The Next Generation of Condensation and Corrosion Protection

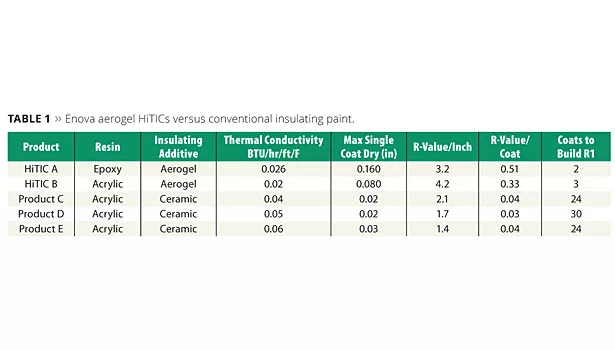

Widely known as the world’s best insulating solid material, silica aerogel-enabled coatings are redefining the world of paint with thermal benefits. Recognizing the advantages of a high-performance insulative coating has driven some coatings manufacturers to explore the use of silica aerogel as a paint additive to achieve significantly lower thermal conductivities. This new class of high-performance coatings, called Highly Thermally Insulative Coatings (HiTICs), is now finding opportunities in condensation and corrosion prevention.

Condensation, and the corrosion it causes, is a major issue in many industrial and architectural structures. Condensation occurs when the temperature of a surface drops below the dew point of the surrounding air, causing moisture in the air to condense on that surface. When this takes place, condensate pooling can cause safety concerns. Affected equipment is likely to experience conditions that can cause corrosion, and the possibility of biological growth (mold), resulting in health and asset protection issues.

Traditional insulation can be used to try to reduce the risk of condensation by increasing the surface temperature above the dew point of the surrounding air, but this method is often met with limited success. Since many insulation systems are porous, condensation still occurs on the surface of the substrate or within the insulation layer, resulting in a higher risk of corrosion under insulation (CUI). In addition to the risk of corrosion, the presence of condensed water in the insulation material dramatically limits its thermal effectiveness, thereby increasing energy consumption. Alternatively, surface heaters can be used to warm the substrate above the dew point, but these tend to be energy intensive and are not always practical.

Aerogel-enabled insulative coatings present engineers and designers with a new solution to this old problem. These HiTICs are advantageous because of their extremely low thermal conductivity (a measure of a material’s ability to transfer heat), as well as their high film build (the thickness that can be applied in each coat). These combined material properties allow for superior insulation performance with minimal coats, resulting in lower installation cost. Table 1 demonstrates this performance advantage for aerogel-enabled coatings as compared to conventional insulating paints.

Condensation Testing

To demonstrate the performance gain realized with aerogel-based coatings, two different lab configurations were constructed and tested. The first configuration, shown in Figure 1, consists of an aluminum channel section with a single side of an aluminum window frame system welded onto it. Coolant was run through the channel section to create a temperature profile within the frame that would be representative of a cold winter day (approximately 20 °F). Four coating conditions were then represented on different sections of the aluminum frame:

- No coating;

- 40 mils (1 mm) coating;

- 120 mils (3 mm) coating;

- 160 mils (4 mm) coating.

Temperature sensors were attached to each of these regions, and temperatures were monitored over time. As seen in Figure 1, the uncoated areas experienced a significant amount of condensation. However, on the areas where the coating was present, condensation did not occur. The surface temperature measurements are shown in Table 2.

The measurements showed a 10.1 °F difference between the temperature of the uncoated surface and the 160 mil coated surface. What this means is the use of the coating has shifted upwards by 10.1 °F – the ambient dew point at which condensation will occur on that surface. For standard room conditions (68 °F), this would mean a shift in relative humidity from 47% to 69% before the onset of condensation on the surface.

To further demonstrate this phenomenon, a full window frame section was constructed in a similar manner to that described earlier. This system, shown in Figure 2, had an aerogel-based coating (80 mils or 2 mm) on the left half of the aluminum frame and no coating on the right half. A close-up shot of the window, in Figure 3, clearly shows condensation on the uncoated surface and none on the textured, aerogel-coated surface.

Since the benefit HiTICs provide is based on raising the surface temperature of the substrate, the same impact seen in the architectural example is also transferable to the industrial area. For large storage tanks or process piping, the same principle holds true, making aerogel-based coatings an excellent solution for applications where condensation formation and the resulting CUI are a concern.

The Future of Insulative Coatings

With this new generation of HiTICs utilizing aerogel with thermal conductivities comparable to bulk commodity insulation, industries can now consider insulating surfaces that have been difficult to insulate due to topography, humidity, chemical exposure, and maintenance or space requirements to minimize or even eliminate condensation and, thereby, enhance corrosion protection. By combining corrosion protection and thermal resistance into a single product, the issue of trapped moisture within traditional insulation forms is effectively eliminated. n

For more information, visit www.cabotcorp.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!