Immersion Milling Quick and Easy

Many articles have been written by several mill companies claiming their basket mill to be superior, playing off of what they believe to be shortcomings in other "immersion"- or "basket"-type mills. They contend that immersion mill technology is best suited for small-batch processing and low-viscosity and easy-to-grind products. I would suggest they do not understand or do not want you to understand immersion milling technology. Their contention is that only a horizontal mill is suitable for high-solid, high-viscosity, hard-to-grind pigments and particles that require transfer pumps, tanks, hoses, and mechanical seals.

Our immersion mill uses circulation-milling technology (the same concept as used in the new high-circulation horizontal mills) by rapidly pumping the slurry through the media field many more times and more efficiently than any other mill, including horizontal or vertical mills. Remember that any external mill (horizontal or vertical) that relies upon tank-to-tank or same tank re-circulation is not a continuous process but a batch process.

I have wondered why our industry still makes the process of grinding and dispersion, or "milling," so difficult. Several basket mill manufacturers have added 2nd and 3rd mixing shafts to their basket design. Why? Because their basket designs have low exit velocities, a byproduct of poor throughput. Without the use of a bottom suction device directly below the basket, the slurry bypasses the bottom of the media field (the high energy zone) following the path of least resistance through the side screen. Without it, any product higher than a few hundred centipoise in viscosity will be motionless within a few inches of the basket, and the result is stratification in the milling process. (A similar phenomenon known as short cycling occurs in horizontal mills when the slurry follows the wall of the grinding chamber to its discharge rather than work against the centrifugal force of the media.) This doubles and sometimes triples the time required to reach product quality and results in wide particle size distribution within the slurry.

The addition of agitation alongside of the basket improves flow around the basket by creating side vortices in the tank. However, this simultaneously pulls slurry away from the mill entry and into the side vortexes, creating the illusion of rapid batch turnover through the mill. Although the side vortexes partially compensate for the poor flow characteristics of a side only or bottom only screen discharge, they do little to improve milling time or performance. The side positioned agitation blades produce a combination of suction and backpressure against the discharge area, canceling any potential benefit in flow through the screen.

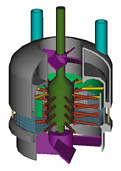

The solution to the problem is a dual draft tube (HEC Patent) top and bottom with a bottom screen in addition to the side screen and a suction device (pumper blade) positioned within the bottom draft tube below the bottom screen. The blade in the lower draft tube focuses the suction of slurry exclusively from the mill's upper level. "Bypass" through the side screen is greatly diminished as a greater percentage of slurry is drawn deeper into the bead field or high energy zone before reaching the side or bottom screen discharge. The rapid, uniform flow of slurry drawn down through the top and outward toward the bottom of the mill increases batch throughput rate by 50%. Performance is increased 20% more when a top propeller is mounted within the draft tube above the bead field to force feed the mill when viscosities are above 15,000 cps. (This also eliminates the need for additional motors, shafts, etc., to drive the supplementary agitators.)

The Hockmeyer HSD Immersion Mill is efficient and versatile, and is available to operate in batch sizes from 750 mL to 5,300 L. Its proven design can out-perform horizontal, vertical or other basket-type media milling systems by 30-300%. The basic machine consists of a highly polished, water-cooled, submersible basket with side and bottom screens and upper and lower draft tubes. Within the basket is a rotating hub with pegs and a removable (HEC Patent) counter-peg assembly. Top and bottom pumping impellers work together to enhance the flow of the dispersion through the bead field in the basket. To accommodate different viscosity ranges, three styles of lower impellers are available for acceleration of the flow inside and outside the basket (mild/moderate/ aggressive).

The design requires a bottom support bushing (some see this as a weak point but it is one of our strong points when considering all the benefits) to accommodate the lower concentric pumper blade. The bushing is available in Rulon (a PTFE-based thermoplastic with a high pressure velocity rating and that is resistant to most solvents) or ceramic composition depending on the application. The bushing is simple, quick to replace and inexpensive. Most applications require replacement only once a year and the change normally takes less than an hour to accomplish. The mill can be completely disassembled and reassembled with a fresh charge of media within that same time period when required.

The performance difference is so great, the immersion mill is the "Ideal Mill Design" and offers the following advantages.

- Rapid mixing and milling of raw materials are completed simultaneously in one tank engaged for the entire cycle. In some cases there is no benefit to premixing on a disperser (mostly viscosity and application dependent). The machine is designed for use in multiple tanks with various capacities.

- Multiple tank positions with 360-degree rotation.

- Minimization of contamination, clean-up, solvent loss and product loss.

- Maximization of color strength, gloss durability and yield.

- Reduction of process time by an average of 30-300%.

- Reduction of raw material costs by an average of 5%.

- Highly efficient uses of small quantities of media.

- Use media as small as .25 mm and as large as 2 mm.

- Consistent and predictable performance.

- Various materials of construction available

For more information on immersion mills, contact Hockmeyer Equipment Corp., 6 Kitty Hawk Lane, Elizabeth City, NC 27909; phone 252/338.4705; fax 252/338.6540; visit www.hockmeyer.com; e-mail sales@hockmeyer.com; or Circle Number 142.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!