Next-Generation Architectural Colorants

aga7ta, iStock / Getty Images Plus, via Getty Images

In efforts to meet increasingly stringent regulatory requirements and growing consumer expectations, architectural coatings companies must consider the sustainability impacts of their products. Near-zero-VOC architectural bases and low-VOC colorants continue to gain traction in North America as paint companies and colorant suppliers have advanced their knowledge and tools for successful low-VOC formulations. Additive companies have recently joined this trend with the advancements in surfactant and dispersant technology for low-VOC applications.

Specialty chemicals and minerals supplier, Vibrantz Technologies, developed the next generation of architectural colorants offering the lowest VOCs and highest pigment-loading capabilities in the industry. These colorants deliver superior performance, an extended shelf life and global compliance. The study below includes a series of tests comparing Vibrantz’s novel colorants to industry-standard colorants, utilizing several types of architectural bases. Tests performed include viscosity drop, blocking resistance, open time, and base compatibility.

Innovation During Crises

Advanced colorants were developed during a global crisis most companies experienced. The restrictions developed post-pandemic, coupled with raw material shortages, made technical work challenging to complete. Vibrantz’s global technical color solutions team was tasked with creating a new architectural line for liquid colorant dispersions that demonstrated significant sustainability advancements. The most important characteristics of this new product line were identified as:

