Milling Media Review - Part 2: Bead Density Effect

This is Part 2 of an informational review of milling media. The intention is to provide a periodic update of various aspects and considerations when using ceramic media in micro-milling and dispersing applications.

Part 1 of this series (see the April 2008 issue of PCI) detailed the main considerations of bead density effects on mill operation and efficiency. Equally important is the correct choice of bead size to suit particular formulations, applications and process. The following discussion reviews some of the major effects of bead size.

A continued requirement for ever-finer product (nanometer range) and advances in mill technology have led to the development of even finer bead size ranges (0.1 - 0.5 mm) (Figure 1).

SE ∞ p . V2 . d3, where

p = bead density

V = rotation speed

d = bead diameter

Beads must have sufficient energy to break the target particles and must be large enough to effect comminution.

The minimum bead size relates to the size and hardness of the target particles. The bead must be 20 to 40 times larger than the feed material to effect grinding. Typically this ratio falls within the range of 20-40:1 (Figure 2).

Example: Feed material at 50 microns

0.05 mm x 20 = 1.0 mm bead

0.05 mm x 40 = 2.0 mm bead

In practice for general paint production, with similar feed sizes, beads within the range 1.6 – 2.0 mm would be used.

Note: the ratio is affected by the hardness and physical character of the feed material.<

The negative forces due to drag, product flow, viscosity etc., disrupt the milling action. For effective grinding, the positive forces need to be larger than the negative forces (Figures 3 and 4).

The negative forces due to drag, product flow, viscosity etc., disrupt the milling action. For effective grinding, the positive forces need to be larger than the negative forces (Figures 3 and 4).

Beads need to be a certain size (Figure 5). If the bead is too small there is little or no grinding effect. If the bead is too large, there is a limited action, but process time is increased and target grind may not be fully achieved. It may additionally lead to excessive wear problems. The use of an optimum, in this case 1.2 mm bead, results in rapid achievement of target grind.

Beads need to be a certain size (Figure 5). If the bead is too small there is little or no grinding effect. If the bead is too large, there is a limited action, but process time is increased and target grind may not be fully achieved. It may additionally lead to excessive wear problems. The use of an optimum, in this case 1.2 mm bead, results in rapid achievement of target grind.

Stress Number (SN) = NC . PS Np

NC = Number of bead contacts

NP = Number of feed particles

PS = Probability that a particle is sufficiently stressed at contact

For true comminution, grinding of particles: SN ∞ 1/ DGM2

For de-agglomeration of particles: SN ∞ 1/ DGM

DGM = Bead Diameter

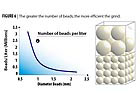

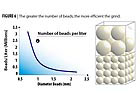

In terms of the beads it is clear that, within limits, the greater the number of beads, the greater the contacts and more efficient the grind. The use of smaller beads is therefore recommended because for a given volume many more beads are present (Figure 6).

Smaller beads are more effective. For a particular set of conditions, say a typical paint base at 5000 cps, it can be seen that smaller beads are the more efficient choice. There is, however, a limit, as bead size becomes too small to overcome negative forces (Figure 7).

Smaller beads are more effective. For a particular set of conditions, say a typical paint base at 5000 cps, it can be seen that smaller beads are the more efficient choice. There is, however, a limit, as bead size becomes too small to overcome negative forces (Figure 7).

A chart of typical bead sizes (Zircon Silica Bead) and target sizes is shown in Table 1.

As a general indication, the maximum achievable fineness (d50) is approximately 1/1000 of the grinding media size. In practice, there are many factors which influence this result. From the above data the ratio would practically be in the range 200-500 times smaller than the bead size used.

Optimum bead size selection is often based on conditions with new bead. All media products wear, and the bead size distribution will therefore change with time. This can have a dramatic effect on efficiency and safety of operation.

For more information, e-mail paul.hassall@saint-gobain.com.

Part 1 of this series (see the April 2008 issue of PCI) detailed the main considerations of bead density effects on mill operation and efficiency. Equally important is the correct choice of bead size to suit particular formulations, applications and process. The following discussion reviews some of the major effects of bead size.

Bead Sizes

Media for micro-milling and dispersion mills are normally available within a relatively limited range of sizes, typically between 3 mm and 0.5 mm. The main constraints have been the mechanical considerations of the milling equipment. This has been true for limitations on the largest sizes usable and the smallest sizes that can be retained within the mill.A continued requirement for ever-finer product (nanometer range) and advances in mill technology have led to the development of even finer bead size ranges (0.1 - 0.5 mm) (Figure 1).

Milling Actions

Grinding, or de-agglomeration, is affected by impact, pressure and shear forces between the grinding media and the mill parts. In each situation there is a critical energy required to break target particles. This ‘Stress Energy’ (SE) is directly proportional to the bead size:SE ∞ p . V2 . d3, where

p = bead density

V = rotation speed

d = bead diameter

Beads must have sufficient energy to break the target particles and must be large enough to effect comminution.

The minimum bead size relates to the size and hardness of the target particles. The bead must be 20 to 40 times larger than the feed material to effect grinding. Typically this ratio falls within the range of 20-40:1 (Figure 2).

Example: Feed material at 50 microns

0.05 mm x 20 = 1.0 mm bead

0.05 mm x 40 = 2.0 mm bead

In practice for general paint production, with similar feed sizes, beads within the range 1.6 – 2.0 mm would be used.

Note: the ratio is affected by the hardness and physical character of the feed material.<

Relative Forces

There are positive and negative forces acting on the bead during the milling process. The positive, due to acceleration and bead mass, contributes to the milling action.

Bead Numbers

For effective grinding, a critical stress energy must be achieved. Equally significant are the number of impacts that occur and the proportion of these that achieve the required stress energy. This is known as the Stress Number (SN).Stress Number (SN) = NC . PS Np

NC = Number of bead contacts

NP = Number of feed particles

PS = Probability that a particle is sufficiently stressed at contact

For true comminution, grinding of particles: SN ∞ 1/ DGM2

For de-agglomeration of particles: SN ∞ 1/ DGM

DGM = Bead Diameter

In terms of the beads it is clear that, within limits, the greater the number of beads, the greater the contacts and more efficient the grind. The use of smaller beads is therefore recommended because for a given volume many more beads are present (Figure 6).

Target Particle Size

The minimum bead size required is determined by the size and characteristics of the feed particles. The final target size, however, must also be considered; we saw in the first graph, that bead size can limit the degree of final grind achieved. The optimum size selection must accommodate both considerations, feed material and desired particle size.A chart of typical bead sizes (Zircon Silica Bead) and target sizes is shown in Table 1.

As a general indication, the maximum achievable fineness (d50) is approximately 1/1000 of the grinding media size. In practice, there are many factors which influence this result. From the above data the ratio would practically be in the range 200-500 times smaller than the bead size used.

Conclusion: Bead Size Selection

For efficient milling, there is an optimum bead size to suit particular process conditions. The bead needs to relate to the feed material, formulation and desired particle size. ZirPro has a range of bead materials available in sizes from 0.1 mm to 3 mm. We have a bead to suit your application (Table 2)Optimum bead size selection is often based on conditions with new bead. All media products wear, and the bead size distribution will therefore change with time. This can have a dramatic effect on efficiency and safety of operation.

For more information, e-mail paul.hassall@saint-gobain.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!