The Effective Use of Interference and Polychromatic Colorants

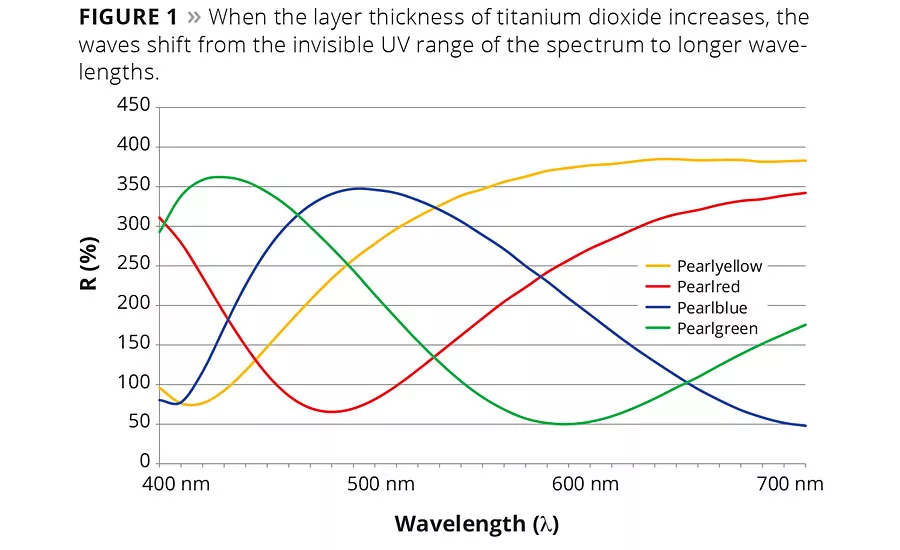

Figure 1

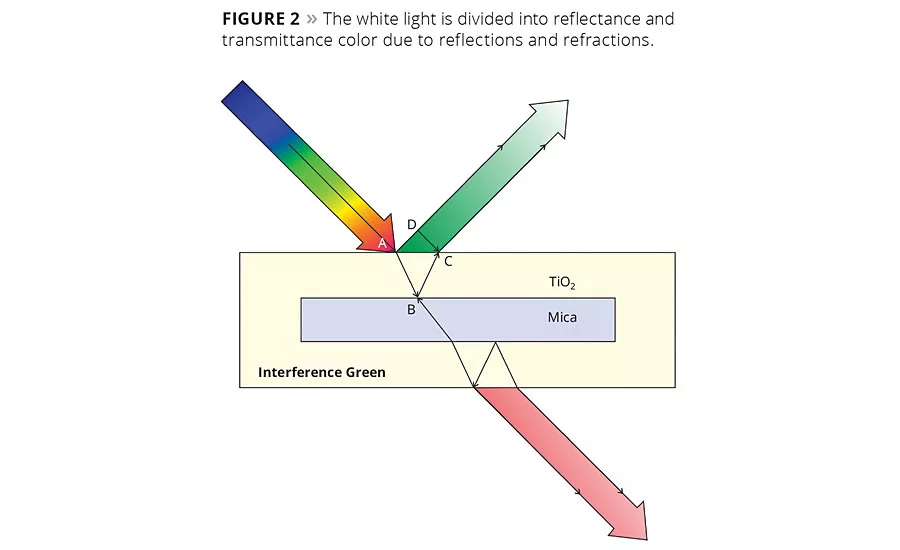

Figure 2

Figure 3

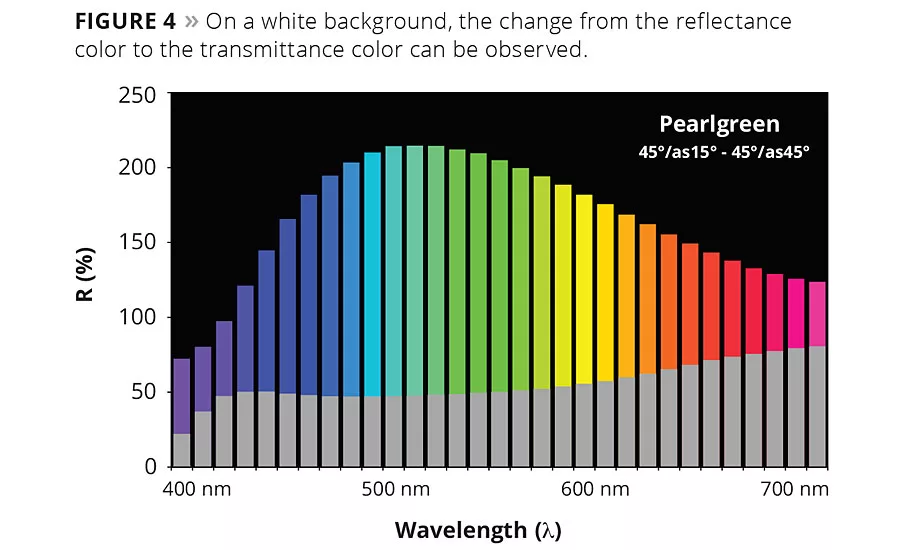

Figure 4

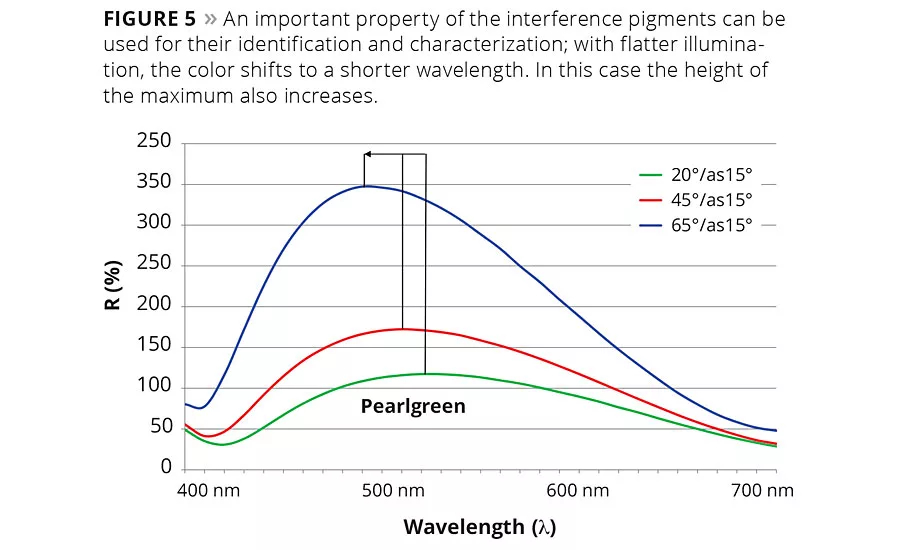

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

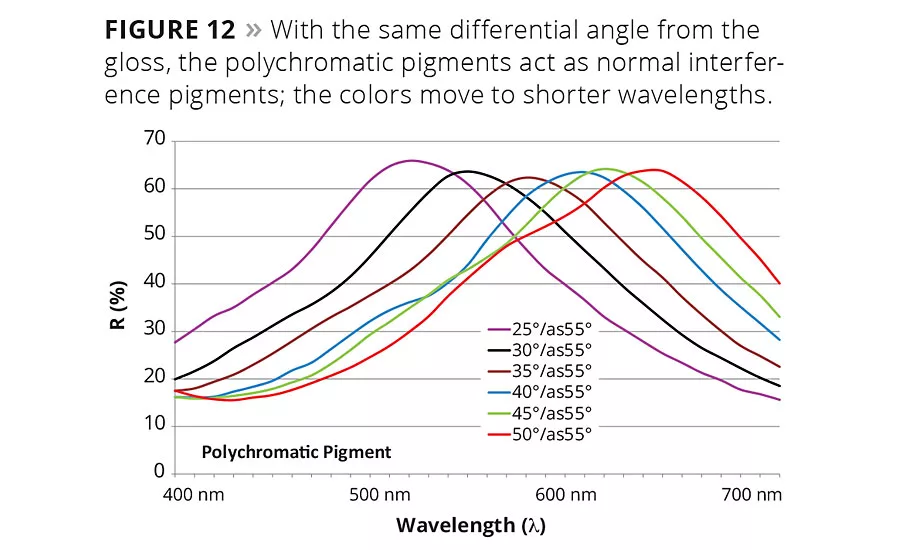

Figure 12

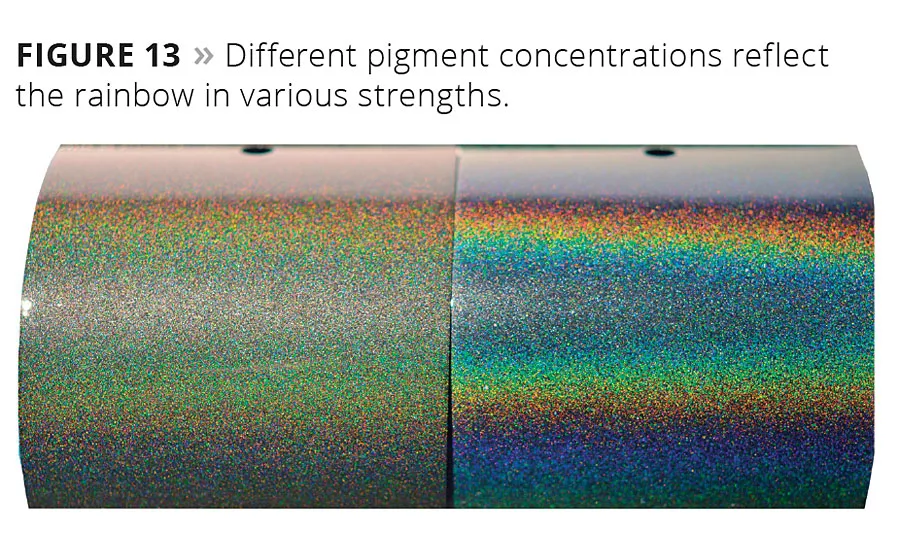

Figure 13

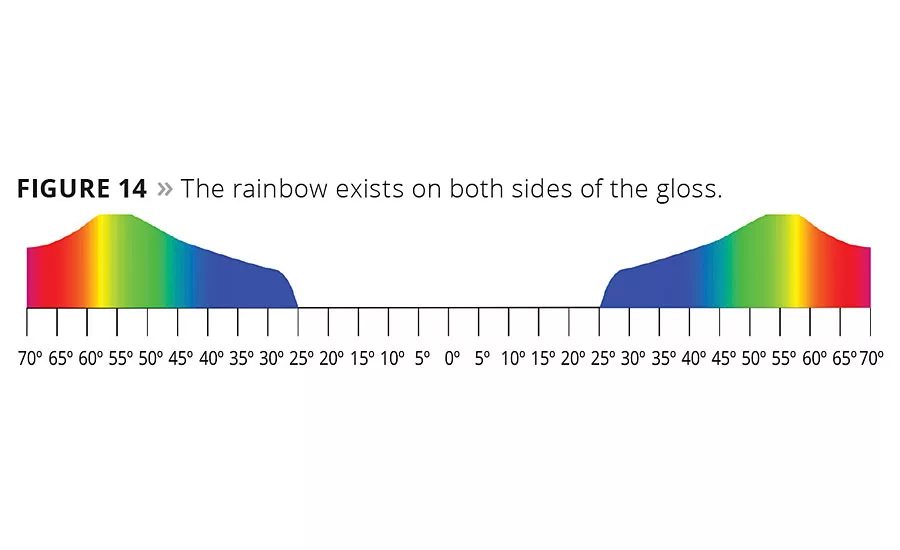

Figure 14

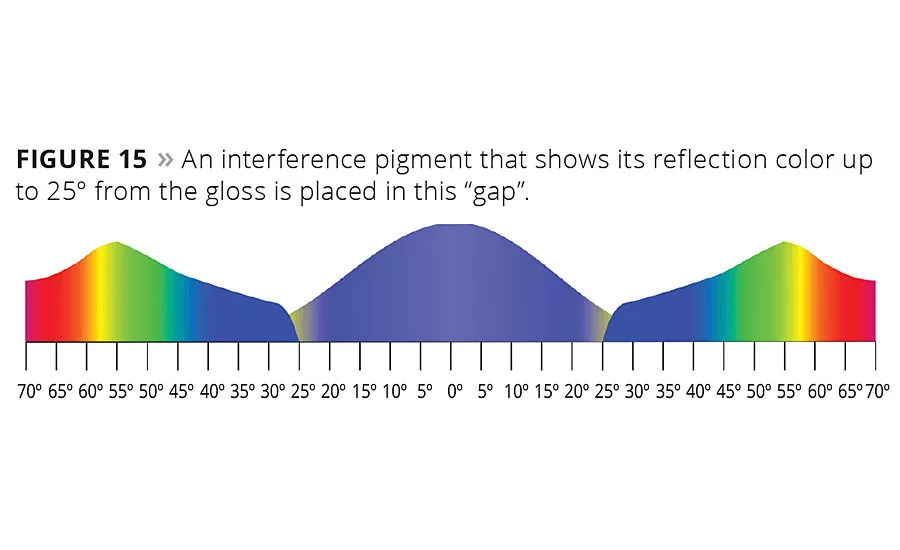

Figure 15

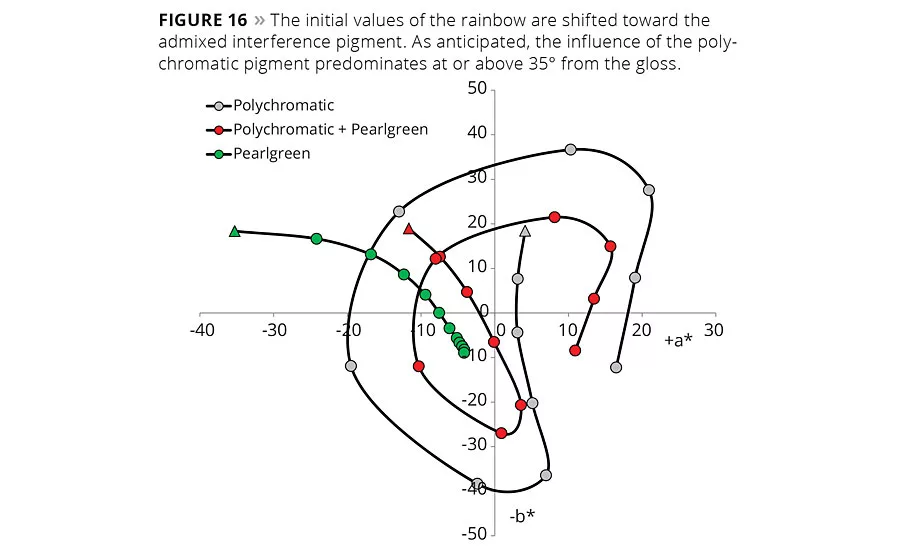

Figure 16

Figure 17

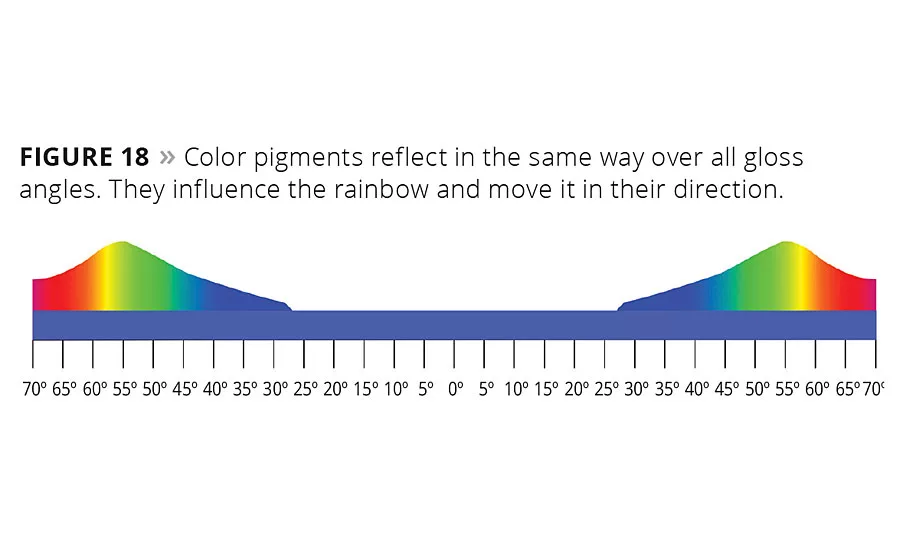

Figure 18

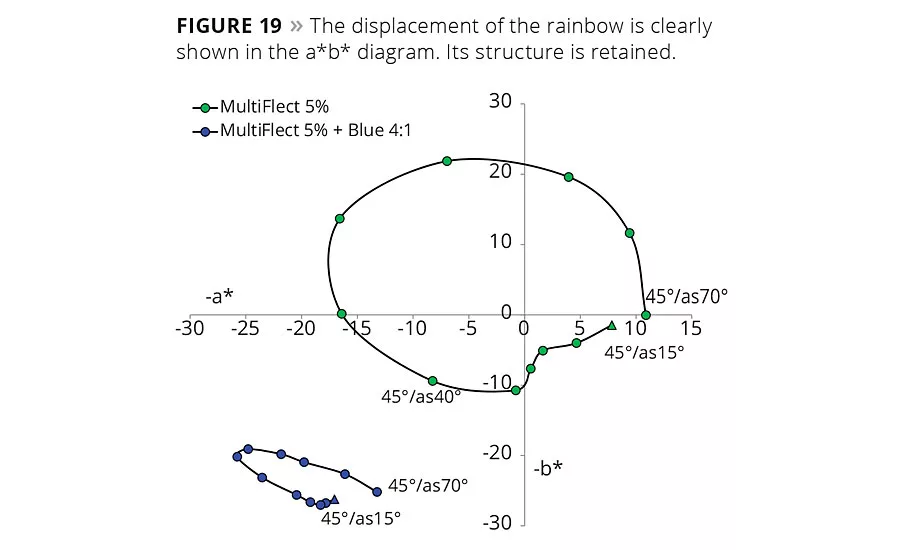

Figure 19

Interference pigments are among the most optically sophisticated pigments. Unlike colored pigments that absorb some of the incident light and