- Biocide free

- Raw material sustainability

- Superior colorant stability

- Zero impact on paint properties

- Higher pigment solids

- Extremely low VOC

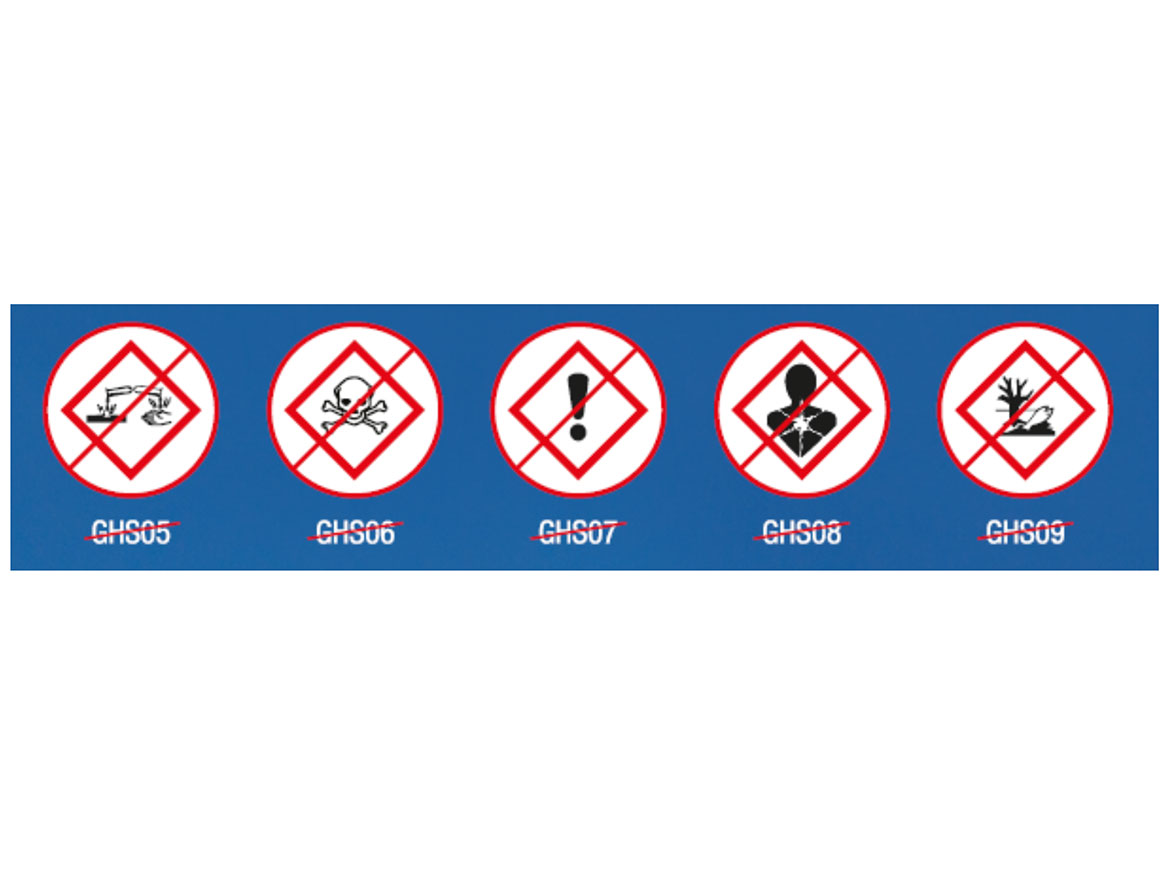

Vibrantz’s advanced colorants are market differentiators with their combined properties. They are GHS icon free, meaning that they are non-corrosive, not acutely toxic, and not hazardous to the environment or health.

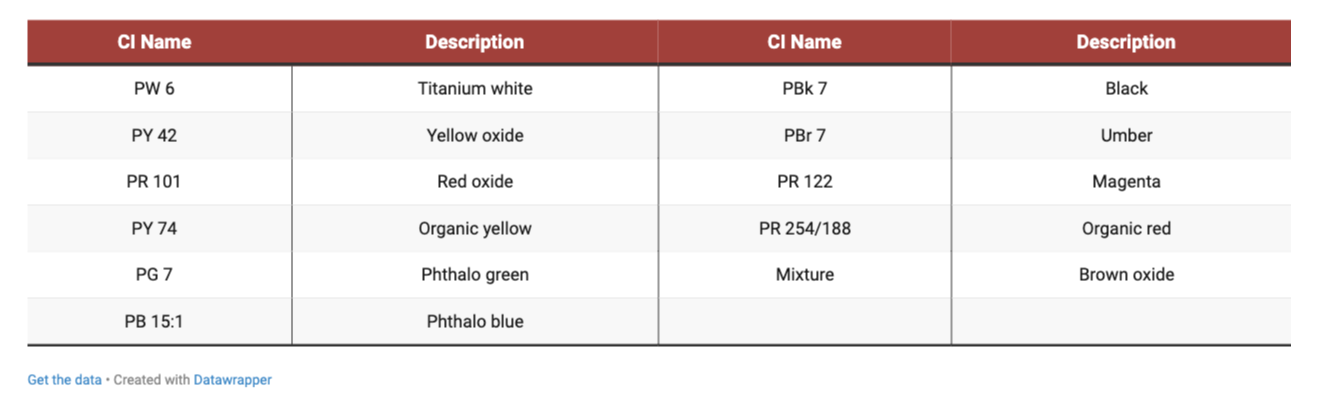

These colorants have the lowest VOC content possible, high pigment solids content, and are formulated for both point of sale (POS) and in-plant tinting. They provide unsurpassed canister stability, rheological stability, and no tip dry. The colorants offer superior performance in paint base interaction; minimal viscosity drop, blocking and scrub resistance; no surfactant leaching; and improved open time (Table 1).

Results

As part of the process for creating the novel colorants, exhaustive testing occurred with internal- and external-benchmark, low-VOC, waterborne colorants in various global paint bases. Several industry-standard testing methods were incorporated with the idea of matching paint company testing.

