Silicone Versatility

Anti-Flooding and Anti-Floating Titanium Dioxide Dispersants

Flooding and Floating

Silicones are well known for their surface activity and the benefit this brings to inks and coatings. The versatile architecture of these materials means they can deliver a wide range of properties, such as slip, haptics, wetting and leveling. These silicone materials are typically low molecular weight and non-reactive, in order to ensure they migrate quickly to the ink or coating surface to do their job.

While silanes are known for pigment and filler dispersion, silicones are not. Non-silicone products for this benefit are typically organic dispersants such as polycarboxylic acid polymers, or polyurethane polymers.

Floating is a phenomenon that occurs in TiO2-based white, pastel and grey formulations, and is caused by the pigments and fillers present separating from the organic resin binder and one another in the liquid phase due to incompatibility. This incompatibility, due to density differences and pigment and filler surface treatments, leads to the pigments rising to the surface of the paint, causing in-can instability (Figure 1).

When pigments and fillers in paint are not stabilized, you can also experience separation and concentration of one pigment at the surface of the film upon drying. This non-uniform pigment concentration throughout the thickness of the film is known as ‘flooding’. This may result in a failure to develop the intended color (Figure 2), or differences in color may be seen depending on film thickness or application technique.

Silicone Pigment and Filler Dispersants

In theory, an effective pigment treatment to prevent flooding and floating needs to be able to interact with the pigment or filler surface and achieve excellent compatibility with the organic resin binders. Here we review how the silicone structure impacts anti-flooding and anti-floating performance, and demonstrate how Dow Corning® 3 Additive gives excellent performance at low addition levels.

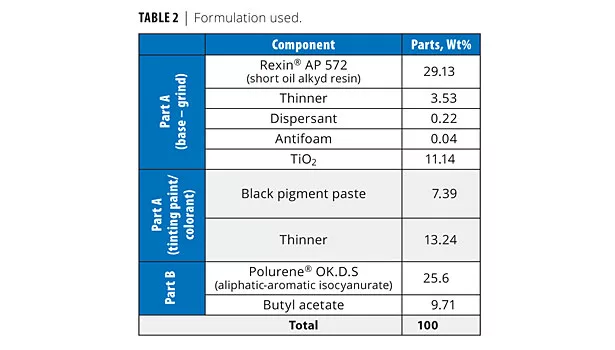

Table 1 shows a series of silicone-based products that were evaluated in solventborne formulations. Traditional organic dispersants on the market were used as benchmarks:

• A modified polyurethane (50% actives);

• An unsaturated polycarboxylic acid polymer + polysiloxane copolymer (50% actives).

Flooding and floating are particular issues in carbon black-based paint formulations, so here we present the anti-flooding and anti-floating properties of the given technologies in a 2K polyurethane solvent-based grey wood coating as an example of performance. In the first instance the materials were added into the base paint during the pigment grind stage. All materials were added at 0.22% by weight to the total formulation, equivalent to 2% of TiO2 solids (Table 2).

Performance

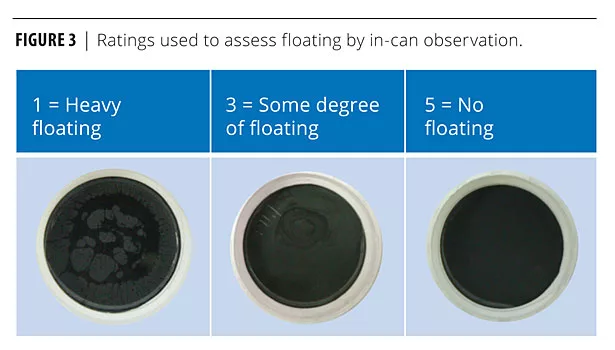

After production, the well-mixed paint was poured into a can and allowed to stand for 30 min. After this time the surface of the paint was given a rating between 1 and 5 according to the degree of pigment floating on the surface (Figure 3).

The traditional industry rub-out test was used to assess the flooding properties of the mixed paint. The paint was drawn down onto a LENETA chart and rubbed by finger. The color difference (DE) between the rubbed surface and unrubbed surface was measured spectrophotometrically; the larger DE value means heavier flooding.

If we first compare the performance of the silicone materials at different molecular weights, we can clearly see how this property influences performance. With the lower-molecular-weight surface-active additives, Dow Corning 67 and 57, we see little impact on anti-flooding and anti-floating properties. Adding the high-molecular-weight, reactive Dow Corning 3, we see excellent anti-floating and anti-flooding performance. This is more impressive perhaps when we consider that Dow Corning 3 is only a 10% actives solution and, therefore, the active silicone level in the paint is 10 times less than with other silicone solutions, making it highly effective at low concentrations.

If we then compare the performance of Dow Corning 3 to the organic-based pigment dispersants on the market, we also see that the high-molecular-weight silicone gives better anti-floating and anti-flooding results when added at the same weight % addition level to the formulation. We should, however, be mindful that price pressures in the market may require the formulator to use less pigment dispersant in their formulation. For this reason we tested Dow Corning 3 at a lower dosage rate versus organic solutions (Figure 5) and found that it keeps its high effectiveness even at very low dosage levels due to its unique chemistry. After reducing the dosage level to less than half of the original level, a high rating 4 for in-can floating was still achieved, and almost no change on flooding indicated by DE.

Post-Addition Performance

Although most effective in the grind stage, Dow Corning 3 additive also can be post-added to prevent floating and flooding. Why is this important? In some cases the formulator has no control over the quality of the base or tint paint they are using, and when formulating at a local level they may still see floating or flooding. This material will provide improvements in anti-flooding and anti-floating even when used as a post-additive, a feature beyond traditional dispersants on the market today.

To assess this post-additive performance, a traditional organic dispersant was used in the preparation of the base paint (Competitor 1 was used) – this is the control shown in Figure 6. Dow Corning 3 and Competitor 2 were then post-added to this control base paint at only 0.03 weight% based on the total formulation. Dow Corning 3 improved floating and reduced rub-out (DE) even at this low post-addition level. This post-addition performance allows for more flexibility in formulating.

How Does it Work in Theory?

It is hypothesized that the silicone resin wets the surface of the inorganic pigment/filler (e.g., titanium dioxide), where the reactive SiOH group then reacts to anchor it to the surface. Organic groups also present on the silicone resin backbone then act to compatibilize the treated pigment/filler with the organic binder. The pigments/fillers are stabilized due to steric hindrance provided by the high-molecular-weight silicone backbone and by low intermolecular forces preventing the flocculation of pigment.

Summary

While silicones can offer many benefits to the formulator, choosing the right chemistry for the right job is critical. Dow Corning 3 additive offers a high-molecular-weight, reactive material to the market that can improve paint consistency by preventing flooding and floating. Using this additive either in the pigment grinding or by post addition at a very low addition level, allows the formulator to achieve excellent cost-in-use performance.

For more information, visit www.dowcorning.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!