metallic pigments that reflect the incident light, interference pigments involve superimposed light waves that are shifted together due to reflections and refractions, thereby causing strengthening or weakening of the resulting light wave. Various factors such as the layout of the pigment, its application and the lighting make for optimum conditions.

Pigments manufactured with wet chemistry generally have a carrier platelet of natural mica, silicon dioxide or aluminum oxide. High refractive metal oxides such as titanium dioxide or iron oxide are applied to this carrier platelet. Due to different layer thicknesses of titanium dioxide, these pigments change their color from white, yellow, red or blue to green. This unusual color shift results from the fact that the maximums - and also the minimums - move to longer wavelengths. For yellow, the minimum shifts from the UV range into the visible region, whereby white turns into a yellow. This minimum shifts further into the longer wavelengths with increasing layer thickness of the titanium dioxide, which results in a red. The maxima following the minimum in the UV range migrates into the visible range, while the maximum in the long wavelength range travels into the invisible infrared range. With higher layer thickness the blue maximum shifts into the green range. Such pigment group color sequences are thus chemically identical, differing only in the layer thickness (Figure 1).

Interference pigments have been used in car paints since the mid-80s. Since that time, there has been increasing interest in quantifying their colors and effects. They are applied in so-called basecoats, which are then sealed with clear coat. These basecoats have a layer thickness of 10-15 µm; the interference pigments are in the range of 5-100 µm long and about 0.05 µm thick. Due to this size, the pigments can only be situated as platelets in the paint. This orientation is supported by additives during the drying of the basecoat. The theoretical calculation of the orientation of the pigments on the basis of measuring angles must therefore be questioned. Patterns viewed in the electron microscope show a relatively flat orientation; in the light microscope, the change in the illumination angle shows that the observed colors almost always arise from the same pigments and not from differently oriented pigments.

Most interference pigments are transparent, which is why the color of the background or environment also plays a role. Since the incident light is divided into the reflectance color and complementary transmittance color, the change can be observed well on a white background. With measurements close to the gloss, the reflectance color is detected and the transmittance color is further away from the gloss. This transmittance color is produced on the opposite side of the pigment, reflected by the white substrate. If angular differences are measured from the gloss angle with an illumination angle of 45°, the reflectance color in the range can be detected up to about 20°. Between 20° and 30° from the gloss angle there is a so-called transition range. With large difference angles, the complementary transmittance color that is reflected from the white background is measured. A black background absorbs the transmittance color. Colored backgrounds as well as admixtures of colored pigments show similar patterns (Figures 2-4).