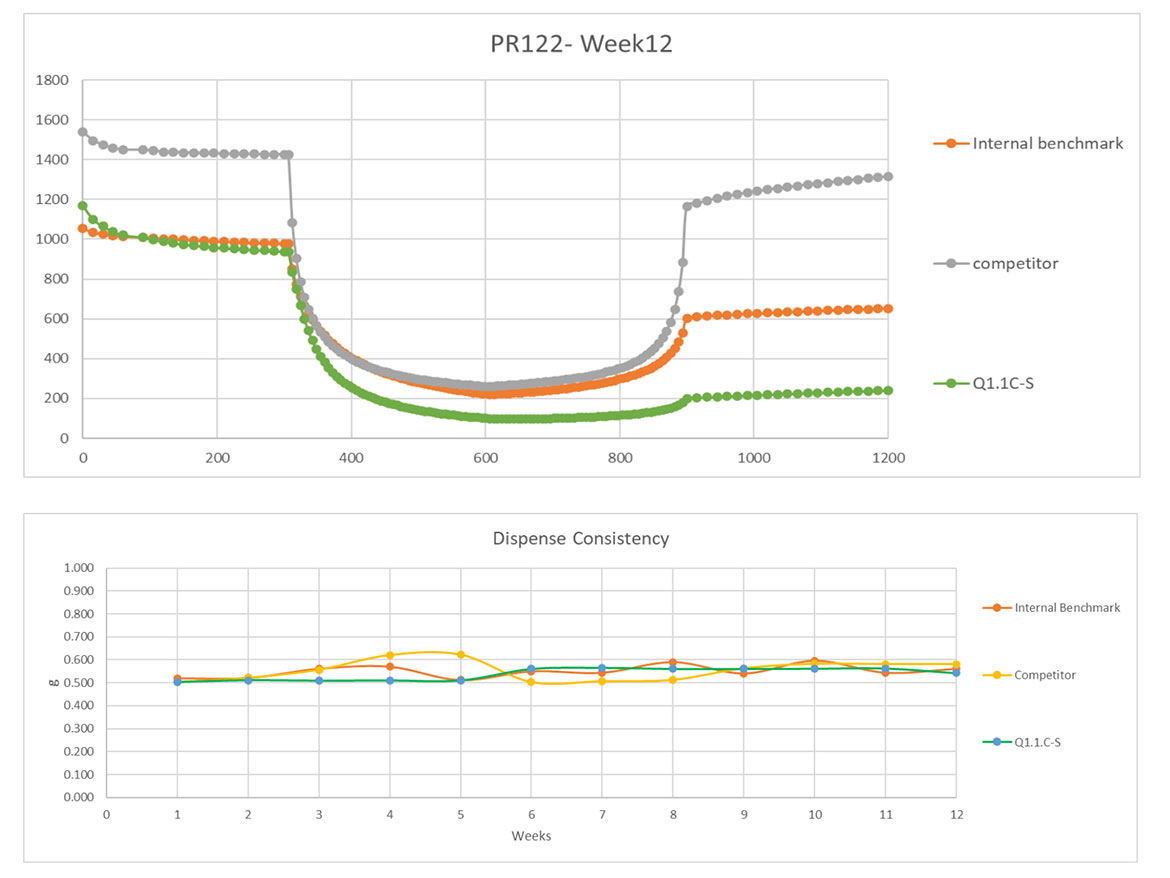

Testing for biocide contamination involved sterility challenges of GHS icon-free colorants compared to the benchmarks. The Vibrantz team observed colorant sterility from a three-pronged approach: incoming raw materials, plant hygiene, and process controls. The colorants passed the 12-week dispenser stability testing, allowing them to be GHS icon free (Figure 1).

