Acrylic Latex Paints: Still the Gold Standard for Exterior Performance

Recently, suppliers of other waterborne binders for exterior coatings have mounted a new campaign against the primacy of acrylic latex chemistry.

|

|

For over four decades, properly formulated, top-quality latex paints based on all-acrylic binders have withstood all challenges to their position as the premier architectural finishes in North America. Recently, however, suppliers of other waterborne binders for exterior coatings have mounted a new campaign against the primacy of acrylic latex chemistry. The most interesting aspect of this latest effort is the novel strategy being employed.

Traditionally, manufacturers of alternative binders have routinely maintained that their products deliver the features of all-acrylic emulsions at a lower cost. Now, however, some are acknowledging the historical superiority of all-acrylic binders - and their continuing preeminence on bare wood surfaces - but are claiming that other chemistries have improved to the point where they represent legitimate performance alternatives in exterior applications, so long as they do not involve wood.

The uses specifically targeted by suppliers of alternative binders are non-wood materials - masonry, stucco, brick and metal - that are becoming increasingly popular in new home exteriors. Some providers are insisting that certain binder chemistries - i.e., vinyl acrylic, vinyl versatate (VeoVA), styrene-acrylic and vinyl acetate ethylene (VAE) - offer performance comparable to, or better than, acrylic binders on these substrates, customarily for less money. In the coatings industry, vinyl acrylic and polyvinyl acetate (PVA) are often used imprecisely as synonyms. Strictly speaking, the term PVA applies only to polyvinyl acetate homopolymers. The term "vinyl versatate" (VeoVA) is often used broadly in the paint industry to describe any copolymer that includes VeoVA monomer. For economic reasons, VeoVA homopolymers are virtually never used as paint binders. Consequently, most so-called VeoVA binders are actually copolymers of VeoVA and a less costly monomer, vinyl acetate (VA) in particular. The VeoVA products mentioned in this article are all VA/VeoVA copolymers. In support of the above assertion, the suppliers point to the popularity of styrene-acrylic and VeoVA paints in Europe and Asia, where masonry materials have been used much more extensively than wood on home exteriors for decades.

The case for "nonacrylic'" (that is, binders not composed completely of acrylic monomers) binders in high-performance exterior paints is plausible. There has been a shift in new housing construction to a greater use of non-wood substrates. Many of these popular materials do have greater dimensional stability than wood and so do not require the unmatched grain-crack resistance that all-acrylic binders provide. Hence, there is the possibility that paints formulated with nonacrylic binders may be as or more appropriate than all-acrylic latex paints for these non-wood exterior substrates.

What the proponents of nonacrylic binders do not provide is documentation for their main premise: that other chemistries offer advantages over all-acrylic binders on non-wood substrates. It is, therefore, worthwhile to revisit the issue of exterior paint performance on these types of surfaces.

|

Special Performance Requirements of "New" Housing Materials

Any comparison of exterior binders used in coatings designed for the new wave of housing materials needs to first identify the properties these substrates demand from a finish, especially the attributes not required in coatings applied to wood. As we have indicated, most of these materials - brick, stucco, fiber cement, cinder block - belong in the general category of masonry, so we will focus on the features that masonry requires. The term "masonry" means different things to different people. This article employs the word in a broader sense to indicate any cement-based construction material. A representative but by no means comprehensive list of masonry substrates would include concrete, mortar, cement shingle, cinder block, brick and stucco.

From the standpoint of finishes, the key difference between masonry and traditional wood substrates is that the former tend to be highly alkaline when fresh, or when damp or wet from the intrusion of water, and they are prone to efflorescence. Many masonry surfaces are also vulnerable to the development of fine surface cracks. These anomalies constitute a special problem that cannot adequately be addressed by standard thin-film architectural coatings in climates that experience wide temperature fluctuations. Applications such as these typically require the use of functional elastomeric wall coatings (EWCs) applied in thick films (12 to 20 dry mils) to bridge the surface cracks. Historically, not all nonacrylic binder chemistries have been able to accommodate these masonry characteristics.

