Next-Generation Industrial Waterborne No-VOC Colorants

The results presented in this article show that the use of the next-generation Chroma-Chem® 897 waterborne no-VOC colorants can help paint formulators comply with current and developing VOC coating requirements.

With the amendment of the Clean Air Act in the early 1970s, it was recognized that VOC emissions from paint may accelerate the process by which sunlight and nitrogen oxides generate ozone, which is the major component of smog. Therefore, efforts to regulate VOC emissions in the United States were initiated. The regulations vary depending on the region or state in the United States; however, the most stringent limits were developed in California for architectural and industrial maintenance coatings (AIM).

In the colorants industry, many of the solvents used are considered to be Hazardous Air Pollutants (HAPS), and therefore their use in formulas should be limited. As a result, Colortrend USA LLC commenced the development of Chroma-Chem® 897, the next generation of no-VOC colorants, consisting of 15 volumetrically and gravimetrically dispensable colorants, for both depot and in-plant tinting systems.

Chroma-Chem® 897 colorants combine minimal VOC levels with superior performance and coloristic properties. These colorants are designed to have a broad range of compatibility with commercially available high-performance waterborne industrial coatings, i.e. aliphatic acrylic polyurethane, modified acrylic terpolymer, epoxy-acrylic, epoxy-amine adduct, acrylic enamel, acrylic urethane, acrylic-modified alkyd, and PUR alkyd. Chroma-Chem® 897 colorants are free of Alkyl Phenol Ethoxylate (APE) and aromatic compounds, therefore helping paint manufacturers reach the proposed VOC content limits without sacrificing the final coating performance. Except for Burnt Umber, which uses a naturally occurring pigment that contains Manganese, all of the colorants are HAPs free.

Colorant Evaluations

Colorants were evaluated considering two areas, as shown in Figure 1:

|

| Figure 1 Click to enlarge |

- Quantifiable on colorant – The inherent properties of the colorant such as aging stability, freeze-thaw stability, dispensability, VOC, etc.

- Quantifiable on paint – The impact of colorants on different paint properties. The colorants were evaluated at 10% by volume for stability in paint, sag resistance, drying, curing (Persoz Hardness), accelerated weathering (both QUV-A and Xenon Arc), condensation test, salt spray, compatibility, leveling, sag resistance, gloss, salt spray, etc.

Quantifiable on Colorant

Aging

Chroma-Chem® 897 colorants were placed in the oven at 50 ºC, and the viscosity change was monitored over four weeks. After four weeks aging, the strength difference between the aged colorants and the samples kept at room temperature were evaluated. Results showed no significant difference between the samples.

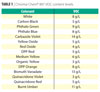

|

| Table 1 Click to enlarge |

Freeze/Thaw Stability

When waterborne colorants are shipped during cold weather, they may experience cycles of freezing and thawing. Freeze/thaw cycles may cause more damage than when the colorants are subjected to steady freezing. The effect of freeze/thaw cycling on the viscosity, grind and color strength of Chroma-Chem® 897 colorants was evaluated at -18 °C for 17 h, followed by 7 h undisturbed at room temperature. This procedure was repeated for five cycles. The strength differences between one, three and five cycles were compared with the colorants kept at room temperature. Results showed no significant differences between the samples. The color differences of both the aged and freeze-thawed samples were evaluated in a pastel acrylic-urethane one-component base using a colorant level of 10% by volume.

VOC Evaluation

|

| Table 2 Click to enlarge |

Chroma-Chem® 897 was developed to have VOC lower than 50 g/L by ISO 11890-2 as shown in Table 1. ISO 11890-2 or ASTM D 6886-03 are the preferred methods when the VOC content is expected to be between 0.15% and 15% by mass. There are multiple GC test methods based upon boiling point markers, columns, temperature and time profiles. One of the main differences between ISO and ASTM is that ISO has a boiling point cutoff at 250 °C using n-tetra decane as a marker, while the ASTM method has no cutoff. Therefore, ISO considers anything below the BP as a VOC, while ASTM considers all non-exempt compounds as VOC. ASTM D 6886-03 has a reported detection limit of 0.05% (500 ppm) though a revision (D 6886-rev) is going to ballot, which will lower the detection limit to 0.005% (50 ppm). ISO 11890-2 does not have a detection limit.

Quantifiable on Paint

The colorants were evaluated in nine commercially available industrial waterborne paint base chemistries; 2K aliphatic acrylic polyurethane, modified acrylic terpolymer, 2K epoxy-acrylic, 2K epoxy-amine adduct, acrylic enamel, 2K acrylic urethane, 1K acrylic-modified alkyd, and PUR alkyd. To see the impact of these colorants on paint properties, examples are shown below with the addition of either Yellow Oxide (an inorganic colorant) or DDP Red (an organic colorant) to a 2K aliphatic acrylic polyurethane.

|

| Table 3 Click to enlarge |

Stability in the Paint

An aliquot of 10% by volume of each colorant was added to the paint base and placed in the oven for three weeks at 40 °C. Changes in viscosity, pH and sag resistance were evaluated against the initial sample. Results in Table 2 show that no significant change occurred in the paint’s physical properties compared to the untinted paint. Therefore, no modification of the paint base is needed when tinted with Chroma-Chem® 897 colorants.

|

| Figure 2 Click to enlarge |

Drying Time

The drying time was measured according to ASTM D 5895 using a dry time recorder from BYK Gardner, model number BK.3. An aliquot of 10% by volume of each colorant was used and evaluated for drying time differences between the base itself and the tinted base. Results in Table 3 show no differences in dry time with the addition of either the inorganic or organic colorants, demonstrating that the addition of Chroma-Chem® 897 colorants would not have a negative impact on the drying properties of the paint.

