Power Treatment - Plasma for the Perfect Design

The Power of Plasma

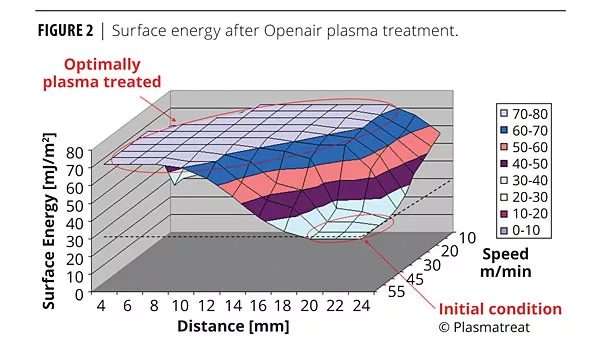

Openair plasma-jet technology, developed by Plasmatreat GmbH in 1995, is a substitute for the wet chemical pretreatment process. This process, which is used worldwide today in industrial applications, allows for microfine cleaning, strong activation and nanocoating of material surfaces, which results in long-time stable adhesion of paints and adhesives. The technology works under normal ambient air conditions, i.e., it needs no costly intensive vacuum chamber as in low-pressure plasma processes. Also this plasma method works at zero potential, which largely expands its application possibilities. Trials at Plasmatreat have demonstrated that surface energy values of over 72 dyne are achievable when pretreating plastic materials with Openair plasma. The result: not only can previously incompatible substrates be bonded, but also adhesion of water-based adhesive or paint systems on very adhesive-resistant surfaces becomes possible.

Since 2007 the Openair plasma process has been in use by GfO Gesellschaft für Oberflächentechnik AG, a subsidiary of the Nanogate Technologies Group, Germany. Here, hundreds of thousands of display fascias a year are treated with the plasma prior to coating. Recently, GfO began employing this plasma technology for a new product that has never been manufactured in this form before – a car key from Volkswagen.

Stringent Requirements

In 2009 Volkswagen was seeking a never-before-seen optical surface effect for its new car key design. The paint was supposed to be not only “piano black” (i.e., a deep, high-gloss black), but at the same time transparent, and had to provide the best scratch and impact resistance the world market could offer. A perfect paint appearance and long-time stable adhesion were given topmost priority. GfO, located in Schwäbisch Gmünd, was given the order for this world-debut product. For GfO, the order meant making the impossible possible, and doing it within six months. In addition, readiness for series production had to be ensured.

New Injection Molding Solution

The unpainted top and bottom shells of the key consisted of a polyamide PA 66 GF30 (reinforced by a 30% glass fiber portion). This was the material that had been chosen to meet the high-impact strength requirements including, among others, the successful passing of drop and fracture tests. It was also required that the extended key bit be unable to break out of the shell at a specific load. The developers were quite aware that glass fiber is actually not suited for high-gloss coating, and certainly not by applying a one-component nano paint system in the 10 µm range, which was the maximum film thickness of the paint to be applied by GfO.

Norbert Weiss, Sales Manager at GfO, comments, “It happens that glass fibers ‘are standing up’ in the injection molding process and make their way up to the paint finish. The consequences are pimple-like irregularities and immediate scrapping.” In order to enable painting of the key shells according to specification, a decision was made to change the plastic manufacturing process. Instead of using the conventional injection molding method and the usual grain on the key surface for concealing irregularities, the shells were produced by applying a MuCell injection molding process, which is a physical foaming process for thermoplasts. With the aid of this process, not only could a perfect reproduction of the mold surface be realized, but the usual sink marks and irregularities could be avoided as well. But even here a problem arose: the foaming process left visible streaks on the workpiece, and the surface after injection molding was anthracite rather than deep black in color.

The Challenge

It was obvious to GfO that two proven methods could be relied upon. First, there was their own Sicralan inkjet process, a unique and patented one-component nano paint system for selective, transparent and high-gloss scratch-resistant coatings. Second, there was the process-secure, fully trusted Openair plasma technique for ensuring a 100% homogeneous paint gradient and strong, long-time stable adhesion. The client demanded that the product meet all the test specifications in the automotive manufacturers’ test catalogs, including climatic change tests, hydrolysis tests, media, acid and cream tests, and the adhesion cross-cut test. But over and above all these tests, Volkswagen demanded yet another specific test: the highly abrasive drum test.

Adhesion Through Plasma Activation

Without the high degree of activation received by the polyamide in the plasma process, wetting problems would arise and make coating impossible. Dr. Alexander Knospe, Head of R&D at Plasmatreat, explains the chemical processes, “Plasma pretreatment strongly increases the surface energy of the plastic material since polar groups, such as hydroxyl functionality, are formed on the surface. In this application, not only complete surface wetting with a given paint or adhesive is improved, but also the creation of a covalent bond is made possible on the surface.” The results are homogeneous paint gradients and long-time stable adhesion of the scratch-resistant coating even under the highest stresses. It should be noted that the typical rise in temperature of a plastic surface during treatment is less than 30 °C.

Conclusion

The test results confirmed the trust placed in the high-tech technologies: a quick steel wool test did not harm the Sicralan MRL UV high-performance surface. Another difficulty, namely stopping the pressure of the scratch-resistant coating in a descending radius − unmasked in a design joint − was also mastered. Thanks to the plasma pretreatment, the cross-cut test passed with the best possible value, Gt0 (no adhesion pull-off), and even when exposed to the drum test, the coating would not separate. The other tests provided an equally positive result. The streaks disappeared, the surface was immaculate, deep black in color and high gloss. The world’s first radio car key with this optical effect and of this quality, destined for the Phaeton car model, could go into production on time. n

For more information on plasma technology and systems, visit www.plasmatreat.com. For information on plastic finishing/key manufacturing, visit www.gfo-online.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!