Powder Coating: New Generation of Spray System Controls

Digital spray-system controls have been on the market for about two years, and they do offer some unique functions that can often produce material savings and quality improvements. This is especially true if you even minimally batch your different products.

The main claim to fame of the digital control systems is their ability to minimize the number of variables in your system, give you more control over the application parameters, and make your system less susceptible to an operator error or the effects of variables outside the system. The high level of control and flexibility of the new systems often results in coating and quality cost savings.

There are three areas in which cost savings can be achieved. First, if you are using a cartridge-based powder-recovery system and reclaim high-volume powders, savings can be realized from controlling your applied coating cost and making sure that not half a mil extra goes on your parts. Second, if your reclaim system utilizes cyclones that are only 95% efficient, additional savings will result from improvements in powder application efficiency. Spray-to-waste operation necessitates that your application system efficiency be maximized. Finally, very tangible savings can result from quality improvements.

Let's look at some extra capabilities offered by the new-generation equipment. Maybe, some of them can benefit your application.

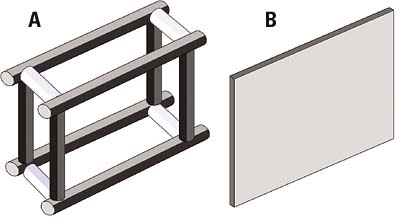

For one, new systems have the ability to store multiple application-system settings in memory. The different settings (commonly called "presets" or "recipes") can be programmed for different product types and quickly retrieved when you are changing from coating one product to another. For example, when using electrostatic coating processes, one commonly observes a "wrap" effect-coating deposition on the side of the product facing away from the spray guns. On some narrow parts, wrap contributes significantly to the applied coating formation. Compare the two parts in Figure 1. Both require 2 mils of coating. Part A is a three-dimensional, tubular product while part B is a solid panel. In a conventional, predigital powder coating operation, the spray system is likely to be set to apply 2 mils on part B. Meanwhile, if part A is sprayed with the same settings, the wrap will contribute an extra mil of coating to each side of the tubular part. Thus, while part B receives the required 2 mils, part A will end up with 3 mils.

With a digital spray system control, part A can have its own coating recipe that will save you that extra mil of applied coating.

Another example: Different powders reach full opacity (complete hiding) at different coating thicknesses. For example, white powder may require 2 mils of applied coating for full opacity; black powder may only need 0.9 mil; yellow, 1.6 mil. Most systems that apply decorative coatings would have their spray systems set to apply 2 mils, with all powders incurring extra applied coating costs when spraying black and yellow powders. With a digital control system, you can have different settings programmed for different powders.

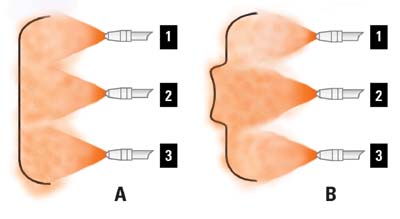

Automatic gun triggering can produce tangible operating cost savings and is often integrated into the new digital control systems. If you have more than three or four seconds worth of line gaps between your parts, turning the guns off during the gaps can not only minimize the overspray but also reduce the picture-framing on the edges of your parts. When coating parts of different heights, using "vertical zoning" will only turn on those guns that have parts in their spray areas. The increase in the application efficiency of your spray system and reduction in picture-framing on your parts lower your operating costs.

Often, when visiting customers, I find that the first-, second- and third-shift operators can't seem to agree on the system settings. Different people on your line may have different ideas on how the system should be operated. And, although the attempts to optimize the system's performance are highly encouraged, the changes in system settings from shift to shift or operator to operator introduce variations to the applied coating cost and finish quality. Many digital control systems feature password protection of your system settings. Thus, to avoid variances and to have better control over the system's performance, different levels of password protection can be established in which only supervisors can be authorized to change certain system parameters.

Digital control systems can also incorporate a closed-loop control of the airflow to the powder pumps. Powder output of a conventional powder feed system is prone to variations, resulting from, among others, upstream pressure changes in your compressed air system. A digital system with closed-loop airflow control continuously monitors itself and provides 100% repeatable airflow output to the pump. The high degree of repeatability of the system outputs can significantly reduce the variations in your applied coating cost.

Another tangible benefit to your operation can result from using the different gun/system purge options offered by some digital control systems. At times, when the guns are turned off during a line gap or conveyor stop, powder can settle inside the gun and powder feed hose. When the guns come back on, a surge of powder out of the guns can occur, producing rejects. To avoid this, purge functions can be built into a digital control system. For example, the powder inside the hose can be expelled with a purge if there are no parts in front of the guns. Or, if the spray system is interlocked with your conveyor and the parts are in the spray area, a gradual ramp-up of the powder output will prevent the surge, minimize rejects and lower the cost of quality.

If you are getting the most out of your existing system-great! However, what if your system capabilities where to expand? Would you be doing even better? Examine your system, talk to your equipment vendor, and see if some of the digital system capabilities mentioned above can produce tangible savings in your operation.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!