Properties Applied to Interference Pigments

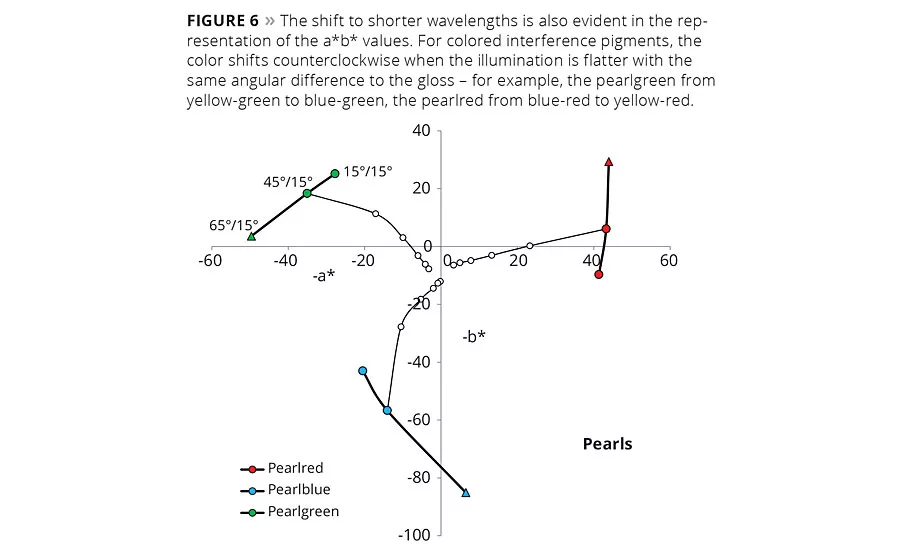

The laws of optics describe three properties that can be applied to interference pigments. On the one hand, the reflection maximum shifts to shorter wavelengths when the illumination is flatter. This is a crucial property for the characterization and identification of interference pigments. This optical property can be technically measured in that the illumination angle is changed from a steep angle to a flatter one, whereby the differential angle remains constant for each respective gloss angle. This results in a typical interference line for the respective pigment. An aspecular angle of 15° has proved particularly useful here. Measurements at aspecular angles closer to the gloss often run the risk of incorrect measurements, especially when it comes to samples with a clear coat (Figures 5 and 6).

The second property is demonstrated in the course of the reflectance curves. They not only shift to a shorter wavelength, but their maxima rise considerably with flatter irradiation. As a result of this property, the interference line in the a*b* diagram always runs in a counter-clockwise direction with flatter lighting. Thus, the color of a red interference pigment shifts from bluish red to yellowish red, and a green shifts from yellowish green to bluish (Figure 6).

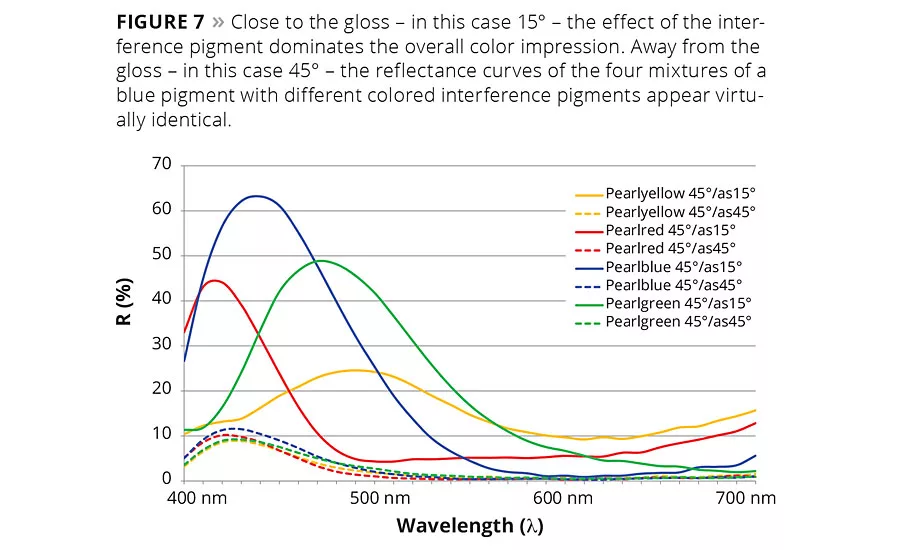

The third property relates to the measurements at constant illumination. Commonly a constant illumination angle of 45° is recorded, but other angles such as 65° are possible. Since all interference pigments close to the gloss show their reflectance color, which can also be measured, it can also be observed and measured even in unusual mixtures with colored pigments. Thus the blue reflectance color is retained even if the corresponding pigment is mixed with a green or red color pigment. Basically, an effect arises from the fact that the color and/or brightness changes depending on the geometry. And with interference pigments the reflectance color is always detected close to the gloss. The overall color appearance of a pigment mixture is affected differently by the pigments it contains. This applies to the colored pigments, aluminum pigments and interference pigments. Colored pigments affect the overall color impression across all geometries, aluminum pigments close to the gloss and interference pigments mainly to about 25° from the gloss. Thus the color of the interference pigment is affected by the colored pigments that also reflect close to the gloss (Figure 7).

But measurements at a constant illumination angle and varied angular differences to each gloss angle are not limited to an illumination angle of 45°. In principle, the 45° illumination has emerged as the most suitable for characterization. The combination of these measurements results in the so-called “aspecular line,” and the combination of the measured values at a constant differential angle is referred to as the “interference line.” Again, the indication of the aspecular angle is necessary because there may be multiple connection lines. At an aspecular angle equal to or greater than 30°, the transmission colors are measured with transparent interference pigments on a white background.

