Advanced UV Powder Coatings

Ultraviolet (UV) powder coatings combine the advantages of thermosetting powder coatings with those of liquid ultraviolet cure coating technologies. The difference between standard and UV powder coatings is that in UV systems, melting and curing are separated into two distinct processes. Upon exposure to heat, UV curable powder coating particles melt and flow into a homogeneous film that is cured only when it is exposed to UV light. The most popular curing mechanism used for this technology is the free-radical process, in which UV light activates photoinitiators in the molten film to form free radicals that initiate a polymerization reaction involving resin double bonds. The final coating appearance and performance depends on the selection of resin systems, photoinitiators, pigments, fillers and additives, as well as on the powder coating process conditions and curing parameters.

Figure 1. Patents on UV powders over the past 30 years.

Figure 2. Heating/curing profile applied on MDF.

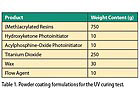

Table 1. Powder coating formulations for the UV curing test.

The Polyester/Epoxy Advantage

The combination of a methacrylated polyester and acrylated epoxy resin provides an interesting blend of properties to the cured film. The polyester backbone results in good resistance in weathering tests, while the epoxy backbone provides outstanding chemical resistance, as well as improved adhesion and smoothness.To test the resulting finish, a methacrylated polyester and two blends of the same polyester and an acrylated type-3 epoxy resin based on bisphenol-A and epichlorhydrine9 were formulated into UV powder coatings using the recipe shown in Table 1. The heating/curing profile used in the test is shown in Figure 2.

Medium infrared radiation was applied first to melt the powder particles. Film forming was achieved in a second zone by applying convection heat, and curing of the film was achieved in a third zone by irradiation with UV light. UV irradiation always increased the surface temperature, but the measurements clearly indicated that the temperature just beneath the surface was well controlled and was limited to 110°C for the entire cycle of less than three minutes - a very short period of time compared to the times required for thermosetting powders cured around 120°C.

Table 2. MEK rubs of UV-cured polyester/epoxy blends.

The choice of phthalic acid derivative (PA) in the synthesis process yielded methacrylated polyesters with a similar Tg but with different melt viscosities. When blended with acrylated epoxy resins, polyesters with a high Tg and a low melt viscosity produced a binder with the lowest melt viscosity for optimum coating smoothness, as shown in Table 3 (p. 28).

It is important to note that powders incorporating binders with hydroxyketone-based photoinitiators can experience some caking during storage and some fusion bonding during transportation from feeders to spray guns. However, if these limitations can be controlled through air-conditioned work zones, micronization of the powders, chilled mills or other means, such systems can produce smooth films.

Combining polyester and epoxy chemistries in UV powders yields smoothness, adhesion and chemical resistance in the resulting finish.

Expanding Applications

Blends of specific polyesters and epoxy resins have permitted the development of smooth, high-performance finishes for wood, metal, plastic and toner applications.Wood. Smooth, matte clear coats have been successfully applied on hardwood and on veneered composite board, such as beech, ash and oak. The presence of the epoxy partner in the binder has boosted the chemical resistance of all the coatings tested.

An attractive market segment for the advanced UV powders is as a replacement for polyvinyl chloride (PVC) laminates on medium-density fiberboard (MDF) panels for the furniture industry. Combined polyester and epoxy structures have allowed UV powders applied on MDF to pass the norm DIN 68861 specification, including chemical, abrasion, scratch and heat resistance.8,10,11,12 However, the ratio of polyester to epoxy affects the results in accelerated weathering tests; the more polyester in the binder, the less yellowing of the coating. A compromise between UV resistance and chemical resistance or smoothness needs to be found if accelerated weathering tests must be used.

Table 3. Tg and viscosity comparison between resins for UV powders.

Plastics. When applied as protective clears on PVC tiles for resilient floorings or on sheet molding compound (SMC) panels for OEM applications, the polyester/epoxy combination yields UV powders with high levels of flexibility and chemical resistance.10 Abrasion resistance for matte clear coats is good; however, more work is required to achieve high-gloss clear coats.

Toners. A joint development with a toner producer revealed that (meth)acrylated polyester/epoxy blends used as binders for colored toners gave the required toner properties after melting and UV curing.

The UV curable powders have exhibited excellent adhesion and improved corrosion resistance on metallic substrates.

A New Finishing Option

Combining polyester and epoxy chemistries in UV powders yields smoothness, adhesion and chemical resistance in wood furniture, metal, plastic and toner applications. With these advanced UV powder coatings, finishing professionals in a variety of industries have a new option for achieving a high-performance finish with a rapid cure.References

1. A mixture of crystalline UV-PE and acrylic, US 6.384.102 (Cytec Surface Specialties).2. EP 0 585 742 (Cytec Surface Specialties).

3. EP 0 636 669 (DSM).

4. EP 0 286 594 (Vantico).

5. EP 0 410 242 (Bayer).

6. EP 0 667 381 (Vantico).

7. WO 02/100957 (DuPont).

8. K. Buysens and O. André, "UV Curable Powder Coatings for Wood: The Ultimate Solution?" Fatipec Congress, Sept. 9-11, 2002, Desden, Germany.

9. P.J. Flory, Principles of Polymer Chemistry, Chapter IX, Cornell University Press, Ithaca, N.Y., 1953, p. 347.

10. Y. Souris and K. Buysens, "New UV Powder Systems for Metal, Wood and PVC," Journal für ObenflächenTechnik, January 2001, pp. 24-31.

11. K. Buysens, "UV Curable Powder Coatings on Wood: Benefits and Performance," Paint & Coatings Industry, November 2001, pp. 60-66.

12. C. Zune and K. Buysens, "New Resins for UV Curable Powder Coatings - Wood Applications," Creative Advances in Coatings Technology, April 2-4, 2001, Nürenberg, Germany.

13. G.E. Booth and S.F. Thames, "Real Time Curing Kinetics and Crosslinking Efficiency of UV Curable Powder Coatings," International Waterborne, High-Solids and Powder Coatings Symposium, February 6-8, 2002, New Orleans, LA.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!