New Pigments Enable Use of Dark Colors Without Heat Buildup

Often called “cool paints,” these pigments are

designed to provide a specific color in the visible light range while

reflecting incident light in the near-infrared (NIR) range of the spectrum.

Traditional dark coatings on roofs, car interiors and other exposed surfaces can absorb heat to extreme levels. This excessive heat can lead to product failures, increased energy costs, and an unsafe environment for people.

But manufacturers do not have to resort to only using light colors. Innovative coating pigments have been developed, making it possible for dark surfaces to absorb far less heat despite their color. Coatings using these pigments can be applied to metal with the coil coating process before a product is formed, streamlining the process for manufacturers.

Often called “cool paints,” these pigments are designed to provide a specific color in the visible light range while reflecting incident light in the near-infrared (NIR) range of the spectrum. Depending on the pigment selected, between 30 to 45 percent of the total incident solar radiation gets reflected back into space, compared to just 5 percent for carbon black, the standard black pigments. The lower amount of absorbed energy means surfaces stay cooler, up to 100 degrees Fahrenheit in some applications. Since these new pigments still swallow up the visible light completely, to the human eye, their appearance remains dark.

Cool paints can even lead to a reduction in the dangerous environmental phenomenon known as the Urban Heat Island effect. The Urban Heat Island effect happens in urban areas where black roofs, asphalt and buildings absorb more heat than the surrounding landscape, leading to a harmful cycle of higher temperatures, smog and increased energy demands.

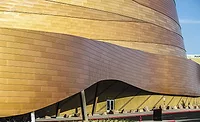

There are hundreds of uses for cool paint pigments on coil coated metal. From cool metal roofs, overseas shipping containers, building facades, and more, metals prepainted with cool coatings are helping to reduce energy costs, increase product lifecycles and increase comfort.

For more information on cool pigments or converting to prepaint, contact a service center or coater that can answer your questions and fulfill your needs at www.coilcoatinginstitute.org/supplier.

Traditional dark coatings on roofs, car interiors and other exposed surfaces can absorb heat to extreme levels. This excessive heat can lead to product failures, increased energy costs, and an unsafe environment for people.

But manufacturers do not have to resort to only using light colors. Innovative coating pigments have been developed, making it possible for dark surfaces to absorb far less heat despite their color. Coatings using these pigments can be applied to metal with the coil coating process before a product is formed, streamlining the process for manufacturers.

Often called “cool paints,” these pigments are designed to provide a specific color in the visible light range while reflecting incident light in the near-infrared (NIR) range of the spectrum. Depending on the pigment selected, between 30 to 45 percent of the total incident solar radiation gets reflected back into space, compared to just 5 percent for carbon black, the standard black pigments. The lower amount of absorbed energy means surfaces stay cooler, up to 100 degrees Fahrenheit in some applications. Since these new pigments still swallow up the visible light completely, to the human eye, their appearance remains dark.

Cool paints can even lead to a reduction in the dangerous environmental phenomenon known as the Urban Heat Island effect. The Urban Heat Island effect happens in urban areas where black roofs, asphalt and buildings absorb more heat than the surrounding landscape, leading to a harmful cycle of higher temperatures, smog and increased energy demands.

There are hundreds of uses for cool paint pigments on coil coated metal. From cool metal roofs, overseas shipping containers, building facades, and more, metals prepainted with cool coatings are helping to reduce energy costs, increase product lifecycles and increase comfort.

For more information on cool pigments or converting to prepaint, contact a service center or coater that can answer your questions and fulfill your needs at www.coilcoatinginstitute.org/supplier.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!