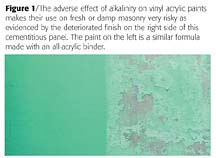

The limitations of vinyl acrylic binders in this regard have been well documented. Latex paints based on vinyl acrylic emulsions are notoriously unable to cope with high alkalinity (pH³9). When they are applied to fresh masonry, the combination of high pH and ambient water can hydrolyze the vinyl acetate portion of the binders, causing the coating films to deteriorate badly (Figure 1). The adverse effect of alkalinity - "alkali burn" in paint vernacular - on vinyl acrylic paints makes their use on fresh masonry very risky. Only when enough time has passed for the masonry to become more neutral - as long as a year or more - can they be used reliably. Alkali burn can also be a problem later in the life of the coating if water from the soil or air manages to penetrate the masonry in some way (hydrostatic pressure, cracks or faults in the construction, breaks in the coating, etc).

Coatings based on other types of nonacrylic binders have also been vulnerable to alkali degradation, although to a lesser degree than vinyl acrylic formulations. The one proven exception has been styrene-acrylic binders, although VeoVA products are also purported to be excellent in this regard. Indeed, as indicated previously, VeoVA emulsions are now being promoted by some as the performance standards in this area.

The situation has been different in the case of efflorescence resistance. Despite claims that VeoVA polymers are superior in this regard, none of the popular nonacrylic binder chemistries has offered any general advantage or disadvantage in the area of efflorescence. Instead, the property has been related more to individual binder design (and to some degree, the nature of the paint formulation). There have been polymers of every type that offer efflorescence resistance; there have also been products of every type that do not.

Of course, the fact that there are differences among individual nonacrylic binders in their ability to provide alkali and efflorescence resistance is really not the issue. The ultimate concern is rather whether any or all of these chemistries have evolved to the point where they are now generally better than - or, at least comparable to - all-acrylic chemistry in their ability to provide these features.

Testing is by no means complete in this area, but much of the laboratory test and exposure trial data generated to date suggests the contrary: that all-acrylic binders remain unsurpassed in this respect. Comparisons of paints based respectively on VA/VeoVA emulsions (the supposed new benchmarks for alkali resistance) and all-acrylic binders are particularly revealing. Studies conducted at Rohm and Haas confirm that the VA/VeoVA binders do provide better alkali resistance than vinyl acrylics. But they also indicate that the VeoVA products do not approach the standards set in this regard by high-performance all-acrylic binders in properly formulated paints.

The superior alkali resistance provided by all-acrylic chemistry is dramatically evident in a representative exposure study comparing high-quality (35% PVC, 36% VS) sheen paints applied to unsealed fiber cement panels. The different versions of the test paint in this study were formulated with various exterior binders, including commercial and experimental VeoVA emulsions and a proven all-acrylic product. Two coats of the different formulations were applied to sections of the highly alkaline test panels and allowed to dry, after which they were placed on an exposure fence in a north vertical position. In each case, the paint formulation based on the all-acrylic binder was applied to the section at the extreme right edge of each panel to serve as a control. After two years of exposure, the all-acrylic finish has tolerated the highly alkaline surface much better than all of the VeoVA-based paints (Figures 2 and 3).

|

The Question of Exterior Durability

Clearly, in paints applied to fresh masonry surfaces, all-acrylic binders continue to offer significant advantages over most alternatives. Well then, what about non-wood substrates where alkalinity and efflorescence resistance are not critical requirements: weathered masonry and metal, for example? We already know that grain cracking does not occur on these dimensionally stable substrates. Would finishes based on nonacrylic binders be legitimate alternatives to all-acrylic latex paints in these types of applications?

The enthusiastic endorsements for the nonacrylic binders would certainly lead the potential user to think so. The problem is that many of the claims made for these emulsions are based on a simplistic conception of exterior performance.

In establishing the exterior capabilities of their binders, advocates generally cite one or two aspects of performance in which nonacrylic binders are judged to be comparable or superior to all-acrylic emulsions. VeoVA emulsions are characterized as providing better scrub resistance, better water resistance and less odor. Vinyl acrylic binders are supposed to match the all-acrylic emulsions in gloss and tint retention. VAE products are acclaimed for scrub resistance. Styrene acrylics are promoted for gloss, chemical resistance and dirt pickup resistance.

