Novel Application of Fluorosurfactants

in Easy-Clean Architectural Paints

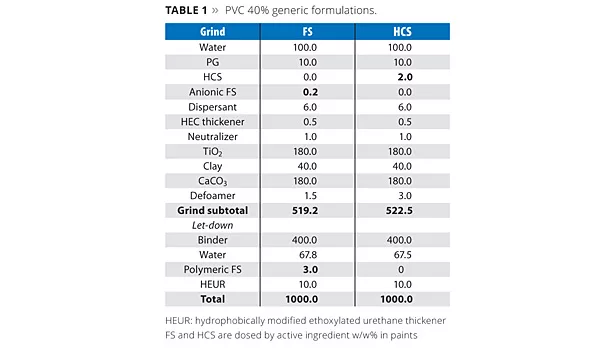

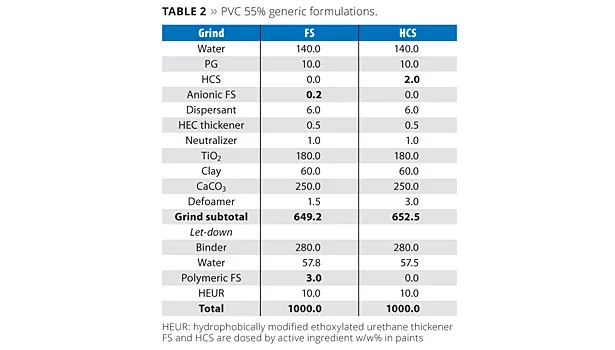

Results and Discussion

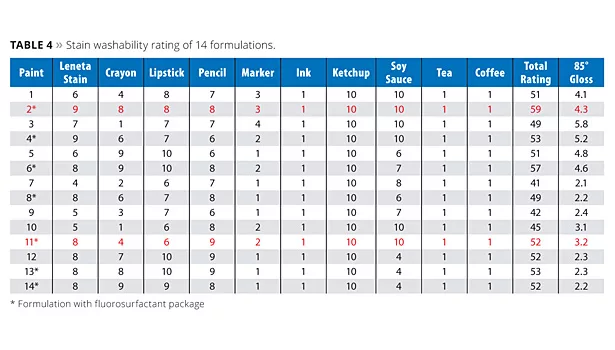

Stain Resistance and Washability

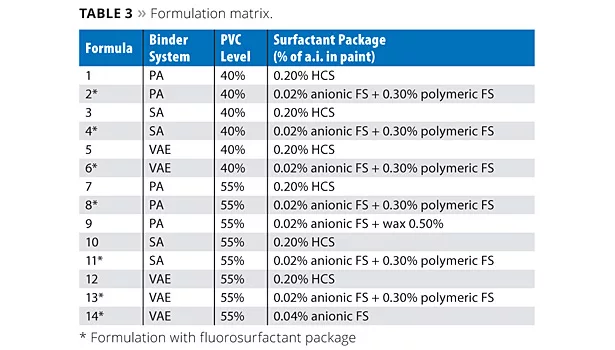

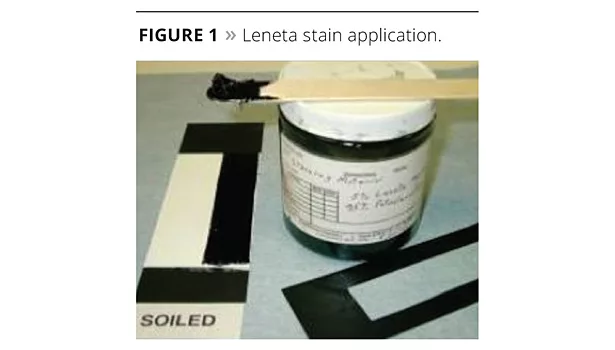

The stain resistance rating data of 14 investigated formulations is shown in Table 4. For hydrophobic stains like Leneta stain, crayon and lipstick, fluorosurfactants containing Formulations (2, 4, 6, 8, 11 and 13) showed better performance than HCS-containing Formulations (1, 3, 5, 7, 10 and 12). In the formulation group of 55% PVC and pure acrylic binder (7, 8 and 9), Formulation 8 with a FS package has a rating of 8, 6 and 7 for Leneta stain, crayon and lipstick vs. Formulation 7 with the HCS package that has a rating of 4, 2 and 6, respectively. Incorporation of wax in Formulation 9 did not significantly improve the performance.

