Catalysts' Role in Low-Gloss Hybrid Powder Coatings

In this study, the crucial role played by catalysts in the preparation of low-gloss hybrid powder coatings using a reactive additive (styrene maleic anhydride copolymer) is described. First, the reactions that occur during the cure of epoxy/polyester hybrid thermoset powder coatings are reviewed. DSC measurements on model mixtures and fully formulated powder paints reveal relative reactivities and the role of catalysis on the various reaction steps. The gloss properties of the coatings are found to be closely tied to the presence of a catalyst. Several approaches to preparing powder coating formulations that exhibit fast cure kinetics, low-gloss appearance and excellent properties are described.

This paper is adapted from work originally presented at the 2001 International Waterborne, High-Solids, and Powder Coatings Symposium.

Background

Gloss is a measure of the amount of light reflected from a surface at a given angle, and is expressed as a value between 0 and 100. Polished plate glass has a value of about 100, and a completely nonreflective surface has a value of 0. Low gloss coatings are typically measured as 60-degree gloss, although the 85-degree gloss is also sometimes used. The range of gloss readings are loosely divided into several categories, as shown in Table 1.The chemical and physical properties of most major classes of powder coatings cure to give a level, glossy surface. However, for aesthetic and functional reasons, it is often desirable to have a powder coated surface with a low gloss, or matt finish. In such cases, gloss control may be achieved through many different techniques, including the addition of inorganic fillers or organic waxes, the blending of powders of different reactivities or the use of certain reactive agents.

The choice of gloss control agent depends upon the level of gloss reduction desired and the chemistry of the powder coating. Fillers can give rough surfaces due to the protrusion of the fillers from the surface after baking, which disrupts reflected light. Waxes and other incompatible ingredients tend to segregate on the surface during baking, leaving circular voids or forming a film on the surface. The 60-degree gloss reduction of both fillers and waxes is limited to about 40. Blends of powders of differing chemistries/reactivities, as well as chemically reactive additives such as polycarboxylic acids or their acid salts are used to achieve low and matt finishes.

Low-molecular-weight styrene-maleic anhydride (SMA) resins are a family of anhydride and partial ester functionalized copolymers which have been widely used as gloss-reducing additives in thermoset epoxy powder coatings.2 Earlier studies suggest that a two-stage reaction process leads to the textures observed in low-gloss epoxy powder coatings containing SMA.1 In this mechanism, dicyandiamide (Dicy), another epoxy curative traditionally added to epoxy powder coatings, reacts at a different rate than the SMA curing agent, leading to two structural networks within the coating.1 In studies of a similarly reactive low-gloss additive, Lee et al3 observed low-gloss epoxy coatings during curing, and saw that the coarse surface morphology formed as the gel point of the coating was reached. After gelation, the surface roughness remained fairly constant even with further curing, although fine structure continued to develop past the gel point. This suggests that the low gloss texture is a consequence of morphology development during curing, and is not due to stress-induced texture development during the cooling of the powder coated surface.

This study explores the use of SMA resins as gloss-reducing additives in the more complex epoxy/polyester hybrid powder coating system. In these formulations, the reactivities between three components-the epoxy resin, the polyester and the SMA anhydride and/or ester-must be balanced to give the different curing rates which create the low-gloss morphology. The curing kinetics of the three possible two-component combinations are explored first by DSC. Using these results, powder coating formulations are prepared and analyzed. These studies uncover the characteristics of the polyester resin and the SMA resins necessary to obtain low-gloss epoxy/polyester hybrid powder coatings.

The Experiment

Materials. Epon 2002 (Shell Chemical) is a standard "Type 3" Bisphenol A epoxy resin with EEW 675-760. Albester 2240 (McWhorter Technologies) is a high reactivity carboxyl-terminated 70/30 polyester resin with an acid number range of 35 to 45 mg KOH/g and a viscosity (at 200°C) of 6000 to 8000 mPa.s. Albester 2250 (McWhorter Technologies) is an uncatalyzed version of Albester 2240. Crylcoat 7401 (UCB Chemical) is a high reactivity carboxyl-functionalized 70/30 polyester resin with an acid number range of 32 to 40 mg KOH/g and a melt viscosity (at 160°C) of 25-42 Pa.s. Crylcoat 7402 (UCB Chemical) is the uncatalyzed version of Crylcoat 7401. Resiflow P-67 (Estron Chemical) is a flow-control agent. Huberbrite #1 (J. M. Huber) is a grade of powdered barium sulfate suitable for use in powder coatings.SMA 3000 (Atofina Chemicals Inc.) is a low-molecular-weight copolymer of styrene and maleic anhydride in a 3:1 ratio, available in powder (P) and ultrafine powder (UFP) grades, with an acid number of 265 to 305. SMA resins designated as LO are free of acetophenone, the main odor component of SMA Resins. SMA 10840 (Atofina Chemicals Inc.) is a copolymer of styrene and maleic anhydride esterified about 65% with iso-octanol, having an acid number of about 240.

