Dust Explosions

in the Powder Industry

In general, some 70% of dusts are explosive, and given an adequate ignition source and appropriate dust/air concentration, dust clouds can cause explosions. Combustible dust cloud explosions in powder handling facilities generally occur because of:

- The lack of proper understanding of the “ignition sensitivity” and “explosion severity” properties of the dust being handled, processed or generated;

- Failure to control the flammable atmospheres;

- Inability to identify and control all potential ignition sources; and

- Absence of effective measures for eliminating/controlling dust explosions.

Some materials will not present a dust explosion hazard due to their granular nature. However, during the processing of these materials, it is possible to create finely divided dust, which can be explosible. This applies to the operations where fine dust is intentionally generated (e.g., during milling) and/or unintentionally generated (e.g., during grinding, sawing, polishing or due to material attrition). Non-explosive materials such as sand or silica could become explosive if mixed with other explosible material (such as organic and/or metal dust) in adequate quantities. Hence, it is important to screen representative samples to determine if a mixture of material is explosive or not.

The concentration of dust in the cloud is important. The concentration of an explosive dust cloud resembles a dense fog. Although such concentrations are not normally expected to be present within processing buildings, explosive dust clouds are regularly formed inside the material handling/processing equipment, i.e., when bins are being filled, powders are being transferred, or dust is being collected in a dust collector.

The particle size of the dust is a property that influences the explosibility of the dust cloud. Powders include pellets (greater than about 2 mm), granules (between 2 and 0.4 mm) and dust particles (less than about 0.4 mm). The finer the particles the greater the surface area per unit mass, and thus the more explosive a given dust is likely to be. When the cloud is composed of a series of particle sizes ranging from fine to coarse, the fines play a prominent part in the ignition and the explosion propagation. The presence of dust should, therefore, be anticipated in the process stream, regardless of the starting particle size of the material.

The moisture content of a product will also affect the explosion risk. A dry dust contains less than 5% moisture. Dry dusts of small particle size will be more easily ignited and produce more violent explosions. Moisture within or on the particle surface reduces both the flame propagation ease and rate. However, it must be noted that moisture content in the range of 12-18%, as found naturally in many agricultural products, is not enough to render the dust non-flammable.

Conditions for Dust Explosions

A number of conditions must exist simultaneously for a dust explosion to occur.

- The dust must be combustible (as far as dust clouds are concerned, the terms “combustible”, “flammable” and “explosible” all have the same meaning and could be used interchangeably).

- The dust must be dispersed (forming a cloud in air).

- The dust concentration must be within the explosible range (above the minimum explosible concentration).

- The dust must have a particle size distribution capable of propagating flame.

- The atmosphere in which the dust cloud is present must be capable of supporting combustion.

- The available ignition source must have sufficient energy to initiate combustion.

The ignition sources that have been found to be the cause of the majority of explosions in dust handling/processing plants include welding and cutting, heating and sparks generated by mechanical equipment failure, sparks generated by mechanical impacts, hot surfaces, open flames and burning materials, self heating, electrostatic discharges, and electrical sparks.

The sensitivity of a dust cloud to ignition by different ignition sources should be determined through appropriate laboratory tests.

Assessment of Dust Explosion Hazards

A systematic approach to identifying dust cloud explosion hazards and taking measures to ensure safety involves several steps.

- Determine the dust cloud’s ignition sensitivity and explosion severity characteristics through appropriate laboratory tests on representative dust samples.

- Identify areas of the facility where combustible dust cloud atmospheres could exist under normal and/or abnormal conditions.

- Identify potential ignition sources that could exist under normal and/or abnormal conditions.

- Prevent the formation of explosive dust clouds in the plant and reduce the extent and duration of any clouds that may be formed.

- Take measures to eliminate/control ignition sources.

- Take measures to protect against the consequences of dust cloud explosions. Explosion protection measures include explosion relief venting, explosion suppression, explosion containment and explosion isolation. Where practical, one could consider the application of inert gas purging and/or padding to prevent the combustion process.

Laboratory Testing

To assess the possibility of an explosion in a facility and to select the most appropriate basis of safety, explosion characteristics of the dust(s) that are being handled/processed in the facility should be determined.