For hydrophilic stains, the cleanability of marker, ink, tea and coffee was not significantly improved among all formulations. This confirms that hydrophilic stains are very hard to clean in low-gloss interior paints. The addition of FS has minimum impact on their cleanability.

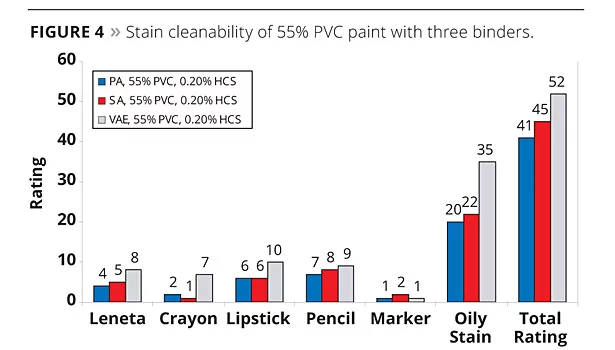

Effect of Binder Type

Formulations 7, 10 and 12 were formulated with pure acrylic, styrene acrylic and VAE binders and with 55% PVC and a HCS package. The total cleanability rating of all stains was 41, 45 and 52, as shown in Figure 4. The hydrophobic stain cleanability ratings were 20, 22 and 35. The VAE binder system showed better stain resistance performance than the other two binder systems in removing hydrophobic stains (Leneta, crayon, lipstick and pencil). However, the differentiation of the binders only delivers some degree of stain resistance. The formulation needs to be further optimized with respect to PVC level and surfactant packages.

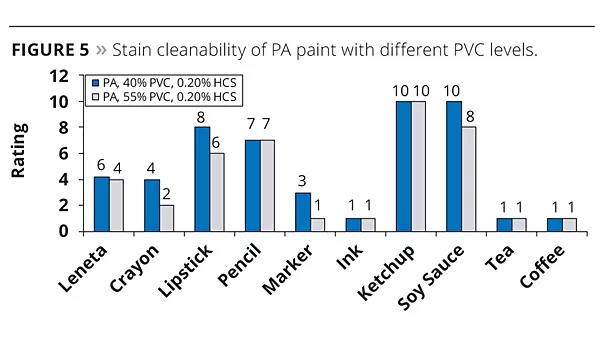

Effect of PVC

In pure acrylic binder systems with HCS, two PVC level formulations (40% and 55%) were tested for stain cleanability, and the data is shown in Figure 5. The results show that the stain cleanability rating of most stains declined with the increase of PVC level. Formulating a good easy-clean paint requires a minimum PVC level. When PVC is too high, the stain cannot be cleaned off the porous surface. Even a good binder cannot aid the performance as expected.