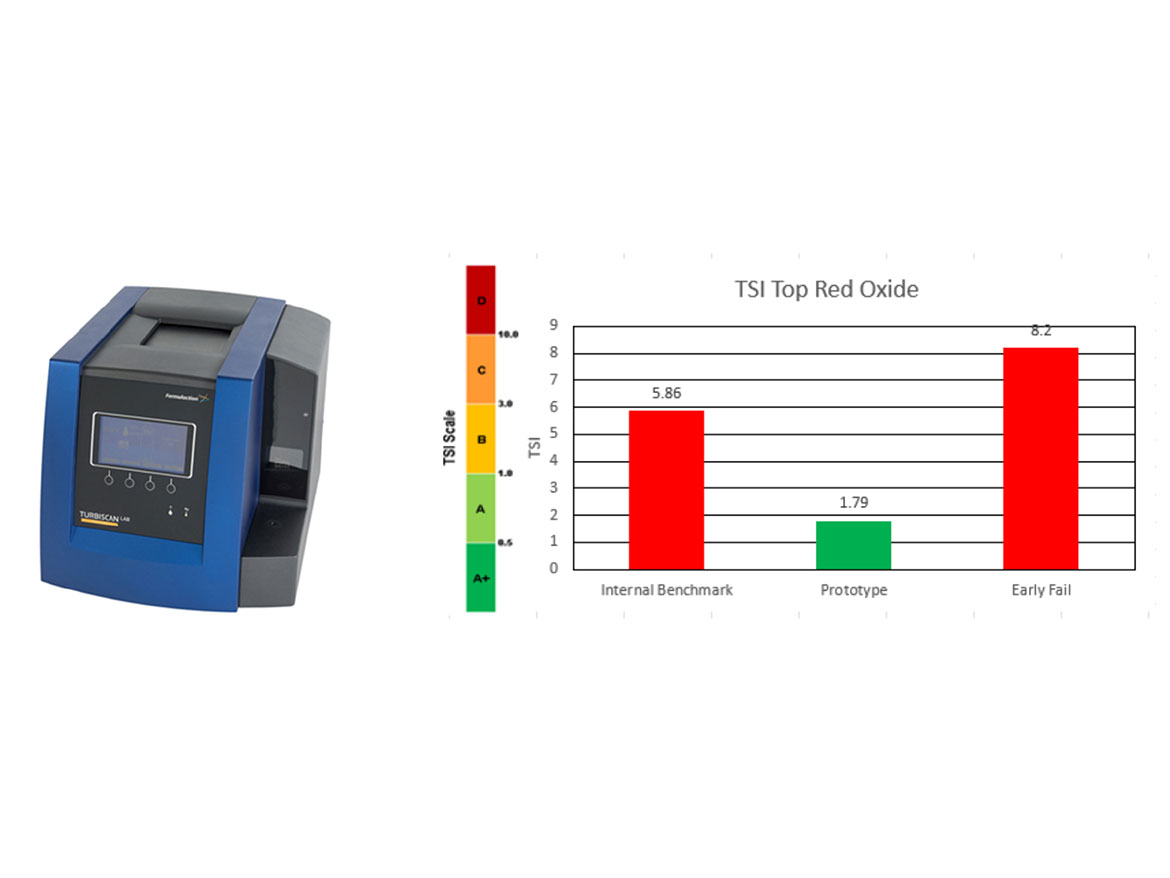

To test the settling of the colorants, the team utilized Formulaction’s Turbiscan – a lab instrument for comparative and benchmark analyses (Figure 2). Laser reflection and transmittance determine the “activity” of the colorant over a period of time. It is best used as a “fast fail” test for formulations. The cycle of stability is changed from months to days. The Turbiscan Stability Index (TSI) value from the Turbiscan provides a quick comparative visual.

When evaluating canister stability and tip dry, normal 12-week dispenser testing occurred alongside rheology testing of the colorants (Figure 3). There was no tip drying or fluctuations in dispensing observed, even with a magenta at a higher pigment loading.

