Raising Profits With Bead Mills

Courtesy of Buhler Inc.

Courtesy of Buhler Inc.

Courtesy of Buhler Inc.

Courtesy of Buhler Inc.Higher Throughputs

It is well known that an obsolete line of equipment requires more maintenance, resulting in more frequent, and longer, downtimes. Machine wear is also higher, which further increases costs. The large grind chambers of old bead mills lead to considerable loss of valuable product, cross-contamination and increase costs related to disposal of cleaning materials. Courtesy of Buhler Inc.

Courtesy of Buhler Inc. Courtesy of Buhler Inc.

Courtesy of Buhler Inc.Higher Viscosities

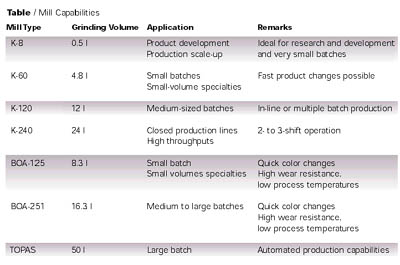

The conical shape of the K-series grind chambers enables these mills to efficiently process medium- to high-viscosity mill bases. Centrifugal acceleration of media developed by the mills reduces the load on the gap separator eliminating nuisance shut downs due to packed media. Higher viscosity milling enables higher pigment concentration in the mill bases. This reduces the volume of mill base required to produce a batch, which leads to more efficient, lower cost production. Courtesy of Buhler Inc.

Courtesy of Buhler Inc.Fast, Reliable Product Development

Changes in the marketplace call for constant adjustments to formulations and the development of new products. The new K8 laboratory bead mill enables fast, lost cost product development and reliable scale-up parameters to production equipment. The mill matches the conical production machine geometry and uses the same size grinding media as production equipment. In addition, automated data acquisition of key process parameters is also provided. Courtesy of Buhler Inc.

Courtesy of Buhler Inc.Increased Wear Resistance

Advanced developments of ceramic materials allow them to be used at reasonable costs in the manufacture of media mills. Significant properties of ceramics include high wear resistance and excellent heat transfer (four to six times greater than steel) and very good corrosion resistance.Advanced ceramics are used to construct the rotor and stator elements of the BOA/TOPAS series of mills. The full ceramic construction of the process zone enables cost-effective milling of waterborne coatings and grinding of abrasive pigments. High heat transfer enables process temperatures to remain below 50ºC, while achieving quality in a single pass. Product graying and contamination are hardly measurable because of the excellent wear resistance.

Conclusion

To stay ahead of the competition, manufacturers need cost-effective, optimized equipment that reduces current operating costs and also enables development and production of products based on new raw materials. Buhler bead mills offer optimized grind chambers and advanced material of construction that can enable the customer to achieve these goals.For more information on mixing equipment, contact Buhler Inc., PO Box 9497, Minneapolis, MN 55440-9497; phone 763/847.0377; fax 763/847.9911; e-mail kerstin.grosse@bmin.buhler.ch; visit www.buhlerusa.com.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!