Milling-Media Review: Part 4

Bead Milling Operating Parameters – Part Two

In the last Milling-Media Review (PCI, March 2009), we introduced some of the parameters and considerations necessary for operating agitator bead mills. For this issue, we continue with the same theme, focusing essentially on the nature and significance of the feed materials and their effects on the overall milling process.

|

| Figure 1 Click to enlarge |

Operating Parameters

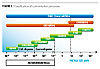

As a first step, it is important to review the scope of activity for agitator bead mills and detail, to some degree, the physical nature of the materials processed. Figure 1 gives an overview of the general field of comminution. It can be seen that agitator bead mills tend to operate in the range from approximately a few hundred microns down to nanometer sizings.

The feed materials vary considerably from industry to industry, however some of the basic concepts are common to all. Material hardness, size and density are all critical considerations, but equally important is the nature of the particles themselves – whether they are primary particles, aggregates or agglomerates (Figure 2). All of these factors have significant bearing on the required milling process.

|

| Figure 2 Click to enlarge |

Process Requirements

The requirement to reduce particle size or disperse materials is necessary in many industries to enhance and improve the final properties of particular products. The actual targets can vary significantly from industry to industry. In the paint and ink industry for example, it can be optical characteristics, gloss/transparency, etc. In other industries, it may be a purely physical consideration, such as the development of active surface area for ceramic processing. A good example to review is the development of color intensity; this is usually determined by the median particle size of the product. The graph in Figure 3 details the intensity development of a particular color with the median particle size D50.

|

| Figure 3 Click to enlarge |

The actual effects can be seen on Figure 4 where a micrograph of the pigment particles size is shown next to the pigment color produced. The level of achieved grind obviously greatly affects the final quality of the product. The nature of the feed material and the target condition are important considerations for the milling process.

Comminution and Deagglomeration

|

| Figure 4 Click to enlarge |

Comminution – True comminution is the grinding of primary particles into smaller sizes. This process requires sufficient energy to break the structural bond of the material itself.

Deagglomeration – Deagglomeration is the breaking of agglomerates or aggregates into primary particles in order to disperse the particles in the medium. This requires only sufficient energy to break the binding forces (surface forces) of the particles. Figure 5 illustrates these principles.

Feed Material Size, Hardness and Density

|

| Figure 5 Click to enlarge |

Size

The size of the largest feed particles will particularly determine the size of the grinding media used. There is a ‘Stress Energy’, SE, required to break feed particles; in general a larger SE is required to break larger particles and therefore larger milling media will be necessary. The media will normally be in the region of 20-40 times larger than the feed particles. Practically, the feed particles need to fit easily between the voids of the milling media.

|

| Table 1 Click to enlarge |

Hardness

The hardness of the feed particles will also impact on the required energy levels. If the particles are hard and difficult to break, then more energy will be required to break them down. This may require larger and/or denser milling media or may result in higher mill energy requirements and/or longer process times. Some typical mineral hardness figures and densities are shown in Table 1.

The hardness of the feed particles will also have an effect on the wear rates of the milling media and the machine parts. Generally harder feed materials will result in higher mill and bead wear (see Figure 6 for bead wear). For milling media, the comparative hardness of the feed to the media is a critical factor. The media ideally should have a surface hardness higher than that of the feed. If the reverse situation occurs, there can be excessive wear on the media resulting in rapid loss of milling efficiency. It is also important to consider that the selection of mill lining materials, their hardness and elasticity etc., will significantly affect the rate of overall wear.

|

| Table 2 Click to enlarge |

Density

Feed material density will also have an effect, although this is often overshadowed by considerations of concentration and viscosity of the feed. Nonetheless, it is preferable to use milling media of higher density than all of the target product particles present in the formulation. It is important to consider that many products contain a large number of raw materials; various fillers and pigment types for example. All these materials have different characteristics, yet they all need processing at the same time, through the same milling operation. A paint formulation can contain five to 10 different solid components as shown, for example, in Table 2.

Conclusion

The requirements of the milling process, (comminution/deagglomeration) and the nature of the feed material, are important factors when selecting milling media. The first consideration should be process demand, to ensure that the bead is capable of transferring sufficient energy to achieve the grind action required. This, however, needs to be considered against the overall cost effectiveness of the process. The bead properties, size, etc., need to be matched to process; if this is not achieved, costs can escalate, particularly in terms of energy consumption and machine/bead wear.

For further information e-mail paul.hassall@saint-gobain.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!