Specular Included or Specular Excluded: Which is Best?

Surface appearance can change your perception of color. Think of a glossy magazine. If the light is shining directly on the page, you may need to tilt the magazine and change the reflection angle to clearly see the colors. Likewise, a textured surface may appear to be a different color than a smooth surface of the same object.

Since spectrophotometers determine a color’s spectral values by shining light onto the surface and measuring the reflectance, choosing the right instrument and the proper measurement mode are crucial. These choices will determine what passes and what fails your tolerance, as well as how the results correlate to visual inspection.

Sphere spectrophotometers are the preferred choice for paints, coatings, plastics and textile applications because they can include or exclude the specular component of surface appearance. This ability is critical to being able to evaluate the color only OR the color and appearance of the object being measured.

How a Sphere Device Works

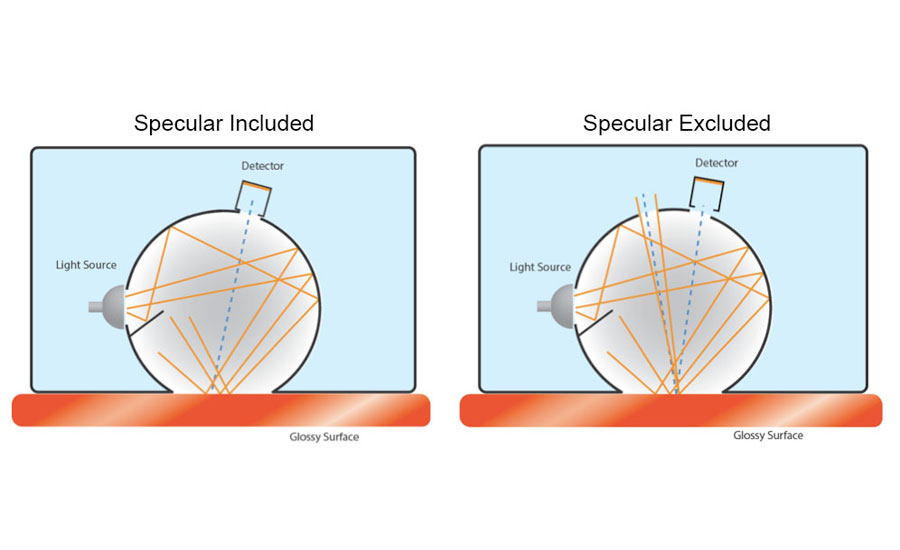

The interior of a sphere device is actually spherical in shape. The light source reflects off the white matte surface of the sphere’s interior, causing the light to scatter randomly in all directions. This process repeats itself thousands of times in a fraction of a second, creating a homogenous, diffuse illumination of the object. The detector then receives the reflected light at an 8-degree angle from the object’s surface to accurately measure the color.

There are two ports in a sphere instrument, the Sample Viewing Port and the Specular Port. The Viewing Port contains the receiver and the light sensitive detectors that quantify the light reflecting from the sample’s surface. The Specular Port can either be open or closed to control the type of measurement.

If the port is open, the device will take a Specular Excluded reading. If the port is closed, the device will take a Specular Included reading.

Specular Excluded INCLUDES Surface Appearance

Measuring Specular Excluded (SPEX) – aka Specular Component Excluded (SCE) – is similar to how your eye perceives color. The surface characteristics become part of the color you see. In other words, a glossy surface will typically measure darker than a matte surface of the same color – just the way you see it.

When the Specular Port is open, instead of reflecting back onto the surface of the sample, light from that portion of the sphere wall is directed into a black trap and lost from the measurement. The glossier the surface, the less percentage of color will return to the instrument's optical receiver. If the surface of the sample is a perfect mirror (100% gloss), the instrument will read the color as perfect black, no matter the “true” color.

Specular Included EXCLUDES Surface Appearance

Measuring Specular Included (SPIN) – aka Specular Component Included (SCI) will capture true color data from the sample, regardless of surface appearance. Similar to the way your eye would see the magazine picture without the gloss reflection, measuring Specular Included negates the effect of surface appearance to measure only color.

If the Specular Port is closed, the black trap is replaced with a white tile or plate, which is included in the process of lighting the sample. If the sample is glossy, this portion of the sphere will send the gloss signal directly into the viewing port.

Lighting the surface uniformly from all possible directions creates the ideal measurement environment for samples that are either highly polished, like mirrors and metallic packaging, or very textured, such as carpeting and roofing tiles.

Which is Best for Measuring “True” Color?

In these samples you see two swatches, one matte and the other glossy. Although the matte sample appears to be lighter, they are both the same color. Which measurement mode – Specular Included or Specular Excluded – should you use for these samples?

For formulation, the industry-accepted answer is Specular Included. If you configure a sphere instrument to collect all reflected light – specular as well as diffuse – then it makes little or no difference if the sample is mirror like or matte in appearance. The recipe controls the final color, and these swatches will measure as the same color black or gray.

While this makes sense in the lab, the goal is slightly different during quality assurance. If a manufacturer uses this black color to coat a metal cabinet, but chooses a glossy finish for the side panels and matte for the drawers, will the final product be appealing to the buyer? Probably not. But if the QA department measures these parts Specular Included, the two blacks will measure as the same color, and this cabinet will be shipped with side panels and drawers that do not match. In this case, measuring Specular Excluded is preferred because it captures color the way the human eye sees it.

To Learn More

Our Color Theory: Understanding the Numbers of Color e-learning course covers this topic and much more. From the physics of color to lighting, spectrophotometers and color data, this module-based course delivers an in-depth understanding of color.