Overcoming Performance Challenges with Waterborne DTM Coatings

Figure 1

Figure 2

Direct-to-metal (DTM) coatings protect metal substrates from corrosion and serve a dual purpose as a topcoat. Waterborne DTM coatings are suitable for light-duty applications such as interior spaces where condensation may occur or exterior environments with low levels of pollution, and are used as coatings for pipes, tanks, handrails, steel doors, rail cars, etc. When compared with multilayer coatings (primer layer followed by a topcoat layer), there are cost and time advantages in choosing DTM coatings. These coatings are intended to be applied after minimal surface preparation with only one application step, and are designed to provide corrosion protection without the need for active pigments. Waterborne acrylic DTM coatings can provide a high-gloss finish (>80 on a 60° meter) with good appearance and protect the metal substrate from corrosion.

Waterborne coatings provide advantages over solventborne coatings because they are better for worker health and safety, with less impact on the environment. Waterborne coatings are easy to clean, can be thinned with water and use solvents that are lower in odor, toxicity and flammability. Lower-VOC acrylic coatings also dry faster, which allows for faster recoating times. One of the challenges of waterborne coatings in general, however, is that application conditions can affect the appearance and performance of the coatings. Low temperatures and extreme humidity (high or low) must be avoided for optimal application appearance and film formation.

Formulating waterborne coatings that are intended to protect metal comes with a unique set of challenges. This article discusses some of the things I have discovered in formulating for waterborne acrylic coatings for corrosion protection, and might serve as guidelines for formulators who want to improve the performance of waterborne DTM coatings.

Formulation

The corrosion protection provided by waterborne acrylic coatings is highly dependent on both the resin and the formulation of the coating. Attempting to drop in, or directly replace resins in waterborne formulations does not result in optimum performance. The appropriate solvents, additives and pigments must be chosen to work well with the resin to optimize the performance of the coating.

Film formation in waterborne latex binder systems is a complex process that relies on co-solvents and sometimes a low-VOC coalescent to lower the minimum film formation temperature of the latex polymer enough to allow the particles to deform and coalesce. Polymer chains at the surface of the particles then diffuse across particle boundaries and develop a continuous film. As binders in protective coatings often act as a barrier, the solvent type and level must be optimized with the binder and the formulation to maximize resistance to water and salt. The choice of solvent can have a dramatic effect on the early water resistance of coating formulations, and salt spray results can be improved by ensuring sufficient co-solvent level. Another consideration is the type of water that is used in formulations of metal protective coatings. Ideally, de-ionized water should be used, as the additional ions found in tap water have a negative effect on corrosion resistance.

