A New Era in Superwetters for Waterborne and UV-Curable Coatings and Inks

The growth today in waterborne and radiation-cured coatings and inks far exceeds that of its solventborne equivalents. The need for lower VOCs, “greener” materials, improved food safety and reduced economics (inventory reduction and faster production speeds) all contribute to this growth, and this in turn increases the need for superwetters. Why? As formulators transition from solventborne coatings and inks to create healthier, safer and more eco-friendly systems, performance requirements bring to light issues and disadvantages associated with waterborne and radiation-curable systems. In particular, many of the surfactant packages utilized have the negative effect of stabilizing foam from air incorporation during coatings production and application. In addition, in waterborne coatings specifically, the inherent high surface tension of water creates the potential to cause surface defects such as craters and poor wetting on substrates.

Credit: Dow Corning Credit: Dow Corning

|

| Table 1 Click to enlarge |

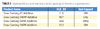

With the growth of waterborne and radiation-curable coatings and inks comes the development of more binder systems, and formulators find they require a wider portfolio of wetting additives to choose from when developing new formulations. No one, universal solution is suitable across a wide range of formulations and substrates because inconsistent performance; lack of regulatory compliance; poor pH stability; poor performance in demanding, high-speed applications; and cost all bring the formulator problems. In the coating and ink industries, silicone materials have been developed and used for many years to improve the surface appearance and properties of many systems, including wetting, but this technology has also suffered from inconsistent performance. Dow Corning has recently launched four 100% silicone polyether co-polymers with good compatibility in waterborne and radiation-curable systems to provide good substrate wetting consistently over a wide range of formulations, pH ranges and substrates.

This article describes an application study comparing the performance of these four unique silicone polyether co-polymer superwetters to commercially available surfactants on the market (acetylenic diols and silicone polyether copolymers, including Gemini surfactants) (Table 1).

Credit: Dow Corning Credit: Dow Corning |

| Table 2 Click to enlarge |

Superwetters

Credit: Dow Corning Credit: Dow Corning |

| Table 3 Click to enlarge |

The superwetters provide excellent static surface reduction (Table 3).

While the ethylene oxide content (HLB) doesn’t influence the surface tension directly in water, this can affect the solubility and therefore performance of the surfactant in a coating or ink formulation. Therefore, having a range of HLB values allows the formulator to choose the right product for a given formulation.

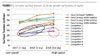

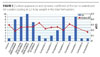

While static surface tension will give a theoretical indication of how much a surfactant can reduce the surface tension of a given solution to achieve good wetting, Dynamic Surface Tension (DST) is more reflective of real-life performance in a coating or ink application process, as this measures how quickly a surfactant migrates to the air/liquid interface to do its work. Figure 1 shows DST results of the superwetters and competitor surfactants at 0.2% by weight in water. DST is measured by using a bubble tensiometer that bubbles air through the test liquid at an increasing rate, during which the maximum pressure that is required to form a bubble is measured. As the bubble rate increases from 1 bubble per second to 10, the time to create the new interface (liquid/air) decreases.

Credit: Dow Corning Credit: Dow Corning |

| Figure 1 Click to enlarge |

All of the superwetters perform well at low to medium application speeds, as indicated by low DST at 1 and 5 Hz. In particular, Dow Corning® 502W Additive and competitor additive 7 maintain their very low DST at high speed. This gives an indication that both products will be useful for wetting in high-speed applications and challenging conditions such as spraying. However, this test is only an indication and does not reflect real-life performance in all cases, and we will see later that while the performance of Dow Corning 502W is supported with consistent application data, this is not the case for the competitor 7 additive.

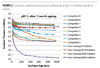

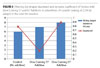

High-pH paints are most common in the decorative market, and here, long-term stability of a wetting additive is key. Figure 2 shows the DST performance of the surfactants at pH 11 after 1 month aging. Long-term performance of Dow Corning 500W Additive at pH 11 was achieved after 1 month aging, providing low surface tension consistently. This allows the formulator to use it in high-pH formulations with confidence of long-term wetting performance at the end-use stage. The data indicates that this additive achieves long-term performance at high pH due to the stability of the non-reactive acetoxy-end capped group.

