Pigment Dispersions Using Sonic Techniques

One of these methods provides a means for material to be in direct contact with high-energy cavatational forces. It does not involve high electrical energy or a complicated generating mechanism. This method provides a means for high-intensity processing of very large amounts of materials economically by a direct translation of kinetic energy produced in a pump into cavatational energy ultrasonically produced. Created in tandem along with high-pressure homogenization, this system provides complete and instantaneous emulsions and dispersions, perfect for those applications requiring high-intensity mixing.

Appropriate for both liquid-liquid applications and liquid-solid (emulsions), the material is pumped through a specially shaped orifice at high velocity of 300 feet per second or more, forming a flat stream. The jet of material then impinges on a knife-like blade, which creates waves or vortices of ultrasonic energy running perpendicular to the flow. The pressure drop created by the orifice and the ultrasonic cavatational forces combine to create a high-energy mixing effect. Pressures starting at 200 psi to as high as 5000 psi with flow rates up to 250 gal/min or greater are possible.

Detailed evaluation of the phenomena occurring in the region of the blade shows that a vibration tends to set up, forming a cavity more rapidly than the liquid can fill, essentially stretching the liquid. Dissolved gasses in the liquids will relieve this stress by forming bubbles that expand very quickly. One twenty thousandth of a second later the bubble collapses. This alternating expanding and collapsing develops a pressure differential shock wave that has been measured as high as 500,000 psi. When dissimilar liquids are passed through this cavatational field, fine-particle-size emulsions are formed. If finely divided solids are passed through the system, dispersion of solids tends to take place.

Along with laboratory testing for determining the optimum operating pressure, there are two ways of adjusting the energy being produced. One is the blade to orifice distance, which leads to generation of maximum acoustic energy. The optimum location will vary with temperature, viscosity, thixotropy of the system, density, as well as the nature of the system itself. The other parameter is related to the backpressure. If a small amount of backpressure is imposed down stream of the orifice, acoustic energy is increased substantially. There are also different Sonolator designs, each built to address different flow rates and pressure requirements.

Applications in Coating Systems

Sonolation has been applied successfully to a wide variety of products produced by the paint industry. Achievements are related to improved level of dispersion or substantial economic savings, usually reduced manpower, processing time or both.Interests in the coatings industry are becoming broader and extend beyond traditional paint manufacturing and into other potential coatings arenas. These applications include polyester resin fiberglass systems, including gel coats, casting of methacrylates, electrocoating of metal parts, etc.

The balance of this report will be devoted to presenting some of the systems and the special contribution Sonolation has to make. Since many of these systems are more or less unique, at least in the eyes of the manufacturer, we will not bore you with tables of data and formulations, but restrict our remarks to the general descriptions of the process involved.

Polymer-Based Systems

Silica Gel Dispersion in Polyesters

A growing application area is that of polyester polymers in reinforced fiberglass structures for fabricating tanks, structural and decorative panels, etc. In order to manufacture these polymers efficiently and effectively, the viscosities must be increased in order to prevent the run-off during hand lay up. Finely divided colloidal silicas usually provide thixotropic properties. These silica additives tend to agglomerate and settle out, giving the polyester uneven viscosity build up and poor uniformity. High-intensity mixing is required to give the material homogeneity, and the use of Sonolation has provided an economical means of providing this high-intensity energy. A rough pre-mix can be passed through the Sonolator once, providing good uniformity. A simply designed system at low capital investment is capable of operating at high-capacity throughputs.Polymer-Based Systems

Silica Gel Dispersion in Polyesters

A growing application area is that of polyester polymers in reinforced fiberglass structures for fabricating tanks, structural and decorative panels, etc. In order to manufacture these polymers efficiently and effectively, the viscosities must be increased in order to prevent the run-off during hand lay up. Finely divided colloidal silicas usually provide thixotropic properties. These silica additives tend to agglomerate and settle out, giving the polyester uneven viscosity build up and poor uniformity. High-intensity mixing is required to give the material homogeneity, and the use of Sonolation has provided an economical means of providing this high-intensity energy. A rough pre-mix can be passed through the Sonolator once, providing good uniformity. A simply designed system at low capital investment is capable of operating at high-capacity throughputs.Pigment Dispersion in Acrylic Systems