The exterior performance claims for the nonacrylic binders raise two issues. For one, some of the features claimed have little to do with exterior performance. Scrub resistance, for example, is an appropriate concern in interior paints, but it is not particularly meaningful for paints used outdoors. Odor is not really a performance issue for any paint, and, as with scrub resistance, is generally considered an interior rather than an exterior property.

Second and more important, even if the various nonacrylic binders were each equal or superior to all-acrylic emulsions in one or two areas of exterior performance - a fact not at all certain - that edge would not necessarily make them equivalent or better over-all exterior binders. The ultimate measure of any exterior coating is durability - or more precisely, decorative durability - that is, how it retains its appearance on exposure. Decorative durability refers to a paint's ability to retain its aesthetic appearance on exposure to the elements. It is different from protective durability, which refers to the paint's ability to shield a substrate. It is entirely possible for a paint to simultaneously display good protective durability and poor decorative durability. To perform well outdoors, a paint film must possess a variety of attributes: 1) it should retain its gloss and color; 2) it should adhere well, particularly to old, weathered paint; 3) it should resist chalking; 4) it should be able to tolerate the movement of dimensionally unstable substrates without cracking; 5) it should not attract dirt; and 6) it should not be excessively vulnerable to mildew growth. As we have indicated, some exterior surfaces are very stable dimensionally and so do not require resistance to cracking, but the other attributes are more or less obligatory in all applications.

|

Exposure Test Results

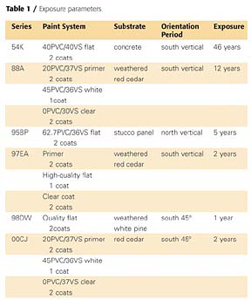

The only legitimate way to evaluate different emulsions' relative merits as exterior binders is to monitor their overall performance in exposure tests. For that reason, paint manufacturers are continually conducting trials of these products in all types of paint formulations, on all types of substrates, under all types of conditions (see sidebar on page 31). Significantly, as in the cases of alkali resistance and efflorescence resistance, none of the data from exterior studies reported to date support the idea that nonacrylic binders have achieved overall superiority or even parity with all-acrylic emulsions in the area of durability. The following sections contain photographs of representative panels from exposure trials conducted by Rohm and Haas (exposure conditions in Table 1). No matter what the alternative binder, the type of test paint, or the substrate in these performance comparisons, formulations based on all-acrylic binders are demonstrating clear durability advantages.

|

Acrylic Versus Vinyl Acrylic

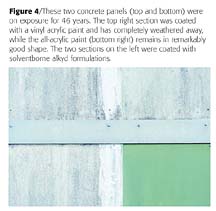

Latex paints formulated with vinyl acrylic emulsions have never been able to match all-acrylic formulations in terms of durability. Even before the advent of polymers designed specifically for exterior use, the inherent superiority of all-acrylic to vinyl acrylic chemistry in this respect was evident (Figure 4).

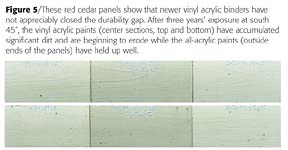

Recent exposure studies indicate that newer vinyl acrylic binders have not appreciably closed the historic exterior durability gap. Series 00CJ (Figure 5) provides strong proof of this point. In this series, red cedar panels containing three undercoats of acrylic latex paint (two coats of primer and one flat white coat) were covered with two clear topcoats formulated with various binders and placed on south 45º exposure. After approximately three years on the exposure fences, two panels containing topcoats formulated with vinyl acrylic binders clearly reveal the superiority of the all-acrylic control paints. While the all-acrylic paints on the outside ends of the panels have tolerated harsh, south 45º exposure extremely well, the vinyl acrylic paints (Paints 4 and 5 respectively in the middles of the panels) have accumulated significant amounts of dirt and are beginning to erode.

Acrylic Versus VAE

On balance, VAE emulsions offer similar exterior performance to vinyl acrylics; in other words, they do not match the durability of high-performance all-acrylic binders. Specific problems experienced by paints based on VAE include efflorescence (Figure 6 - Series 95BP) and actual disintegration of the coating film (Figure 7 - Series 00CJ). Both of these conditions have manifested themselves on relatively short term (five and three years respectively).