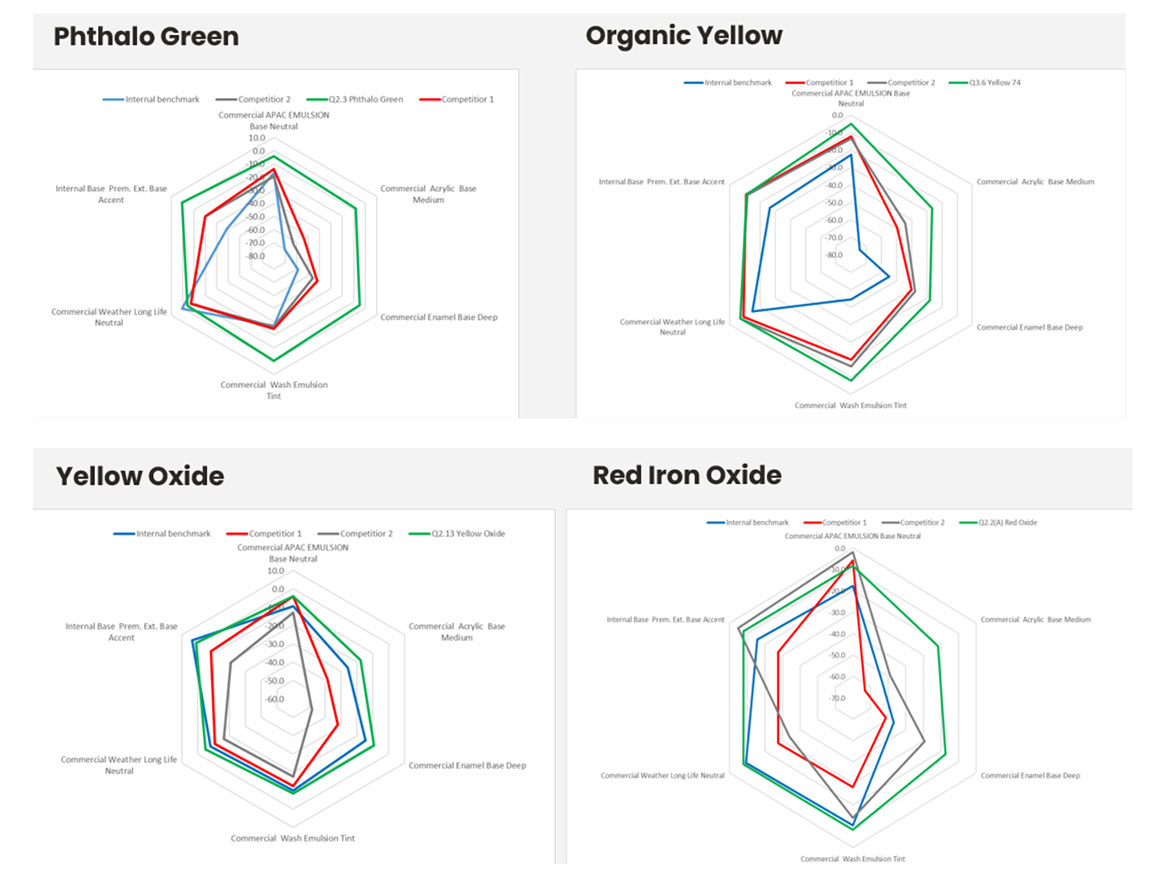

Viscosity drop comparisons were performed on six various types of global architectural bases to ensure superior properties from the colorants in comparison. Internal benchmarks and competitive colorants were incorporated at 12 ounces per gallon. Yellow oxide comparison is shown below as an example (Figure 4).