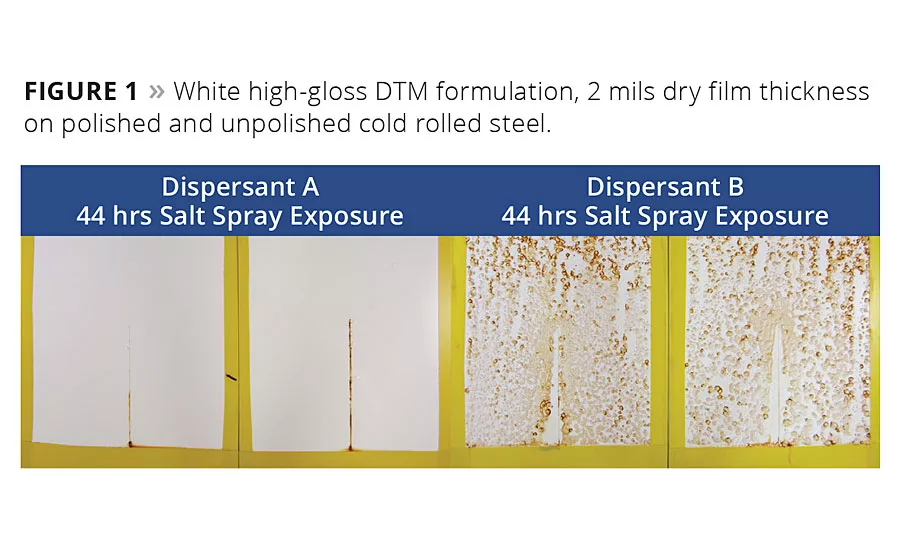

A very good dispersion of pigments is necessary to avoid agglomeration and resulting film defects that allow water penetration into the film. Dispersant choice that is compatible with the binder is critical for corrosion resistance. Even a dispersant optimized for standard properties like gloss and adhesion can have a negative effect on corrosion resistance. Figure 1 shows the same formulation with two different dispersants after 44 hrs of salt spray exposure. The difference in performance is dramatic, with the dispersant on the left showing no failure in the field or at the scribe and the dispersant on the right showing complete failure in field rusting after only 44 hrs.

The choice of pigment can also have a dramatic effect on the corrosion resistance of DTM coatings. These high-gloss coatings generally do not contain active pigments, but the type of titanium dioxide (such as the kind with an organic treatment to enhance dispersibility) can also negatively affect corrosion and water resistance of the film. Figure 2 shows the same formulation with two different grades of TiO2 pigment after 276 hrs of salt spray exposure.

Since coatings come in many colors other than white, colorants are also used to tint DTM coatings. These pre-dispersed pigments also contain surfactant-type dispersants that can adversely affect the corrosion and water resistance. When using colorants it is best to choose those that are recommended for industrial coatings as opposed to those optimized for architectural coatings.

Additives such as defoamers, wetting agents and thickeners are necessary components of any coating formulation; however, they can also negatively impact corrosion and water resistance properties. The complete elimination of foam in a coating is necessary to ensure good, continuous film formation. Other surfactants can be used to improve pigment wetting, flow and leveling in the final film. In general, the more hydrophobic the better, but the optimal choice will be system-dependent. Associative nonionic thickeners like HEUR and HMPE types are generally preferred for better film formation and to minimize the effect on corrosion resistance when compared with clay or alkali-swellable thickeners.

One additive that must be included in all waterborne DTM coatings is a flash rust inhibitor to prevent flash rust of the metal during the drying process. This can be as simple as sodium nitrite, but often commercially available flash rust inhibitors will contain additional ingredients that improve effectiveness and also provide an improvement in corrosion resistance. The type and level of flash rust inhibitor will need to be optimized for the coating to ensure that flash rust is prevented even under extreme drying conditions such as at very high relative humidity (80-95%).

Application

Industrial maintenance coatings can be dipped, sprayed, brushed or rolled, and the viscosity of the coating must be adjusted for each type of application. When developing and testing binders for these types of coatings, films are prepared by drawdown as well as by spraying. This is because the film formation is different depending on the method of application. For films that are sprayed using conventional air atomized spray (standard or HVLP, high-volume, low-pressure type spray gun), the viscosity of the coating must be reduced with DI water to about 70 KU. Because of the larger volumes of paint required for industrial equipment, it is difficult to test airless spray application on a laboratory scale.

The wet film thickness of the coating can be approximated by testing with a wet film thickness gauge. The dry film thickness is the wet film thickness multiplied by the volume solids of the coating. The target dry film thickness (DFT) for a DTM topcoat is approximately 2 mils (50 microns); however, some coatings applications require as low as 0.5 mils or as much as 8 mils DFT. One advantage to preparing test panels over metal substrates is the ability to measure the dry film thickness accurately in a nondestructive method using a digital film thickness gauge. These instruments use the principle of electromagnetic induction for nonmagnetic coatings on magnetic substrates such as steel, and the eddy current principle for nonconductive coatings on nonferrous metal substrates.