The market in resins and plastics, which has attracted some paint manufacturers, is the casting of acrylic sheeting. Here, proper color dispersion is very important, especially in the display sign industry. Cavatational energy, as provided by the Sonolator, provides excellent result at very low cost by improving the dispersion of the ultimate size pigment particles. This is a simple and rapid technique where the pigment is wetted out in a mixture of plasticizer, monomer and polymer, and then pre-mixed, diluted to a final desired concentration and then Sonolated for one half hour on a recirculation loop. An 8- to 10-hour process is reduced to 30 minutes. Pigment dispersion is improved to the extent of reducing rejects dramatically. The Sonolator pump is then used to transfer the finished dispersion to holding tanks or storage. The metering devices and closed-loop pipe work make the process clean, rapid, economic and virtually automatic.

Color Development in Coatings

When manufacturing color-pigmented products involving dispersing solids within a liquid, the system may be susceptible to color drift caused by pigment flocculation. These problems stem from tinting color incompatibility in pigmented bases or incompatibility with the polymer systems. This may also be related to incomplete wetting out of pigments caused by adsorption of air on pigment surfaces, which is not completely eliminated during dispersion.It is known that cavatation has a deaerating effect. In the case of Sonolation, passing incompletely wetted pigments through the cavatational envelope probably results in elimination of adsorbed gases from pigment surfaces, thus providing the route for complete wetting. By that same mechanism, flocculated polymers or other incompatible combinations tend to be deflocculated and blended thoroughly. The Sonolator has been used successfully in four different ways to develop color fully: by continuous processing of paint and addition of tinting colors; by redispersion of flocculated paint constituents; by processing finished paint to complete deaeration of the pigment; and by the production of fines in tinting concentrates.

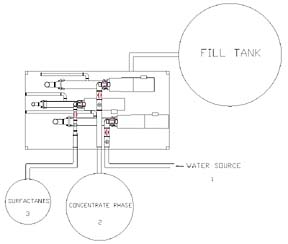

An economical processing system can be set up whereby the paint to be tinted is charged into one tank and the tinting color charged into a second. The paint is recirculated in its part of the system while the tinting color is injected through a feed valve into the Sonolator with the recirculated paint. This method of tinting color addition yields a completely dispersed color with no flocculation and, by creating the maximum number of fines, yields paint with color fully developed.

Trade Sales (Architectural) Paint

Data developed from all of these systems indicates that cavatation energy is able to de-agglomerate flocculated pigment particles of the type used in most trade sales paints. Sonolation tends to deaerate liquid systems. On pigments being wetted out, adsorbed air on pigment surfaces is de-adsorbed and surfaces are wetted rapidly and completely. The preferred technique calls for addition of pigment to solvent in a typical make-up tank with Sonolation provided in a recirculation loop in the presence of only a small percentage of resins in order to keep viscosity low and enhance the rate of wetting out. After deagglomeration has been complete, the balance of the polymer formulation and other additives can be made rapidly and the batch completed in the same make-up tank while colors are fully developed. Sonolation represents a rapid, simple method of speeding up the rate of paint manufacturing without the addition of complicated, high-cost equipment. Power requirements are low, and the simplicity of the equipment provided for quick and easy cleanup.Aqueous Systems

Electrocoating

As in other systems, Sonolation has found acceptance in areas such as electrocoating paint systems. In this process, a system similar to the electroplating of metals is used. A dip tank is filled with paint and an electric field is used to promote the deposition of a coating material onto the part. The part being painted acts as an electrode that is oppositely charged from the particles of paint in the dip tank. This process ensures complete coverage along with uniform film thickness and good adhesion. Electrocoating requires very careful control on two counts.- The level of solids must be held constant, being replaced constantly at the same rate as they are removed.

- Replacement solids are usually provided in the form of a concentrated paint, which tends to flocculate and lump, settling in the dip tank or adhering to the object being painted, giving a non-uniform appearance and thus causing rejects. The regenerating system must be able to add solids continuously and in a finely dispersed form.