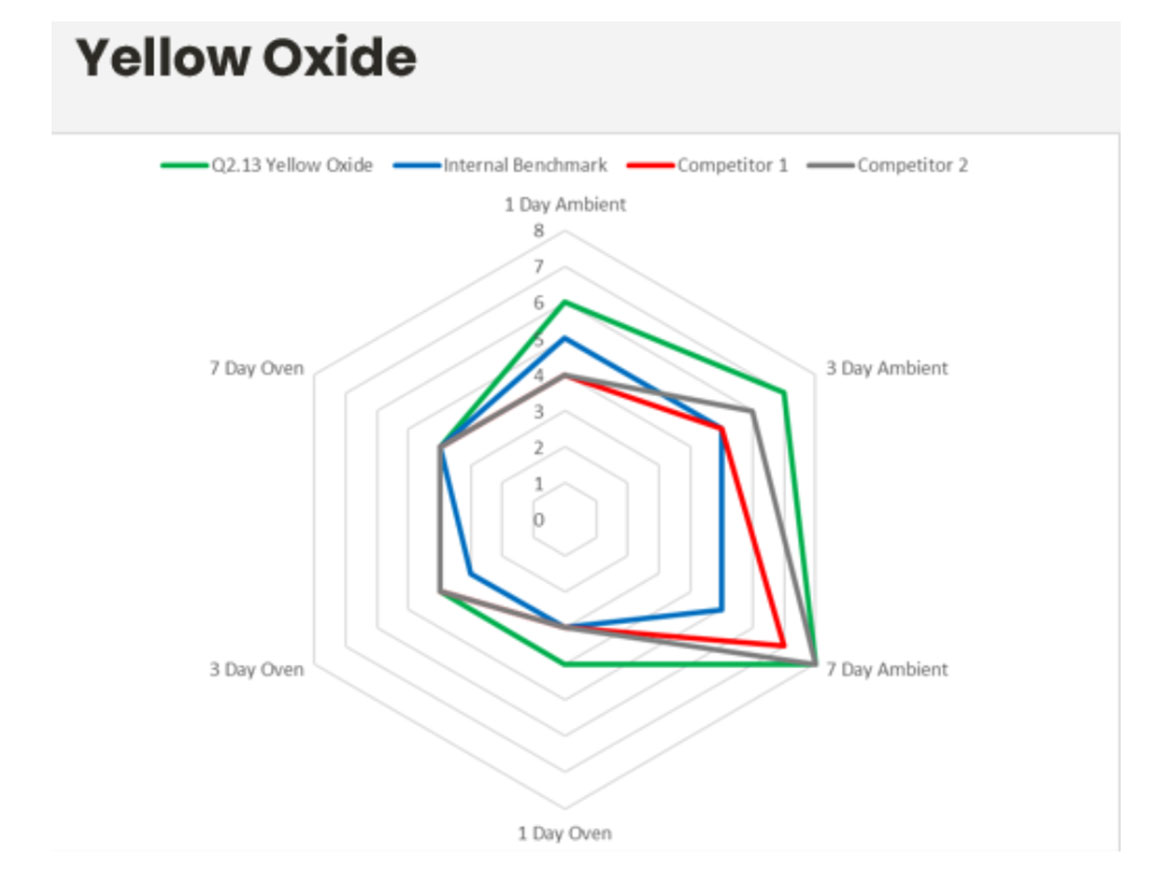

Results of blocking resistance testing (ASTM D4946) on an internal base show a marked improvement for low-VOC, resin-free waterborne colorants. For example, the yellow oxide spider graph in Figure 5 shows one-, three-, and seven-day improvements.

Colorimetric comparisons show a drastic increase in tinting strength for the benchmark POS colorants, as seen in the drawdowns displayed in Figure 6. The pigment load has been increased for each colorant. The organic yellow has an increase in opacity but remains transparent at a higher pigment loading.