Impact on Gloss During UV Exposure

The addition of colorants can influence the UV resistance of some coating systems due to chemical incompatibility between the colorant and the binder of the coating. The evaluation of gloss during the time of exposure to UV radiation can provide us with an indication of whether the paint resistance was affected. In order to evaluate the impact of Chroma-Chem® 897 colorants on retention of the film gloss, 10% by volume of colorant was added to the paint base, cured for 7 days, and exposed to QUV-A and Xenon Arc for 3500 h. Results have showed that Chroma-Chem® 897 colorants will have minimal impact on the gloss of the paint film when exposed to UV radiation.

Impact on Water Resistance

|

| Figure 3 Click to enlarge |

Colorant addition may have a negative influence on the water resistance of some coating systems due to chemical incompatibility between the colorant and the coating binder. The evaluation of adhesion and film integrity of the paint after being exposed to 100% humidity at 40 °C in a QCT condensation tester can provide us with an indication of whether the paint resistance was affected. In order to evaluate the impact of the next-generation colorants on the film integrity under high humidity conditions, 10% by volume of colorant was added the paint base, cured for 7 days and exposed in the QCT for 1680 h. As shown in Figure 2, the coatings tinted with Chroma-Chem® 897 showed no blisters or loss of adhesion, indicating that the colorants will have minimal impact on the coating’s water resistance.

Impact on the Anti-Corrosive Property of the Coating

The addition of colorants can affect the anti-corrosive property of some coating systems, due to chemical incompatibility between the colorant and the binder of the coating. The evaluation of film degradation after being exposed to 1680 h of salt spray at 35 °C can provide us with an indication of whether the paint resistance was affected. In order to evaluate this property, 10% by volume of colorant was added to the paint base, cured for 7 days and exposed in the QCT for 1680 h. Results have showed that Chroma-Chem® 897 colorants have no impact on the coating’s anti-corrosive property (Figure 3).

|

| Table 4 Click to enlarge |

Impact on Gloss, Hardness and Blocking Resistance

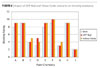

The impact of Chroma-Chem® 897 colorants on gloss, hardness and face-to-face blocking resistance was determined in the paint base chemistries listed in Table 4.

For gloss determination, 10% colorant was added, the coating cured for 7 days on metal substrate, and tested for gloss at 60° angle. As shown in Figure 4, excellent gloss retention was obtained.

|

| Figure 4 Click to enlarge |

The ability for a coating to not stick to itself upon contact when pressure is applied is an important requirement for industrial applications. In order to evaluate how the next-generation colorants would affect the blocking resistance of the paint, the ASTM D 4946-89 method was used. Colorant (10%) was added to the bases and applied to the substrate with a 6 mil bird applicator. The specimen was dried for 7 days and placed face to face in the oven at 50 °C, with a pressure of 1.8 psi over the specimen. After 30 minutes, the specimens were removed from the oven, cooled for 30 minutes at room temperature and peeled apart. Chroma-Chem® 897 colorants did not reduce and in some cases improved the blocking resistance of paint bases, as shown in Figure 6.

|

| Figure 5 Click to enlarge |

Impact on Sag Resistance

When a coating is applied on a non-horizontal substrate, it may sag due to gravity. Sag resistance is interrelated to the composition, viscosity and thickness of the coating. It is desirable that the paint base preserve its anti-sag property after the addition of colorants. Sag resistance was evaluated according to ASTM D 4400. Results, as shown in Figure 8 for Phthalo Green Colorant, confirm that the addition of 10% by volume of the colorant improved the sag resistance of the paint when compared with competitor colorant.

|

| Figure 6 Click to enlarge |

Dispensability

Dispensability of no-VOC waterborne colorants has been a concern in the market due to the colorant tendency to dry in the nozzles. The correct balance of colorant formulation can provide good dispensability of the colorants without compromising other physical properties. Chroma-Chem® 897 colorants were tested in automatic dispensing, closed-nozzle manual dispensing and opened-nozzle manual dispensing machines. Results obtained showed that colorants had satisfactory performance with both automatic and closed-nozzle manual dispensing machines, and can endure a minimum of three

|

| Figure 7 Click to enlarge |

weeks in the opened-nozzle dispensing machine without cleaning the nozzle.

Conclusion

|

| Figure 8 Click to enlarge |

The results presented in this article show that the use of the next-generation Chroma-Chem® 897 waterborne no-VOC colorants can help paint formulators comply with current and developing VOC coating requirements. The colorants are not sensitive to pH variation, will provide a broad range of compatibility, have minimal effect on the performance in different paint base chemistries, and in some cases improve the paint physical properties, as summarized in Table 5. This is a new step for no/low-VOC waterborne colorant technology, with Chroma-Chem® 897 becoming the benchmark for no-VOC waterborne industrial colorant technology.

|

| Table 5 Click to enlarge |

The author would like to acknowledge Mier Gu, John Gorman and David Rivera from Colortrend USA LLC, and Mark Westera from Colortrend B.V. for their contributions and data.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!