The explosion characteristics of powders normally fall within one of two groups, “likelihood of an explosion” and “consequences of an explosion”. Taken together these two characteristics determine the dust explosion risk of a material. These two groups of tests are discussed below.

Determining the “Likelihood of an Explosion”

The following tests provide information on the likelihood of a dust explosion.

Explosion Classification (Screening) Test (ASTM E1226,

Standard Test Method for Explosibility of Dust Clouds)

This test determines whether a dust cloud will explode when exposed to a sufficiently energetic ignition source. The test results in a powder being classified as either “explosible” or “non-explosible”. This test answers the question “Can this dust explode?”

Minimum Ignition Energy – MIE (ASTM E2019, Standard

Test Method for Minimum Ignition Energy of a Dust Cloud in Air)

The MIE test determines the lowest electric energy that is capable of igniting a dust cloud at its optimum ignitable concentration. The test is used primarily to assess the susceptibility of dust clouds to ignition by electrostatic discharges (sparks).

Minimum Ignition Temperature of a Dust Cloud – MIT Cloud (ASTM E1491, Standard Test Method for Minimum Auto-ignition Temperature of Dust Clouds)

This test determines the lowest temperature capable of igniting a dust dispersed in the form of a cloud. The MITcloud is an important factor in evaluating the ignition sensitivity of dusts to such ignition sources as heated environments, hot surfaces, electrical devices and friction sparks.

Minimum Ignition Temperature of a Dust Layer –

MIT Layer (ASTM E2021, Standard Test Method for Hot Surface Ignition Temperature of Dust Layers)

This test determines the lowest temperature capable of igniting a dust layer of standard thickness (5 to 12.7 mm). The MITlayer is used in evaluating the ignition sensitivity of powders to ignition by hot surfaces.

Self-Heating (J.A. Abbott (ed.) “Prevention of Fires and

Explosions in Dryers”, Institute of Chemical Engineers, 1990)

Ignition of bulk powders can occur by a process of self-heating when the temperature of the powder is raised to a level at which the heat liberated by the exothermic oxidation or decomposition reaction is sufficient to exceed the heat losses and to produce a “runaway” increase in temperature.

The minimum onset temperature for self-ignition of a powder depends mainly on the nature of the powder and on its dimensions. If these variables are predictable, a reliable assessment of the onset temperature for self-ignition and also the induction time to self-ignition can be made by appropriate small-scale laboratory tests:

- Bulk Powder Test: Simulates bulk powder in IBCs, bags, bottom of hoppers;

- Aerated Powder Test: Simulates fluidized bed processing;

- Powder Layer Test: Simulates powder deposits on dryer walls/surfaces and tray drying;

- Basket Test: Simulates large-scale storage or transport conditions.

Electrostatic Volume Resistivity (General Accordance with ASTM D257, Standard Test Methods for DC Resistance or Conductance of Insulating Materials)

Volume resistivity is the primary criterion for classifying powders as low, moderately or highly insulating. Insulating powders have a propensity to retain electrostatic charge and can produce hazardous electrostatic discharges.

Electrostatic Chargeability (General Accordance with ASTM D257,

Standard Test Methods for DC Resistance or Conductance

of Insulating Materials)

Electrostatic chargeability is a measure of the propensity of powder particles to become charged when flowing through conveyances or when handled in containers. This test provides data that can be used to develop appropriate material handling guidelines from an electrostatic hazards point of view.

Minimum Explosible Concentration – MEC (ASTM E1515, Standard Test Method for Minimum Explosible Concentration of Combustible Dusts)

The MEC test determines the lowest concentration of dust cloud in air that can give rise to flame propagation upon ignition. This test answers the question “How easily can an explosible dust cloud be formed?”

Limiting Oxygen (Oxidant) Concentration – LOC (ASTM E2931,

Standard Test Method for Limiting Oxygen (Oxidant) Concentration

of Combustible Dust Clouds)

The LOC test determines the minimum concentration of oxygen (displaced by an inert gas such as nitrogen or carbon dioxide) capable of supporting combustion. An atmosphere having an oxygen concentration below the LOC is not capable of supporting a dust cloud explosion. The LOC test is used to study explosion prevention or severity reduction involving the use of inert gases and to set oxygen concentration alarms or interlocks in inerted vessels.