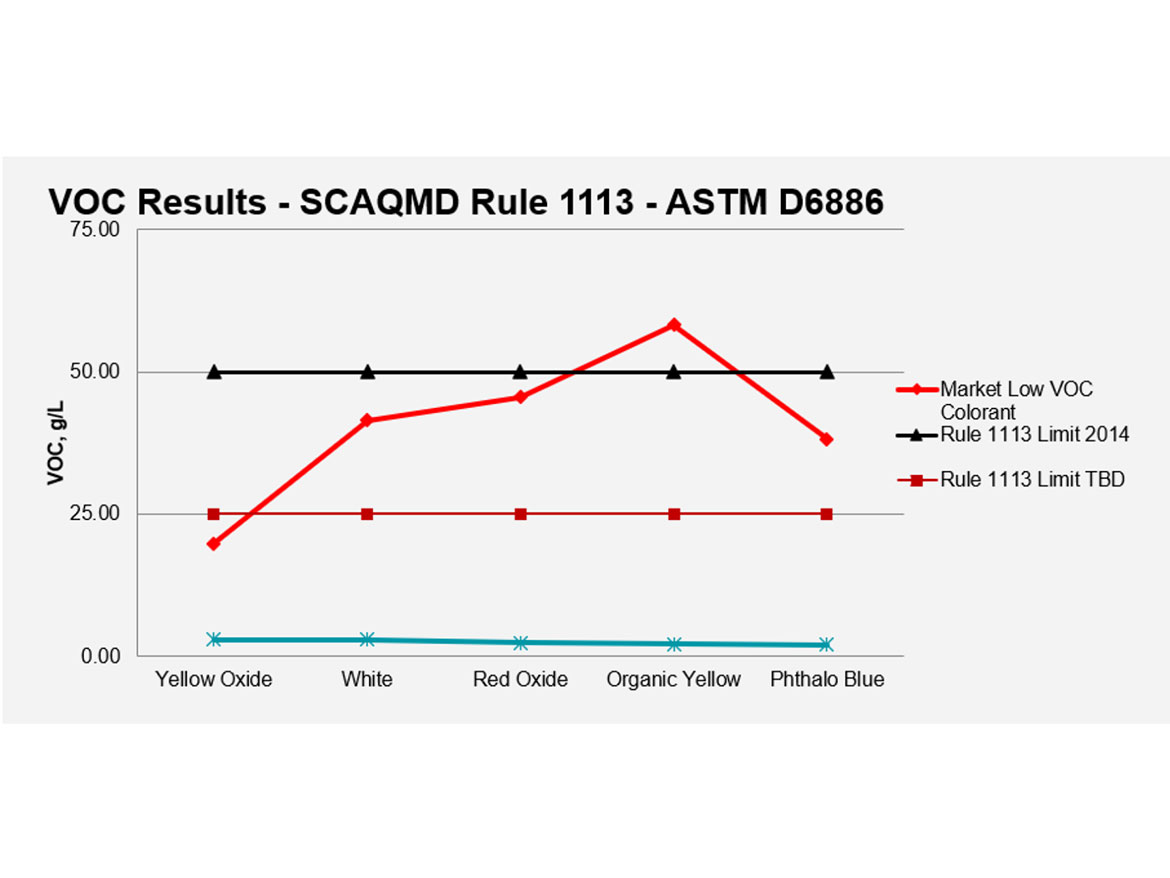

VOC testing shown in Figure 7 also reveals that they are the lowest on the market comparatively.

Advantages

Vibrantz worked with global industry partners to find the right combination of formulary ingredients that are available worldwide.

The higher pigment loading allows for increased opacity and higher color saturation in color formulas. It also allows for use in both POS, depot, and in-plant tinting.

GHS icon free is critical during these times of industry-wide environmental and health concerns. Due to the continued persistence by regulatory and other market influencers to lower biocide levels, Vibrantz formulated for the future to develop biocide-free colorants.

Disadvantages

A disadvantage to being a new benchmark is that it does not match colorants from any other lines. Color database work would need to be done to replace formulations. The Vibrantz Color Science department can help customers as they are characterizing the novel colorants into common databases.

What’s Next

Sampling of these colorants is necessary along with continuing extensions to the line with new pigments not previously formulated. After sampling is completed, the team will collect and analyze markets responses.

If you're interested in sampling NXT colorants or learning more about the new product line, contact ProductManagementGroup@vibrantz.com.

Acknowledgments

Special thanks are in order for this global team effort headed by Dr. Brij Mohal and executed by Smita Shelar. Contributors for testing, concept, requirements, and multiple discussions were supplied by Peter Thommassen, Nima Jafari, Luc Driessen, and Scott Becker.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!