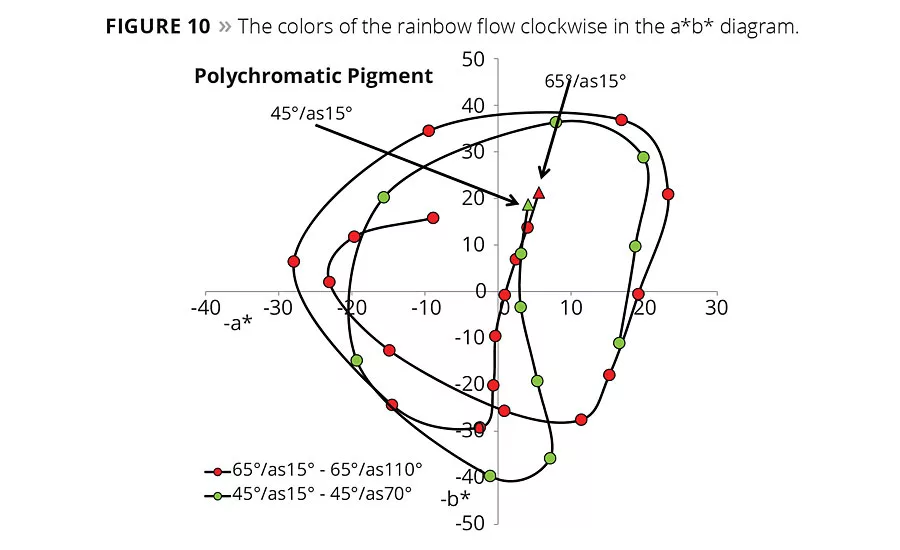

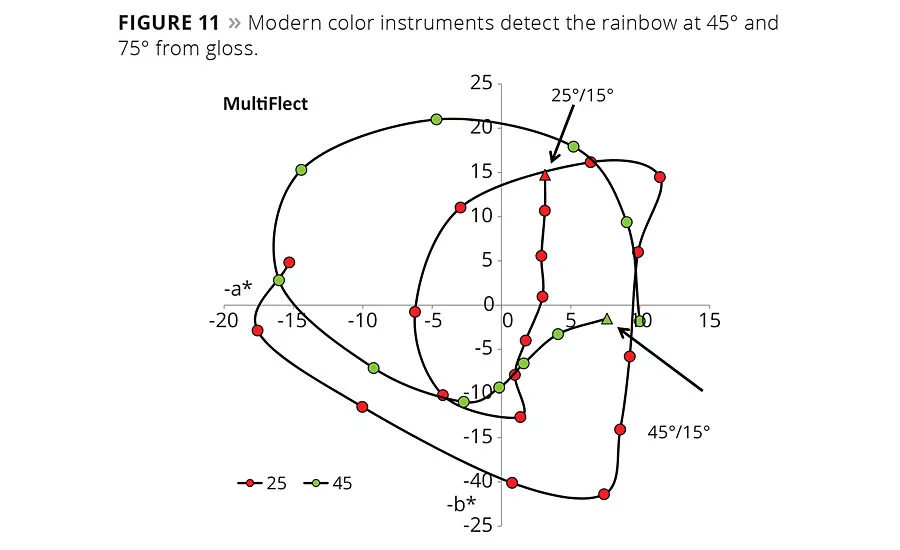

In addition to the known interference pigments, which are prepared by wet chemistry or in a high vacuum, there are special types of interference pigments. Their optical response corresponds to reflections on the grid. The incident light is known to be spectrally fragmented, from blue-violet over blue, green, yellow to red. Unlike “normal” interference pigments, which show a color gradient depending on the angle of illumination, a complete rainbow is always evident in the polychromatic pigments (Figure 8). Its colors can be measured individually -the eye has a greater observation and detection range than a measuring instrument and sees a complete rainbow. The range of the rainbow lies in an angular range of 20 to 30 degrees depending on the angle of illumination: with flat 65° illumination the rainbow starts at about 45° and extends to about 75° from the gloss angle. With steeper illumination at 45°, the range shifts from 35° to 65°. These are the limits for the colors of the 1st order. The colors of the 2nd order follow in this range; are measurable, but barely visible.

From the reflectance curves it is clear that the reflections and their maxima shift from the UV range into the visible range with increasing aspecular angle to the gloss angle. With a further increasing aspecular angle they leave the visible spectral range in the infrared region, while maxima of the 2nd order move from the UV into the visible range (Figures 9-11).