DSC Studies. Resin mixtures for DSC analysis were dry blended by grinding in a coffee mill for 5 minutes. The powders were analyzed on a TA Instruments DSC 2920 instrument, using a heating profile of 10°C/ min.

Powder coating formulations. All formulations are given in phr (parts-per-hundred resin), where the mass of "resin" (epoxy + polyester) totals 100 and all other ingredients are given as a fraction of this mass. Formulations were prepared on a 1-kg scale, with premixing via a "bag-shake," where the ingredients were simply shaken together in a bag. After premixing, the blend was passed through a lab-scale 50 mm twin-screw APV extruder. Unless stated otherwise, all formulations were prepared under high-shear conditions at 400 rpm with a rear-zone temperature of 100°F and a front-zone temperature of 175°F. After cooling, the resin blends were ground in a hammermill and passed through a 140 mesh (105 micrometer) screen. Test panels were sprayed using an electrostatic spray gun to a dry film thickness of 2.0 ± 0.2 mils and cured in an oven at 350, 375 or 400°F for 10 minutes; at 375°F for 15 minutes; or at 300°F for 20 minutes.

Physical testing. Panels were evaluated for 60-degree gloss, forward impact resistance, reverse impact resistance, crosshatch adhesion and solvent resistance. Gloss values were measured using a BYK Micro-Gloss 60-degree meter with a statistics feature; all reported values are the average of 10 readings. Impact resistance was measured using a Gardner impact tester and reported values are the highest level of impact at which the coatings showed no cracking. Solvent resistance was evaluated by rubbing a cotton ball soaked in methyl ethyl ketone (MEK) back and forth over the surface 50 times. After drying, the coating was inspected for any changes in appearance. A ‘pass' rating indicates no visible change, while a ‘fail' indicates that the film was completely removed. A rating of ‘slight softening' was given when the coating became softer with a visible change in appearance. ‘Softened' indicates more severe swelling, where a significant amount of the coating came off onto the cotton ball.

Chemistry Of Polyester-Epoxy Hybrid Formulations

Polyester/epoxy hybrid powder coatings contain both epoxy resins and carboxyl-terminated polyester resins, and may also contain a catalyst to drive the curing reactions. Polyester producers market "high reactivity," "active" or "low-temperature curing" polyester resins that have been admixed with catalysts during production.4 These catalysts are intended to speed the cure rate or to lower the cure temperature of high-gloss hybrid coatings. In this study, they are investigated to find if they aide in the cure of gloss-reducing additives.To understand the effect of catalyst addition on low-gloss hybrid formulations, we chose to concentrate on two SMA Resins (SMA 3000 and 10840), one epoxy resin (Epon 2002) and two families of 70/30 carboxyl-terminated polyester resins (Albester 2240/2250 from McWhorter and Crylcoat 7401/7402 from UCB). These polyester resins are catalyzed and uncatalyzed versions of the same materials, allowing us to examine the use of precatalyzed polyesters, to add external catalysts to uncatalyzed formulations and to perform control experiments.

DSC Curing Studies of Epoxy/Polyester/SMA Formulations

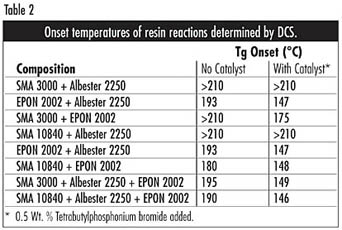

Differential scanning calorimetry (DSC) is a powerful tool for studying the kinetics of curing reactions.6 A variety of kinetic data may be garnered from DSC traces acquired in isothermal or dynamic mode, including the enthalpy of curing, the length of time to cure at specific temperatures, the temperatures at which curing begins or exhibits a maximum in the curing exotherm under specific heating rates, and the extent of cure at certain conditions. When similar systems are examined under identical heating rates, the temperature at which curing begins can be utilized as a comparative measure of cure rates. Powder coating or other crosslinking formulations that cure at lower temperatures on the DSC will probably be found to cure more quickly or at lower temperatures under application conditions.Samples of the mixtures of two of the three resin components (catalyzed and uncatalyzed) and fully formulated hybrid powders were analyzed via DSC at 10°C/min. The curing onset temperature (To) and temperature of the maximum exotherm (Tmax) were measured for each sample (see Figure 2 for a typical trace). This onset temperature data is compiled in Table 2.

