Achieving Antimicrobial Protection in Coatings

Paint formulations contain standard industrial biocides for in-can preservation and stability. However, in-can preservatives do not necessarily offer dry film protection, as the dynamics of microbial protection change when the paint film dries. Furthermore, EPA registrations and regulations dictate the kind of antimicrobials that can be employed for dry film protection and claims that can be made from the use of these antimicrobials.

Formulating paints that have long-term dry film protection is challenging. For outdoor applications, variations such as the direction a painted surface faces can create dramatically different responses to how the paint is attacked by algae and fungus. A variable such as this, coupled with the wide variety of climate and geographic variables to which any paint product is subjected, increase the problem manufacturers face when attempting to warrant paint performance and durability. While indoor paints are typically subjected to narrower environmental fluctuations, variations in moisture, temperature, cleanliness (i.e., the degree of microbial infestation), age of construction and the type of substrate on which the paint is applied can all affect paint film integrity.

There are a number of laboratory-based test standards available for the determination of antifungal and antibacterial performance of dry paint films. These permit evaluation against standardized microbial challenges under predictable and reproducible conditions. A number of these methods may be specified by designers, architects or standards organizations, but it is important to understand what aspects of antimicrobial performance they are intended to evaluate. For example, in an antifungal test method such as ASTM G21, samples are placed horizontally in contact with a nutrient-poor salt agar and directly inoculated with a selection of fungal spores. Another ASTM standard, D3273, exposes samples to an airborne selection of fungal spores by vertically suspending them above an inoculated soil bed contained in a warm, humid chamber. These tests can express the antifungal attributes of dried coatings and paint films in drastically different ways, and coating formulators must, therefore, take care in selecting test standards that are most relevant to their end-use application.

Once performance of a particular antimicrobial technology is proven under standard laboratory conditions, assessment of prototype formulations under “real-world” conditions is prudent. For outdoor paints, there are ASTM standards that prescribe realistic outdoor exposures for expected use conditions. Factors that can impact performance such as surface angle to the horizon, the degree of surface condensation, the degrees of shade, acid rain and pollution, are taken into account by these methods.

Collaborative Study

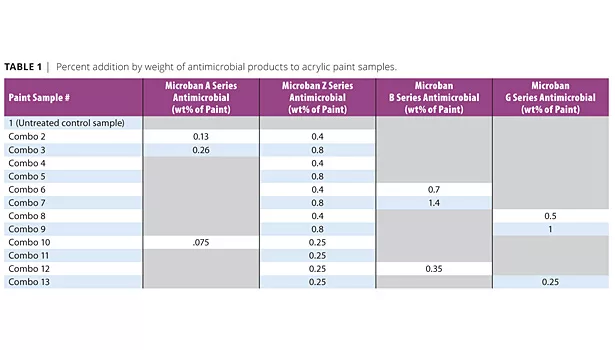

Microban’s many years of experience with coatings and films has resulted in a broad selection of antimicrobial solutions for treating paints that meet dried film antimicrobial performance under the EPA treated article exemptions. A recent collaboration with a leading international paint supplier investigated a series of Microban product offerings for dry film antimicrobial performance of interior paints. Twelve combinations of antimicrobial products were added at various levels to acrylic interior paints. Table 1 shows the addition levels of each product to base paint samples.

Samples for JIS Z2801 antibacterial testing were 3-mil thick, hand-coated films dried over polyester substrate. Samples for ASTM D3273 (antifungal) were dry, painted films applied to all exposed surfaces of 3.75 cm x 3.75 cm wood coupons.

Additionally, to simulate indoor cleaning of wall paint, samples of the same films were also tested for antimicrobial activity after undergoing a 10-min immersion and brush scouring using a 25% dilution of household bleach in water. These samples were rinsed with water and allowed to dry for 24 h prior to antimicrobial testing so as to eliminate any antimicrobial activity due to residual bleach.

Antibacterial test results both before and after cleaning are listed in Tables 2 and 3 respectively. These results show that all paint formulations containing a Microban additive demonstrated excellent suppression of both gram negative (Klebsiella pneumonia) and gram positive (Staphylococcus aureus) organisms before and after washing. Untreated paint film samples showed no significant reduction of either of these organisms.

Table 4 shows fungal activity of paint samples before and after washing (ASTM D3273). Fungal coverage on samples is reported on a scale of 0 (total fungal disfigurement) to 10 (total absence of fungal disfigurement). Fungal growth on wood coupons coated with Microban-treated paints was not observed, while significant mold colonization was detected on samples coated with unpreserved paint. Coatings with and without Microban antimicrobial are shown in Figure 1.

In summary, a wide range of additives can be incorporated into paint formulations that have potential to demonstrate excellent protection of the dry paint film from the destructive and disfiguring activity of common bacteria and fungi. These additive systems must be carefully chosen to be compliant with U.S. EPA regulations and their allowable claims. In addition, appropriate evaluation methods, both laboratory-based and under realistic exposure conditions, should be considered

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!