The interference laws - the shift of the reflections to shorter wavelengths with flatter illumination - also apply to these pigments. Presuming aspecular geometry - for example, 55° - and if the reflections of different illumination angles have this constant differential angle, the shift of the maxima to shorter wavelengths with flatter angles of illumination can be clearly seen. Thus, in these pigments, the optical reflection laws apply on the grid and the interference (Figure 12).

Combinations with Colored Pigments and Interference Pigments

Interference pigments have typical reflection colors with a small or large color gradient. They are found in many car colors in combination with color and aluminum pigments. In order to create a blue color effect, for example, a white interference pigment can be mixed with a blue color pigment. Instead of the white interference pigment a blue or green may also be used. The combination possibilities here are almost infinite.

In the case of polychromatic pigments, the combinations are made somewhat differently; admixtures of color and aluminum pigments influence the polychromatic rainbow effect.

Polychromatic pigments are inherently silver-white to silver-gray from their base color. The rainbow effect occurs most clearly with these neutral pigments. Admixtures of color pigments suppress the rainbow partially or even completely, so that in principle some preliminary considerations are necessary:

- The complete rainbow exists only in polychromatic pigments or with minimal admixtures. To obtain the rainbow, the combination possibilities are very limited. Admixtures of black are ideal, because in this case the colors of the rainbow are not affected. And because of the greater contrast, the rainbow effect is more intense. When such pigments are used, the rainbow is always shown; there are no pigments that show only a half or a quarter of the rainbow. In this case the effect must be controlled with admixtures with other pigments (Figure 13).

- The rainbow starts at about 35°-45° aspecular; interference pigments show - depending on the type - their reflection color up to about 25° aspecular. In this respect, two color ranges can be used by mixing both types of pigment. Looking at a spray-out of a polychromatic pigment from above, one can detect the “gap” between the two rainbows on either side of the angle of observation. An interference pigment can be incorporated that fills this “gap,” so to speak. Such mixtures can be created in various ways, whereby the selected color of the interference pigment may also affect the rainbow (Figures 14-17).

- Admixtures of color pigments influence the color impression over the entire illumination and observation range. Depending on the color of the color pigment, the rainbow is affected and is no longer recognizable in its entirety. Like colors of the interference pigments, the rainbow appears intense only in a narrow angular range. Despite their comparable lower intensity close to the gloss, color pigments produce a stronger overall color impression. As such, they often have a strong influence on the rainbow, which can only demonstrate a strong presence in combination with dark color pigments (Figures 18-19).

Examples of mixtures of MultiFlect with blue color pigment and blue interference pigment show the respective influences in the geometrics areas. Near the gloss at 15° aspecular – in this case with an illumination of 45° - the MultiFlect pigment reflects with a slight valley in the green range; away from the gloss angle - in this case at 50° aspecular - the green of the rainbow can be seen.

By adding a blue pigment, the as45° reflectance curve shifts to higher values, above all in the blue spectral range; close to the gloss the as15° reflectance curve is slightly increased in the blue and red range. The differences in mixtures with blue interference pigment are even more distinct. Their reflections close to the gloss affect the resulting reflectance curve with a strong maximum at 15° from the gloss. The reflections of this pigment shift, so to speak, between the rainbow reflections of the MultiFlect pigment. This optical behavior can also be observed visually; left and right of the gloss we can see the rainbows and the blue interference color between them. Interference pigments in other colors provide the same results, whereby their reflection color provides a more or less strong contrast to the rainbow.

Plotting the a*b* values shows a shift of the rainbow circle into the blue area with the addition of a blue color pigment. The addition of a blue interference pigment causes the unfolding of this circle in the blue region. Experiments with different color pigments and interference pigments show similar color reactions.

Conclusion

As with all effect pigments, the use of polychromatic pigments requires an intensive examination of illumination and observation geometries, if useful and interesting color creations are to be produced. Although these pigments “only” show a rainbow, admixing interference pigments in particular can create effects that exploit the optical properties of both types of pigment. In addition, color pigments can be used that can have a crucial effect on the overall color across all geometries. Starting from the polychromatic pigment, different approaches for color creations can be implemented. Certainly the use of this type of pigment is particularly limited in the automotive sector, but it can be used for attractive concepts in special series. This requires detailed knowledge of the geometric constraints of the colors. The difficulty in developing this knowledge stems from the fact that the geometries of the rainbow are only partially recorded by the measuring geometries of most spectrophotometers.

This article was previously published in the April 2016 issue of the European Coatings Journal, published by Vincentz Network.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!