Credit: Dow Corning Credit: Dow Corning |

| Figure 2 Click to enlarge |

In this part of the application study, each surfactant was compared at 0.2% by weight in each formulation. The following properties were evaluated to compare performance:

1. Surface appearance by visual assessment of surface defects (wetting and leveling);

2. Slip (coefficient of friction).

With the addition of surfactants to a formulation comes the risk of foam stabilization, and the impact on foaming was evaluated by measuring foam height after high-speed shearing.

Performance in Waterborne Polyurethane and Acrylic Wood Parquet Lacquer Formulations

The two typical wood coating formulations shown in Tables 4 and 5 were used to evaluate the performance of the superwetters. The first is based on a polyurethane dispersion, the second on an acrylic dispersion.

Credit: Dow Corning Credit: Dow Corning |

| Table 4 Click to enlarge |

Credit: Dow Corning Credit: Dow Corning |

| Table 5 Click to enlarge |

The old adage, “seeing is believing”, is certainly true in the case of the superwetter performance. Figure 4 shows the wetting performance of the waterborne polyurethane acrylic wood parquet lacquer with and without a superwetter; in this example Dow Corning 67 Additive is shown.

This is demonstrated in Figure 6, where the performance of Dow Corning 67 Additive has been compared to Dow Corning 57 Additive in a solventless UV-curable coating. In this formulation we can see that the 67 Additive gives the superior wetting performance with no impact on slip (coefficient of friction), while the 57 Additive gives a lower wetting performance but with a dramatic decrease in slip. This differentiation in slip performance between the superwetters and other additives gives formulators the choice to customize their formulation to suit the end application.

Credit: Dow Corning Credit: Dow Corning |

| Figure 3 Click to enlarge |

Performance in Waterborne Flexographic Ink

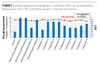

In this example on PET (Figure 7), another low-energy substrate that is very difficult to wet, Dow Corning 500W and 501W Additives excel in performance, an indication that the non-reactive end capping is influencing the performance. The coefficient of friction remains unchanged; this can be particularly important in printing applications where high slip results in difficulties in stacking printed items. Again, if a reduction in the slip properties is required, this can be adjusted using a customized slip additive such as Dow Corning’s 57 or 51 Additive. This differentiation in slip performance between the superwetters and these other additives gives formulators the choice to customize their formulation to suit the end application.

Credit: Dow Corning Credit: Dow Corning |

| Figure 4 Click to enlarge |

Foam Stabilization

While the addition of surfactants achieves wetting on difficult-to-wet substrates, they potentially also have a negative effect on foam behavior of inks and coatings in some cases, leading to foam stabilization during production and application at high shear. This is true for all types of chemistries used.

Credit: Dow Corning Credit: Dow Corning |

| Figure 5 Click to enlarge |

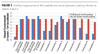

The effect of these surfactants on the foaming property of a waterborne flexographic gravure ink was measured by evaluating foam height after high-speed shearing. In Figure 9 we can see that some foam stabilization is evident with both the superwetters and competitive additives. Where the surfactant does the best job it unfortunately results in the highest amount of foam – but conversely, low foam stabilization cannot compensate for poor wetting!

Credit: Dow Corning Credit: Dow Corning |

| Figure 6 Click to enlarge |

Important to the formulator is that this foam can be controlled. Figure 10 clearly demonstrates that with addition of Dow Corning defoamers at only 0.1% by weight to the total formulation, we see a reduction of foaming.

Conclusion

Credit: Dow Corning Credit: Dow Corning |

| Figure 7 Click to enlarge |

Dow Corning’s superwetters are effective in providing consistent coating performance in a wide range of formulations. In particular, our 500W Additive provides excellent performance with high pH stability, and our 502W Additive is especially suitable for very high-speed printing and challenging spray applications. Coatings formulators can select superwetters based on their different performance needs to get consistent product performance.

Credit: Dow Corning Credit: Dow Corning |

| Figure 8 Click to enlarge |

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!