Films for testing can also be prepared by drawdown using bars or rods. Bars come in different designs, such as Bird bars, doctor blades or latex film casters, and either the gap or the wet film thickness (approximately 50% of the gap) will be specified, depending on the type of bar. The actual wet film thickness will depend on the shape of the applicator, the viscosity, surface tension and wetting properties of the coating, as well as the speed of application. Rods are either wire-wound or wireless, but in either case the coating flows through the grooves and the wet film thickness is designated by the wire size of the rod. Higher coating viscosities (80-100 KU) lead to more consistent films when drawn down with a bar. With a rod there must be sufficient flow to level the film or defects may form due to thinner coating where the wire contacts the panel.

After application, films are allowed to dry at room temperature. One of the challenges of waterborne coatings is the necessity to avoid extreme conditions in temperature and humidity for application or drying that can result in poor film formation that affects performance. In the laboratory, drying is completed in standard conditions: 23 °C, 50% relative humidity. Corrosion testing is started after seven days of ambient cure. With these DTM topcoat formulations at 2 mils DFT, seven day testing has been successfully accelerated by one day of ambient cure followed by one hour in a 50 °C oven. Prior to testing for water resistance or corrosion, the back and edges of the panels must be covered with a more durable coating or adhesive tape such as vinyl floor marking tape.

Testing

Direct-to-metal coatings are tested on a variety of metal substrates, but primarily on steel for corrosion resistance. Cold rolled steel panels that are cleaned and unpolished can be purchased for testing so that a consistent, uniform substrate can be used to evaluate coatings and minimize variation of the steel. Other potential types of steel that may be used are polished cold rolled steel, sandblasted hot rolled steel and cold rolled steel with an iron phosphate treatment, with or without a sealer (chrome or nonchrome).

Corrosion resistance of the coating is most often evaluated using a continuous salt spray (salt fog) chamber according to ASTM B117. This test uses 5% sodium chloride salt fog at a constant temperature of 35 °C. Although this is the most common and most widely accepted corrosion test, it does not necessarily correlate well with field performance. Panels are taped and scribed prior to testing. The creep at the scribe is rated according to ASTM D1654, and the rust in the field is rated according to ASTM D610.

Other corrosion tests that have better correlation to field performance are prohesion or cyclic salt spray (fog) testing according to ASTM G85-A5, or testing that combines prohesion and UV exposure, ASTM D5894. The prohesion test uses a dilute salt solution (0.35% ammonium sulfate + 0.05% sodium chloride) and cycles between one hr of salt fog at 25 °C and 1 hr of drying at 35°C. The combined testing is 1 week (168 hrs) of QUV-A testing (4 hrs UVA (340 nm)/4 hrs condensation) followed by 1 week of prohesion testing for a total of 1008 hrs (6 weeks, three cycles of each).

In addition to corrosion testing, wet and dry adhesion over a variety of metal substrates is evaluated according to ASTM D3359 at various intervals of drying such as 1 day, 3 days and 7 days. One method to evaluate wet adhesion is to scribe the film, cover the scribe with a piece of filter paper, saturate the filter with water and cover with a watch glass. After 60 min the area is blotted dry, tape is applied and pulled to evaluate adhesion. Water resistance can be evaluated a number of different ways including immersion in water and using a humidity chamber according to ASTM D2257, a continuous DI water fog at 100% relative humidity and 35 °C. Adhesion after water exposure is also evaluated.

Conclusions

Waterborne direct-to-metal coatings are increasingly finding application in industrial maintenance coatings. The corrosion protection provided by these high-gloss coatings has improved with advances in binder technology; however, when formulating a waterborne DTM every component of the formula contributes to the corrosion performance. Binders have been developed that have very good corrosion resistance but must also be formulated for good film formation and with careful selection of additives and pigments. Replacing a resin in an existing formula may not result in optimum performance. Starting-point formulations and technical data sheets provided by the resin supplier are guidelines for appropriate raw material selections.

For more information, Email lori.boggs@basf.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!