Effect of Surfactant

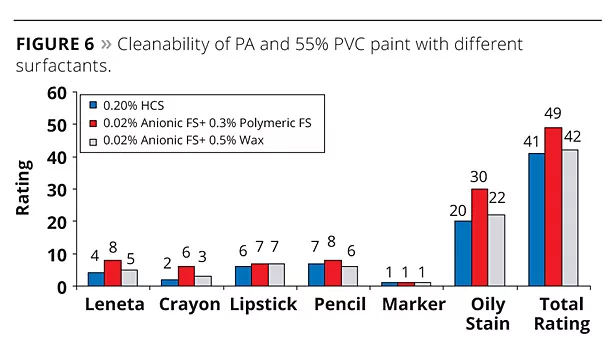

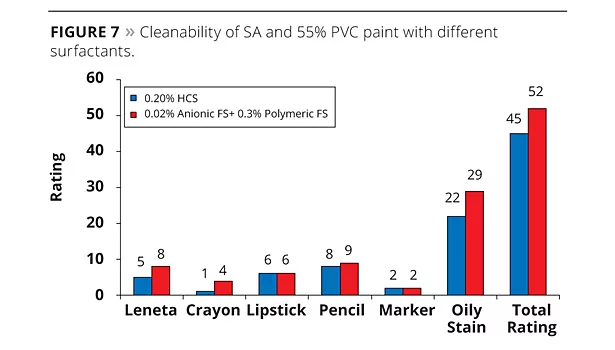

Two classes of surfactants were used to evaluate their impact on stain cleanability: fluorosurfactants and hydrocarbon surfactants. With a pure acrylic or styrene acrylic binder and a 55% PVC ratio, good oil-stain cleanability was achieved by the use of the FS package represented by Formulations 8 and 11, shown in Figures 6 and 7. For the PA system, Formulation 8, containing an anionic FS and a polymeric FS, significantly improved the oil-stain cleanability rating to 30 from 20 for Formulation 7. For the SA system, Formulation 11 with FS improved the oil-stain rating to 29 vs. 22 for Formulation 10. The combination of anionic FS and wax was less effective than the combination of anionic and polymeric FS in achieving oil-stain cleanability, shown in Figure 6. Anionic FS serves as a multi-functional wetting agent in the grind stage to provide superior wetting power with less foam. As a result, less defoamer was needed, which improves paint oil repellency. In addition, the polymeric FS added in let-down can further improve the cleanability when cured in the paint surface with low surface energy.

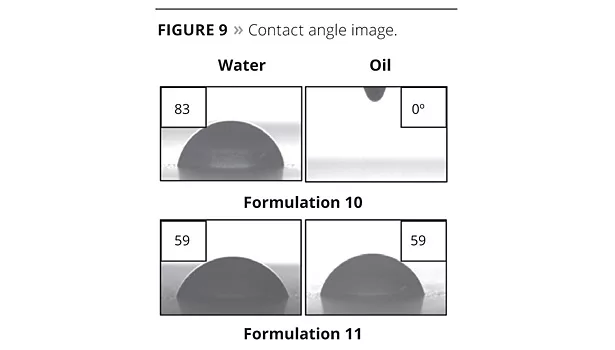

Water and Oil Repellency

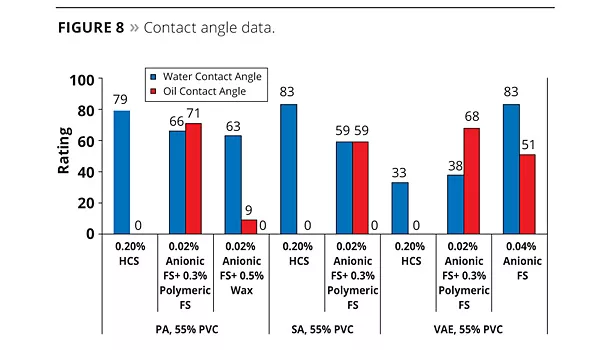

The water and oil contact angle data of formulated paints are listed in Figure 8. Water contact angle represents film water resistance, which is related to hydrophilic stain resistance and washability if surface porosity is not too high. In PA and SA systems, FS use slightly decreased the paint’s water contact angle. In VAE paints, FS use improved the paint’s hydrophobicity. The oil contact angles of formulations with HCS are near zero, which means the oily stain or oily chemical can easily wet-out on the film and will have negative effect on oil-stain cleanability. The oil contact angles of formulations with a FS package are significantly increased to more than 50°. Oil beading up on the paint film is demonstrated in Figure 9. The addition of FS can offer excellent oil repellency to paint films to resist oil stains. In the VAE system, the addition of anionic FS added both in the grind and letdown stage enhanced the water contact angle from 33° to 83°, which leads to hydrophobicity improvement in the VAE paint film.

Hiding Power

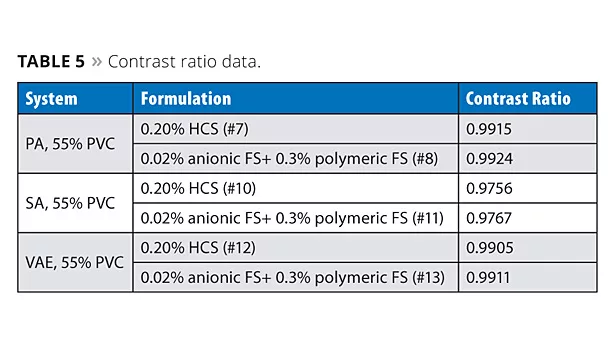

The contrast ratios of six paints with 55% PVC are listed in Table 5. Change in hiding power was not observed by altering the surfactant packages in specified PVC ratios and binder systems. The addition of FS did not affect the hiding power of the paint formulations. It is important to maintain hiding power when optimizing the formulation for other desired performance characteristics.

