Wet/Uncured Paint and Coating Removal

With two U.S. locations, the metal manufacturer/decorator is a safety-conscious and employee-oriented organization, so its management was concerned about serious accidents that could have been caused by its use of methyl ethyl ketone (MEK) to remove wet/uncured paint from its equipment and parts. MEK has excellent wet and uncured paint removal capabilities but is highly flammable, hazardous and unfriendly to the user. MEK was being used in large quantities as the primary wet/uncured paint remover on ferrous and nonferrous paint line equipment and parts. With its flashpoint at 21°F, MEK was regularly applied to surfaces that were considerably warmer than its flashpoint, thereby presenting the constant risk of a flash fire at any time during use.

Fine Organics says its goal was to alleviate its customer's safety problem by providing a replacement product that had a significantly higher flashpoint and that performed as well as MEK in removing the solvent-based wet/uncured paint from paint line equipment and parts. Fine Organics developed a proprietary solvent blend replacement product that has a flashpoint of 110°F, which is 89°F higher than MEK's flashpoint. In addition to performance and flashpoint considerations, the formulator was determined to develop a replacement product that provided value-added features and benefits that improve user friendliness and environmental conditions. In order to accomplish this, the research and development team and its sales and marketing department worked closely with the customer who provided multiple paint samples, including a range of polyurethanes, epoxies, acrylics and fluorocarbons in several different colors.

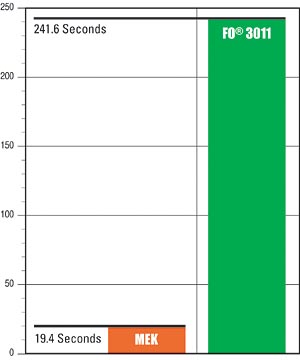

After the R&D team determined that the replacement product removed wet/uncured paint as effectively as MEK, the formulator provided the metal manufacturer with a material safety data sheet (MSDS) and then gained approval to proceed with field testing. The field test was to be conducted during color changes on the paint line equipment and parts. The basis of the field test involved the comparison between FO3011 and MEK on wet/uncured paint removal. Fine Organics submitted a 55 gal drum of the replacement product for the field test, which lasted two full weeks. Multiple color changes were performed by the customer with the new product used as the primary paint remover for a range of wet/uncured paints. The new product was used in a flush application during these color changes. To accomplish the desired paint removal results, the paint pumps were disconnected from the paint source and reconnected to the test drum of product, which was then pumped through the paint line into the paint pan receptacle, saturating it while the paint application rollers were turned on to pick up the blended solvent compound and remove the paint from both the pan and the rollers. Upon completion of this flushing process, the paint processing equipment and parts not involved in this process were cleaned with the replacement product via pouring, swabbing or spray, depending on the configuration of the parts and equipment. Other pieces of equipment and parts were wiped with a clean cotton cloth until all paint residue was fully removed. The product field testing was successful and the metal manufacturer determined that the replacement product performed as well as MEK, and made the transition to FO3011 as its primary paint remover.

In addition to higher flashpoint - which significantly reduced the possibility of flash fires - and paint removal capability, the replacement product provided the metal manufacturer with advantages such as a less volatile product, which results in less evaporative loss and consumption of product.

Because less of the replacement product is consumed, the customer reports that it has reduced its VOC output. In addition, the replacement product can be recycled more efficiently than MEK, resulting in improved environmental conditions and cost savings. The customer reports that it recycles the FO3011 three times and is used effectively each time to remove wet/uncured paint. Typically, MEK can be recycled once to remove wet/uncured paint. The replacement product due to its reduced volatility is considerably more user friendly, as it does not emit aggressive fumes that can be irritating to the skin and cause breathing problems.

Wet/uncured paint and coating removal remains an important part of industrial production for many metal decorators in getting their finished products to market. FO3011 is designed to be a safer and more environmentally friendly substitute for MEK and other highly hazardous and flammable ketones commonly used in the paint and coating industry for multiple purposes.

For more information, contact Lew Goldberg, national sales manager, Fine Organics Corp., at 973-202-5306 or 800-526-7480, ext. 204, or via e-mail fosales@aol.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!