Developing the Viscosity of Thickeners

In most waterborne systems, thickeners such as methylcellulose, carboxy-methyl celluose, etc., are used for viscosity control. Complete swelling and solution of some of these thickeners is usually time consuming. Often the time required to accomplish this step is the longest single operation in the entire process. Under the influence of high pressure and ultrasonic cavatation, these particles, which are swollen in water, are quickly dispersed so that the swelling takes place in a very short time span, shortening the total processing time dramatically.Latex Emulsions

Although easy to make by established conventional methods, latex paints require careful preparation of constituents in a selected order of addition. First, pigments are dispersed in water with wetting agents, antifoaming agents and other additives found in the formula. Titanium dioxide pigments are usually dispersed first and then the extender pigments added. In many cases the order and rate of addition of these pigments is critical. A long period of time is consumed using high-speed mixing equipment in order to complete the wetting out and dispersion process. Latex emulsion is then added, accompanied by a much lower level of mixing energy in order to avoid coagulation or breaking of the latex emulsion. Thickeners may then be added to bring the viscosity of the finished product up to the proper level. Predispersion of these thickeners is usually done separately. This entire operation requires careful control, and is usually accompanied by problems like foaming, aeration, incomplete wetting out of pigments, etc. Color development may not be complete because high levels of work (mixing) cannot be accomplished once the latex is added.

Sonolation has shown that a good deal less attention is needed to complete wetting out of pigments, order of addition of materials, etc. Thickening agents can be pre-dispersed in the same equipment. Once a rough pre-mix has been brought together and pigments coarsely dispersed, circulation through a Sonolator provides complete development of the finished product properties. Latex emulsions have not been broken in such treatment. Since the Sonolator system is closed, no aeration or foaming problems occur. The Sonolator offers techniques that permit less labor, shorter batch cycles and simpler formulation procedures. Substantial production capacities are possible with little capital investment.

Other Waterborne Systems

Waterborne polymer systems, other than latex emulsions, involve the dispersion of various types of polymers. This lends itself naturally to Sonolation for the development of small polymer particle size as well as the optimum dispersion of pigments. The dual-feed scenario in which an oil phase and water phase are metered together in a balanced manner, with the pigment dispersion following or proceeding, provides an economic advantage for the paint manufacturer.Summary

Utilization of high-pressure ultrasonic cavatation represents an efficient and simple form of high-intensity mixing. Other devices such as impact energy generated in piston homogenizers or high-shear energy from colloid mills or other mill types usually require high-energy input, capital investment and maintenance costs. In most instances, processing procedures are limited to batch-style operations. Very often, a good deal of energy is lost in friction, resulting in excessive heating.Sonolation provides high-intensity mixing at any given throughput. Flow rates can be adjusted to meet the flow rates of other machinery such as filing equipment. Most any job can be performed in a single pass, offering faster processing or more complete processing. Steps that have taken several hours are now reduced to much shorter times.

Multiple-feed offers a whole world of processing efficiencies, allowing for even more efficient use of existing tank space by increasing throughput without adding more tanks. Since the Sonolator operates solely with pressure as its energy source, scalability from the lab to production is simple and seamless. The same goes for repeatability. Simply maintain the optimum pressure and you will get the same results time after time, also reducing your potential for waste.

A Sonolator system is very easy to clean and inexpensive to maintain. It can be disassembled, cleaned and reassembled in less than 10 minutes. The commercially available pump and motor are essentially the only moving parts, offering low maintenance costs and low power consumption. A system is easy to automate with a simple PLC. You can monitor and control optimum pressure, flow rate and call for more materials from secondary vessels or tanks.

Sonolation offers a path toward increased plant capacity with very little capital investment; an investment that should be able to be recouped rapidly in lower labor requirements, shorter batch cycles and simplified processing techniques.

For more information, contact Sonic Corp., One Research Dr., Stratford, CT 06615; phone 203/375.0063; e-mail kurt.limbacher@sonicmixing. com; or visit www.sonicmixing.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!