Nanomaterials Company Makes Dark Material Breakthrough

Surrey NanoSystems’ unique nanotechnology processing know-how has been used to deposit the world’s blackest material on lightweight, temperature-sensitive substrates. Its new super-black coating can be applied to optical instruments for space applications, to reduce reflections and increase sensitivity.

The breakthrough stems from the company’s patented process for manufacturing carbon nanotubes at low temperatures. In this application, the technology allows the company to fabricate super-black coatings on space-qualified lightweight aluminum components. The black coating material, which has recently been shown publicly at the 2013 UK Space Conference, sets a new record for the lowest reflectance in the infrared spectrum on materials such as aluminum, with a total hemispherical reflectance of less than 0.15% across the mid-infrared wavelength region.

Working in collaboration with the UK’s National Physical Laboratory and EnerSys’ ABSL Space Products Division, Surrey NanoSystems has demonstrated the robustness of its technology for space flight. In addition to its extreme absorbency, the material withstands space-launch shock and vibration, and exhibits excellent thermal stability. Further, it offers virtually undetectable levels of out-gassing, eliminating a critical source of contamination in sensitive imaging systems.

The material is manufactured by Surrey NanoSystems’ proprietary low-temperature carbon nanotube synthesis process, which can deposit vertically aligned nanotube arrays (or VANTAs) precisely and repeatedly on a range of temperature-sensitive, lightweight materials that are important to terrestrial, airborne and space applications.

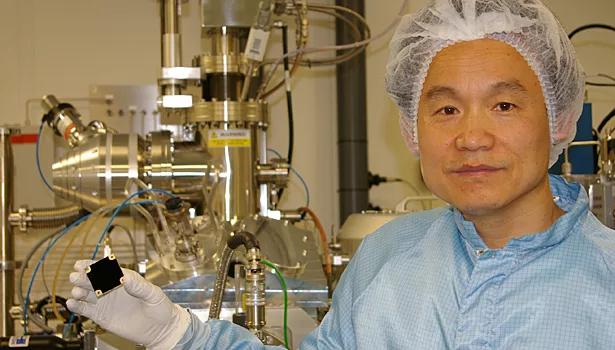

Other carbon nanotube fabrication processes usually require very high temperatures in the region of 750 °C, which can demand substrates made from thermally stable, heavier and costlier materials such as silicon, titanium or stainless steel. For application flexibility, the process can also deposit coatings on either flat or three-dimensional structures, and in precise patterns. The latter attribute is a spin-off from the company’s pioneering work in applying nanomaterials to semiconductor device fabrication. The dark material is fabricated on Surrey NanoSystems’ NanoGrowth®-Catalyst tool at the company’s R&D center in Newhaven, UK.

“The super-black material has been extensively tested and characterized by our partners NPL and ABSL,” says Surrey NanoSystems’ CTO Ben Jensen. “We now have a well-defined and highly repeatable process for making super-black coatings and are in discussions with a number of companies about applying it on commercial projects, as its combination of superior performance and European heritage simplifies the procurement process.”

For more information, visit www.surreynanosystems.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!