Enlarged image

|

Acrylic Versus Styrene-Acrylic

As indicated previously, the use of small amounts of styrene in a polymer can offer useful benefits in the areas of gloss, hydrophobicity and dirt pickup resistance. The downside is that the styrene monomer is not as inherently resistant to ultraviolet radiation as acrylic monomers. Consequently, paints based on styrene acrylic binders have a much greater tendency to fade, yellow and chalk than their all-acrylic counterparts.

Two exposure series, 97EA (Figure 8) and 00CJ (Figure 9), illustrate some of the exterior performance limitations of styrene-acrylic chemistry. In 97EA, both all-acrylic topcoats are performing well although they have experienced a slight degree of dirt pickup. The styrene-acrylic paint, however, has experienced catastrophic failure under the same conditions. In addition to accumulating large quantities of dirt, the paint film has cracked and yellowed badly. The styrene-acrylic formulations (Paints 6 and 10) being evaluated in Series 00CJ show a similar pattern of inferior durability. Both styrene-acrylic paints have picked up considerable amounts of dirt and are beginning to show mottling that suggests erosion of the paint film.

Acrylic Versus VeoVA

Previously, we had indicated that Rohm and Haas studies do not support VeoVA claims for superior water and efflorescence resistance; our exposure data also demonstrate that paints formulated with VeoVA binders are vulnerable to the accumulation of airborne dirt. In Series 88A, a clear VA/VeoVA formulation (Paint 9) is particularly deficient in this respect (Figure 10). A newer set of exposures - 00CJ - shows the same pattern (Figure 11). As with its relative in the older exposure series, the VA/VeoVA paint in Series 00CJ (Paint 9) is revealing itself extremely prone to dirt pickup.

Acrylic Versus Blends

Some manufacturers have recognized the superior performance afforded by acrylic chemistry and have attempted to upgrade less-durable emulsions by blending them with acrylic polymers, particularly in an effort to improve adhesion. Film coalescence problems inherent in this practice generally make it less beneficial than hoped for as Series 98DW (Figure 12) and 00CJ (Figure 13) show.

Exposure Series 98DW shows the detrimental effect of blending on dirt pickup. In this case, the two paints at either end of a panel were based on a vinyl acrylic (Paint 1) and an all-acrylic binder (Paint 5), respectively. The paints in the middle sections of the panels were formulated with blends of the two binders. Paint 2 was based on a 75/25 vinyl acrylic/acrylic blend; in Paint 3, a 50/50 blend; and Paint 4 a 25/75 vinyl blend. Only the all-acrylic formulation has exhibited acceptable dirt pickup resistance. In Series 00CJ, coatings based on two different vinyl acrylic/acrylic binder blends (Paints 12 and 13) exhibit the same kind of performance problems as products in Series 98DW.

Conclusion and Summary

Sometimes, it really is true that the more things change, the more they remain the same. Contrary to the claims being made by the manufacturers of nonacrylic binders for latex coatings, all-acrylic emulsions remain the gold standard for any exterior house paint, regardless of the surface being coated. Not only do the all-acrylic emulsions offer all the alkali and efflorescence resistance required by many of the masonry materials that are popular in new housing construction, but they continue to provide a better overall balance of exterior performance properties than any competitive waterborne binder chemistry.

For more information, contact Andy Crane at ACrane@rohmhaas.com.

The Need for Realistic Testing

There is a perspective sometimes overlooked or ignored in testing exterior paints. In many cases, a test paint product may perform quite acceptably if it is applied exactly in accordance with label directions. Complete and proper testing, however, should also assess performance under more adverse conditions, such as application to wood without benefit of a primer, application to chalky surfaces, application in a thinner-than-ideal film, and application when the temperature is lower than it should be. Paint manufacturers want to minimize the chance of failures and claims with paint jobs not done completely "according to directions," and testing that incorporates realistic application practices has demonstrated that quality all-acrylic binders provide manufacturers with "insurance" against problems in this regard.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!