Determining the “Consequences of an Explosion (Explosion Severity)”

Maximum Explosion Pressure, Maximum Rate of Pressure Rise,

Deflagration Index (Kst Value) (ASTM E1226, Standard Test Method

for Explosibility of Dust Clouds)

The maximum explosion pressure and maximum rate of pressure rise values are determined by using a 1m3 or 20-liter sphere test apparatus. The dust sample is dispersed within the sphere, ignited by chemical igniters, and the pressure and rate of pressure rise of the resulting explosion are measured. The cloud concentration is varied to determine the optimal dust concentration.

The maximum explosion pressure and maximum rate of pressure rise are measured, and the latter is used to calculate the deflagration index (Kst) value of the dust cloud. These data can be used for the purpose of designing dust explosion protection measures such as explosion relief venting, suppression and containment, and to classify a material’s explosion severity. This test answers the question “How bad is it if it happens?”

Approach to Process Safety Testing

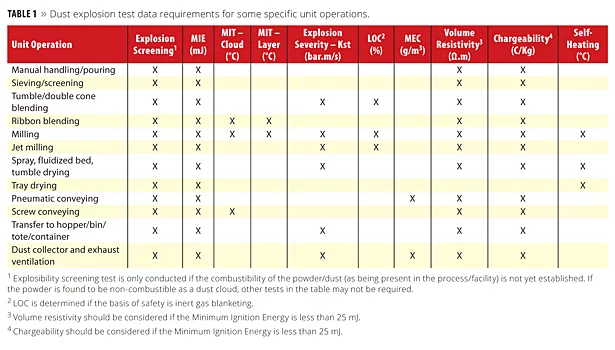

Table 1 specifies the type of data that might be required to assess dust explosion hazards associated with some common unit operations in the powder industry.

The Basis of Safety for Dust Cloud Explosion Hazards

Safety from dust cloud explosions includes taking measures to avoid an explosion (explosion prevention) or designing facilities and equipment so that in the event of an explosion, people and processes are protected (explosion protection). The selection of explosion prevention and/or protection measures is based on:

-

How much information is available on the sensitivity of the powder(s) to ignition and the resulting explosion severity;

- The nature of the processes and operations;

- The level of personnel’s knowledge and appreciation regarding the consequences of a dust explosion and adherence to the preventive measures (employee training);

- Environmental effects of a dust explosion; and

- Business interruption resulting from a dust explosion.

Explosion Prevention and Protection Measures

The risk of an explosion is minimized when one of the following measures is ensured:

- An explosive dust cloud is never allowed to form;

- The atmosphere is sufficiently depleted of oxidant (normally the oxygen in air) that it cannot support combustion;

- All ignition sources capable of igniting the dust cloud are removed; or

- People and facilities are protected against the consequences of an explosion by “protection measures” such as explosion containment, explosion suppression or explosion relief venting.

Secondary Explosions and Good Housekeeping

A technically well-designed plant is no guarantee of safety, if those who operate it do not understand the hazards involved, and the precautions designed to control them.

A majority of the most serious dust explosions over the years have not been caused by the primary explosion inside the plant, but from a secondary explosion within the building. A small initial event causes a pressure wave to propagate into the workplace, and dust deposits around the workroom are dispersed into a cloud, which subsequently ignites. This can happen in a series of connected rooms and result in horrific building collapses.

Secondary dust explosions are especially common in industries where traditionally little concern existed for the presence of dust outside the process equipment, as the material was not toxic and not particularly expensive.

Housekeeping activities must ensure that secondary fuel sources are not available. Of key importance is evaluation of dust release points and exhaust ventilation needs. It is much easier to replace a gasket, refit a manway, or install local dust aspiration systems, than to spend the time cleaning up the dust that has escaped.

Safeguard Reliability

All safeguards intended to prevent dust explosions must be recognized, understood and maintained by operating forces. Operators should be aware that signs of overheating, excessive vibration, or noises indicating mechanical malfunction or misalignment need prompt attention before a small smoldering clump of dust leads to a serious explosion. Likewise, protective safeguards such as explosion relief vents or abort gates must be appropriately designed and maintained with clear, safe discharges. A routine inspection and testing program should be created for safety critical explosion protections.

For more information, e-mail: safety-usa@chilworthglobal.com, or visit www.chilworth.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!