Custom Coater Finds Simple Solution In Disposal-Free Pretreatment

VanDyk considered his options and decided to set up a batch style powder coating system that could provide the same flexibility and quick turnaround of his welding operation. One of his two target customers came through and placed orders with him that required coating.

The system includes a cleaning station, a batch style powder booth, a powder spray system, and a cure oven. The largest part that they can process is 3' x 4' x 7' long. Smart applies mostly epoxy/polyester hybrids, urethane polyesters and TGIC polyesters from DuPont Powder Coatings and IVC. Each station has a cycle time of approximately 20 min. When the workload demands it they can use one person at each station. If the workload is light it is possible for one person to run the entire system.

The company considered the various chemical and mechanical cleaning methods available and found problems with most of them. Sand or grit blasting is often used to prepare parts prior to powder coating application. Smart rejected blasting because the equipment is expensive and some of the sheet metal parts that they needed to coat would not withstand the blast pressure. Also, blasting alone does not passivate the metal surface or add a conversion coating for corrosion resistance. Most dip and spray cleaning methods required mixing of chemicals, multiple stages of treatment and some discharge of the byproducts of the process.

Plaforization, a product supplied by Carpenter Chemicals of Alexandria, Va., provided a one-step cleaning and phosphating process that required no mixing, no special controls and no discharge of wastewater. The solution is a mixture of special fluids with a resin and phosphating chemicals that applies a thin coating of an inorganic phosphate made from the substrate metal (iron phosphate on steel, zinc phosphate on galvanized, for example), sealed by a polymer. It is applied at room temperature in a single step with no rinsing. It produces no liquid or solid waste, it does not require expensive equipment and it is simple to use. As material is consumed, it is replaced with fresh material. The contents of the tank remain effective by filtering out solids, so the tank does not need to be drained. One gallon of the material can treat approximately 1,200 to 1,600 ft2 of metal.

The resin can absorb up to four times its weight in oil, which represents 14 gm/100 ft2 of oil on the metal surfaces to be cleaned. Since typical oil levels on cold-rolled steel are around 2 to 3 gm/ft2, the capacity of the polyphosphate seal to capture the unwanted oil is more than adequate. Parts with very heavy oil concentrations (greater than 14 gm/100 ft2) can be treated if the amount of metal processed is limited to a relatively short run. In other words, it is the average of oils that must be below the 14-gram limit.

The solution is agitated in the tank with eductors or venturi nozzles to facilitate removal of particulate through the filter unit. Tanks and circulation systems must be built of stainless steel because the Plaforization chemistry does not react with stainless steel. The tank can also be built with a false bottom so that larger metal particles and parts that fall into it can be easily removed. It is important to provide adequate exhaust around the tank to remove chemical vapors from the plant to atmosphere.

At Smart Manufacturing, parts are dipped in the cleaning solution for approximately 90 sec and then hung to drain and air-dry for 20 min before being placed inside an oven for 20 min to complete the drying process.

"During our first year of operation we powder coated approximately 100,000 tubes that were 20" long x 1.5" and never had a problem with pretreatment quality," says VanDyk. "Our customer had the least amount of rejects in their history and therefore I am very pleased with the Plaforization process." They are able to treat steel, cast iron, zinc-coated steel and aluminum in the same solution with good adhesion properties. Plaforization does not provide the extended corrosion resistance that would typically be required for some products that are used in some outdoor applications where high corrosion resistance is important, but performance is typically in the 300- to 500-hr salt spray range, equal to more traditional iron phosphate processes.

Like any chemical cleaning process, Plaforization must fit the process needs of the customer, and the products to be processed. The soils likely to be present on the part surface must be ones that Plaforization can handle (for example, Plaforization is not a rust or scale remover). Oils must be within the type and quantity range of the chemistry so that they can be effectively removed from the surface without adverse impact on the performance of the chemistry. Parts testing should be done to confirm that the oils present on the part are within the profile.

Like any process, there is not one size fits all. But Plaforization provides a unique and cost effective way to clean and treat multiple metals in various types of operations that is hard to beat. In addition to batch operations like Smart Manufacturing, Plaforization is used in larger operations, including an in-line dip process for munitions manufacturing and several in-line flowcoat operations.

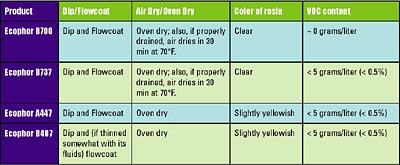

The newest product is Ecophor B700. It has the best coverage per square foot because its low vapor pressure and high boiling point ensure that evaporation basically does not occur until the parts are placed in the oven to dry. Therefore, virtually all the product not actually used on the part is returned to the tank during drip-off. B700 also uses a new resin that is clear, rather than the slight yellowish cast of the A447 and B407. That is only important for those few users that use a bright white topcoat where a slight and find a little of the yellow tinge may telegraph through the coating.

Ecophor B637 and A447 are essentially the same product, except that B637 uses the new resin. These two products, which have a somewhat lower flash point and higher vapor pressure than B700, can therefore be air dried in a batch process in which there is time to allow 30 min or so after drip-off for room-temperature drying. It is recommended in batch operations where in-plant temperature does not generally rise above 85°F.

Ecophor B407 is a specialty product designed to give up to 72 hr of uncoated salt spray resistance, which it accomplishes by putting on a somewhat thicker seal. It is best used in a two-step process with one of the other Plaforization products as the first step, because the other products have greater oil removal capacity.

At Smart Manufacturing, the primary concerns were waste disposal, simplicity, flexibility for different substrates, low capital costs, low operating costs and limited space requirements. The Plaforization process fit these needs perfectly.

The venture into powder coating has worked out very well for Smart Manufacturing. Although they are open to expansion, possibly an automated in-line flowcoat installation, they are doing well with the flexibility of the batch operation for now.

For more information about this process, call Carpenter Chemicals LC at 866-683-1570 or 703-683-1570, or visit www.cc-lc.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!