These DSC studies indicate that all reactions are slow in the absence of an esterification catalyst, although the reactions of the carboxylic acid functionalized SMA resin (10840) occur at a lower temperature compared to reactions of the anhydride functionalized SMA resin (3000). The catalyst has the most pronounced effect on the reaction between the SMA resins and the epoxy resin. Based on these results, we looked at powder coating formulations based on precatalyzed polyester resins.

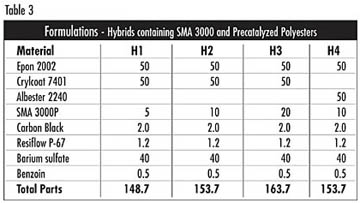

SMA 3000 Hybrid Formulations With Precatalyzed Polyesters

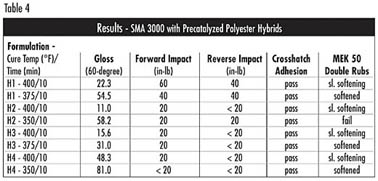

Two families of carboxyl-terminated polyester resins were chosen for this study: Crylcoat 7401 and 7402; and Albester 2240 and 2250. All resins are of the 70/30-type, with Crylcoat 7401 and Albester 2240 containing catalysts. Precatalyzed formulations containing SMA 3000P are outlined in Table 3. All formulations were prepared as outlined above.The results from formulations H1 to H4 are summarized in Table 4. All coatings were found to exhibit poorer solvent resistance than comparable epoxy formulations, which is typical of hybrids in general, probably due to a lower crosslink density. Curing at 400°F or higher is recommended, as higher glosses and reduced physical properties are obtained at lower curing temperatures. It appears that these high temperatures are required to allow curing to be as complete as possible. The lowest glosses were obtained using the Crylcoat resin with 10 parts of SMA 3000.

However, it was also found that the active forms of the polyester resins contained phosphorus (Crylcoat 7401 = 362 ppm P, Albester 2240 = 139 ppm P), while the uncatalyzed resins did not (Crylcoat 7402 = 6 ppm P, Albester 2250 = 6 ppm P). Therefore, the effect of gloss reduction by adding phosphorus catalysts to otherwise high-gloss formulations was investigated.

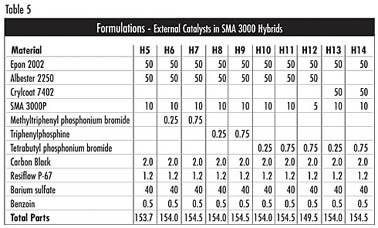

SMA 3000 in Hybrids-Addition of External Catalysts

In addition to using precatalyzed polyester resins, it is possible to add catalyst independently. This should give formulators greater control over the properties and cost of their coatings, although a little more development work is required to optimize the formulation. Three different catalysts were tried at different levels in hybrid formulations containing Crylcoat 7402 and Albester 2250. Formulations shown in Table 5 were prepared as previously described.

Hybrid Powder Coating Formulations With Acid Functionalized SMA Resin (10840)

A number of formulations containing an acid functionalized reactive additive, SMA 10840, were prepared. The same resins and catalysts were used as in the SMA 3000 formulations, substituting SMA 10840 for 3000. These formulations are shown in Table 7. Characterization of formulations I to V is summarized in Table 8. Surprisingly, all powder coatings prepared with SMA 10840 exhibited high gloss. However, the coatings exhibited good solvent resistance indicating that the coatings were fully cured. From the DSC studies, it is clear that SMA 10840 reacts more readily with EPON 2002 than does SMA 3000. This is probably due to there being two reactive pathways available for the 10840 resin: reaction of the 10840 carboxylic acid groups with the EPON epoxy groups, and reaction of the 10840 anhydride groups with the EPON alcohol groups. Therefore, the overall reactivity of 10840 with EPON is similar to that of the polyester resin with EPON. This could explain the difference in matting behavior exhibited by SMA 3000 and 10840, since it is believed that different cure rates are needed to set up the two-network morphology needed for a low-gloss finish. As such, SMA 3000 and EPON cure at a different rate than the polyester and EPON, giving a low-gloss finish, while 10840 and the polyester cure at similar rates with EPON, giving a uniform, single-phase high-gloss surface to those powder coatings.

Conclusions

SMA resins work as reactive gloss-reducing agents in epoxy/polyester hybrid powder coatings through formation of a two-phase micro-texture morphology. Model studies indicated that catalysis of the SMA resin anhydride/epoxy resin alcohol reaction is necessary to develop the proper morphology during curing to give a low-gloss surface. The catalyst can be present as a component of the polyester resin, or can be added separately to the powder paint formulation. Phosphonium salts were found to be highly effective in producing low-gloss powder coatings, and tetrabutylphosphonium bromide is particularly recommended as a catalyst for use at 0.25 to 1 phr in these types of formulations.Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!