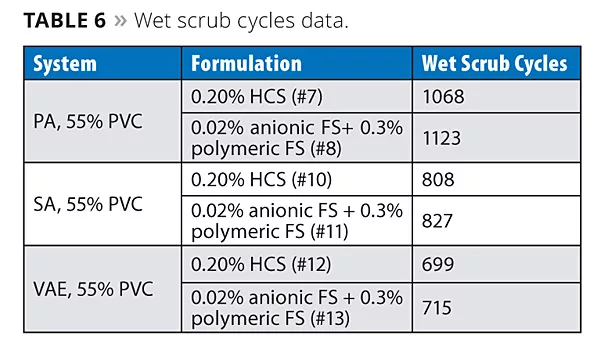

Wet Scrub

In this study, 55% PVC formulations were only checked for wet scrub resistance, since higher-PVC paints are more likely to have lower than desired scrub resistance. According to the data collected in Table 6, wet scrub resistance of PA, 55% PVC formulation is better than a SA, 55% PVC and a VAE, 55% PVC formulation. The scrub resistances mainly depend on the resin system and PVC level, and did not change significantly with the change of surfactant type. FS do not have significant impact on the wet scrub performance of paint.

Gloss

Gloss data of 40% and 55% PVC formulations in various binder systems are listed in Table 7. The gloss is mainly determined by PVC level. FS do not have significant impact on the gloss of paint.

Conclusions

Easy-clean properties of interior low-sheen paint are highly formulation dependent. Binder, PVC ratio and additive package all play important roles in final performance. Formulating an easy-clean paint is more challenging in high-PVC paints due to the high porosity of the paint film. Based on this study, the key points of formulation design are summarized below.

- For binder selection, VAE binders have better oil-stain cleanability compared with PA and SA systems. The lack of hydrophobicity of a VAE binder can be improved by the use of proper additives. For PA and SA systems, higher hydrophobicity can contribute to hydrophilic stain resistance and cleanability. The PA and SA system’s lack of oil stain repellency can be improved by fluoroadditives in formulation design.

- For PVC level, the increase of PVC ratio will decrease overall stain resistance and cleanability of the paint film. Easy-clean paints need to have the lowest possible PVC ratio while maintaining the sheen.

- With respect to the surfactant package, this study revealed that a combination of small molecule and polymeric FS with reduced defoamer additives has the best overall effect in formulating easy-clean paints. The FS can migrate and concentrate at the liquid-air interface due to the oleophobic nature of fluorocarbons. At the surface, the FS provides oil repellency to prevent the penetration of oily stains. In the grind stage, anionic FS can partially or totally replace the nonionic HCS, and thus reduce the need for defoamer. Since most defoamers attract oil and decrease oily-stain resistance, the reduction (or elimination) of defoamers will further enhance the oily-stain resistance and cleanability.

In summary, fluorosurfactants can help a well-designed interior flat paint to achieve overall easy-clean properties by adding oil repellency to the paint.

References

- Toshikazu, N. Development of a staining preventive coating for architecture, Progress in Organic Coatings1996, 27,173-180.

- Wagner, O.; Baumstark, R. How to Control Dirt Pick-Up of Exterior Coatings, Macromol. Symp. 187, 2002, 447-455.

- Giessler, S.; Just, E.; Storger, R. Easy-to-clean properties–Just a temporary appearance, Thin Solid Films 502, 2006, 252-256.

- Moilliet, J.L. Waterproofing and water-repellency, Eliser, Amsterdam, 1963, 52.

- Harding, T.R. J. Textile Inst.1950, 42, 930.

- Meng, J. Novel applications for fluorosurfactants in low VOC Coatings, Paint & Coatings Industry2007, 4, 84-88.

- Meng, J.; Guo, C. Novel application of fluorosurfactants in waterborne wood coatings, Paint & Coatings Industry2011, 10, 42-46.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!