the coating gloss and the control of that gloss over different textured or grained surfaces.

The in-mold process is also much better suited for two-tone applications than post-paint applications. With in-mold processes, applying two colors can be performed in the initial painting step with only a slight increase in the processing time.

Film Properties of In-Mold Coatings vs. Post-Paint

Through the proper resin choices, in-mold coatings can be formulated to meet all current interior OEM requirements while maintaining a high degree of flexibility for proper mold release without post-baking. Shown in Tables 3 and 4 are test results comparing two different types of in-mold coatings to their corresponding post-paint coatings. Coating A is a waterborne in-mold lacquer, Coating B is a waterborne post-paint lacquer, Coating C is a waterborne soft, "leather-like-feel" two-component urethane in-mold coating, and Coating D is a waterborne, soft "leather-like-feel" two-component urethane post-paint coating. Table 3 shows a comparison of various chemical resistance tests that were taken from different OEM specifications. These tests show the chemical resistance of the in-mold coatings compared to the post-paint coatings.As can be seen in Table 3, the rub test results for the in-mold coating are equal to or better than the results for the post-paint coatings.

Table 4 shows a comparison of several different chemical crock tests that were taken from different OEM specifications to show the chemical resistance of the in-mold coatings compared to the post-paint coatings. It shows that the crock test results for the in-mold coatings are equal to or better than the results for the post-paint coatings.

Table 5 compares the sunscreen lotion resistance of the in-mold coatings to that of the post-paint coatings. The in-mold coatings have superior lotion resistance as compared to the post-paint coatings for the five-finger scratch test. This is due in part to the spray elastomer itself being more chemically resistant and having a better chemical bonding or adhesive strength at the substrate/coating interface. The ABS or polycarbonate-type substrates have poor chemical resistance to the components in the sunscreen lotion. This allows for substrate swelling and loss of adhesion at the coating/substrate interface due to lower adhesion strength.

Table 6 compares the artificial weathering of the in-mold coatings versus the post-paint coatings. It shows that the performance of the in-mold coatings is comparable to their post-paint counterparts for Xenon exposure and that the chemical and artificial weathering tests perform equal to, and in some cases, better than their post-paint counterparts.

Conclusion

This innovative in-mold coating technology is far superior to traditional post-painting processes in a variety of ways. It provides solutions to many of the shortcomings associated with post-paint systems while delivering a part with equal to, and in most cases, superior coating performance. In-mold coatings deliver all of the advantages from a processing and performance perspective, from an environmental perspective, and it does it all at a lower cost.

Acknowledgements

Special thanks to the team who helped turn this idea into a commercial success:

Red Spot: Marilyn Bara, Mark Lutterbach, David L. Young, Kyle Shane, Paul Morgan, Test Lab Staff.

BASF: Jon Pavlinac, Bill Venier, Mark Ihara, Matthew Varughase, Dave DeBiasi

This paper was presented at the International Waterborne, High-Solids, and Powder Coating Symposium, sponsored by The University of So. Mississippi, Dept. of Polymer Chemistry, February 2005, New Orleans, La.

Report Abusive Comment