A New Tin-Free Silicone Gum Dispersion

for Use as a High Slip Agent for Coatings and Leather

The market, especially the European market, has developed a tin sensitivity. In this article we report on the development of a tin-free aqueous silicone gum dispersion from early tin-based compositions. This class of additive has historically been very difficult to manufacture, especially without the tin condensation catalysts. These new compositions will be compared in several formulations against each other and the industry standard for their ability to reduce coefficient of friction (COF), and provide slip and mar resistance while maintaining coating properties.

These high-molecular-weight (MW) silicone dispersions are used in many coatings and leather treatment formulations to provide slip, and mar and stain resistance. The standard process, which includes catalysis with tin, is under strong regulatory pressure, especially in the EU, due to toxicity concerns of the residual tin compounds.

Variations in formulation and processing the high-molecular-weight silicone oil and silicone gum dispersions are evaluated against the commercially available product with the goal of achieving comparable or improved slip, dispersibility and stability.

Experimental

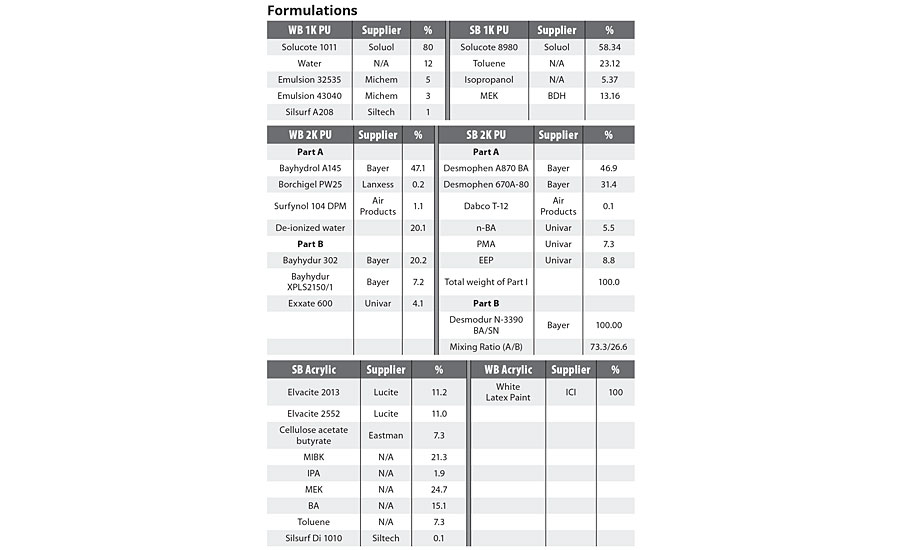

The experimental additives were screened at 0.5% or 1.25% in a variety of waterborne (WB) and solventborne (SB) formulations. The details of these formulations are shown in the formulations section at the end of the article. In examples 35A, 45A and 45B, the formulations labeled SB and WB HG enamels are proprietary formulations.

Two control experiments were conducted in each case. The first is a comparable use level of the commercially available competitive product labeled COMP, and the second is no additive, labeled CONTROL.

Variations in the silicone dispersions are shown as 40A-F (Tables 2 and 3), which are variations on one tin-catalyzed base formulation that uses a high-MW silicone. Formulations 40G-J (Table 4) are variations on a second base formulation that differs in the inclusion of higher MW silicone.

Finally, the best results are obtained with 35A and 45A-B (Table 5), which are dispersions of a silicone gum with minor changes in the three formulations.

Test Panel Preparation

For the solvent-based acrylic clear coating, acrylic latex paint and 2K waterborne polyurethane clear coating, all tested panels were prepared by drawing down approximate 1 mL coating liquid on a 4” X 6.5” Leneta paper with wire-wound rod #30. The wet films were allowed to dry at ambient conditions for at least 4 days, except where otherwise noted.

For 1K waterborne polyurethane coating, wire-wound rod #5 was used to cast about 0.5 mil wet liquid on Leneta paper. The wet film prepared with 2K waterborne polyurethane clear coating was dried in a 110 °C oven for 30 min or in an 80 °C oven for 60 min.

Mar Resistance Test

Mar resistance was measured using a Sutherland 2000 Ink Rub Tester. We used the Dry Rub method with the following settings: 100 rubs and 84 rpm stroke speed. Rubbings were done using a 4 lb test block that was attached with a 2” x 4” nylon scrubbing pad. The panels were rated based on percentage change in gloss reading before and after the rubbing test. Rating 10 is the best; 0 is the worst.

In the case of samples 35A, 45A and 45B, shown in Table 5, 300 rubs were used to increase the stress of the test.

Coefficient of Friction

Slip or coefficient of friction (COF) was measured with Chem-Instruments Coefficient of Friction - 500. (Test speed: 15 cm/min; travel length: 15 cm; sled weight: 200 grams and sled surface that was covered with ASTM-specified rubber). Static coefficient of friction was directly obtained from the equipment, representing the ratio of the horizontal component of the force (required to overcome the initial friction) to the vertical component of the object weight (200 grams). Kinetic coefficient of friction was also directly obtained from the equipment, representing the ratio of the horizontal component of the force (required to cause the object to slide at a constant velocity) to the vertical component of the object weight (200 grams). The greater the value, the higher the friction is for the substrate.

Gloss

Gloss was measured with a BYK-Gardner 60 micro-glossmeter before and after mar resistance test. The value was directly recorded from the micro-glossmeter.

Results

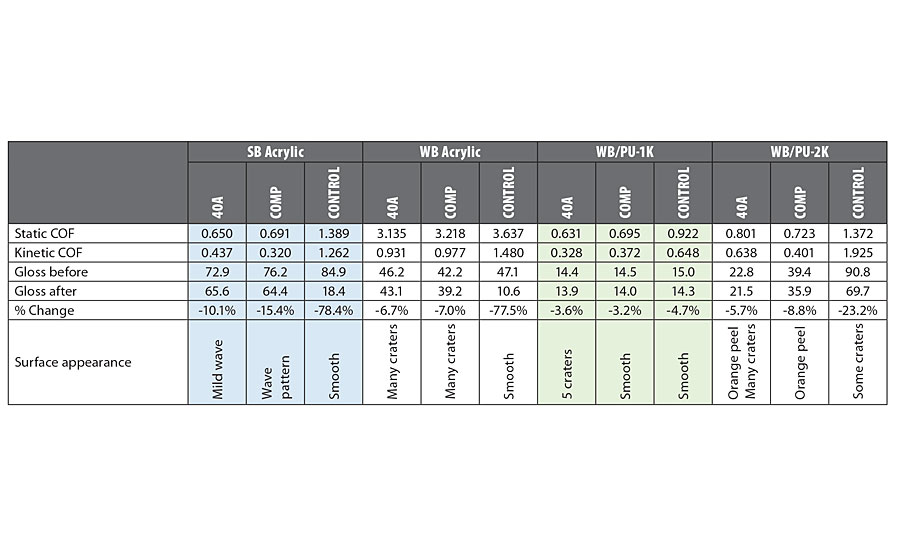

With the initial formulation (Table 1), we find the performance of our first sample, labeled 40A, to be as good as or better than COMP in terms of gloss retention and COF reduction. However, compatibility in WB formulations is not nearly as good, as evidenced by the surface appearance. Further work focused on improving the dispersibility with particle size and stabilizer packages.

Table 1 » Sample 40A.

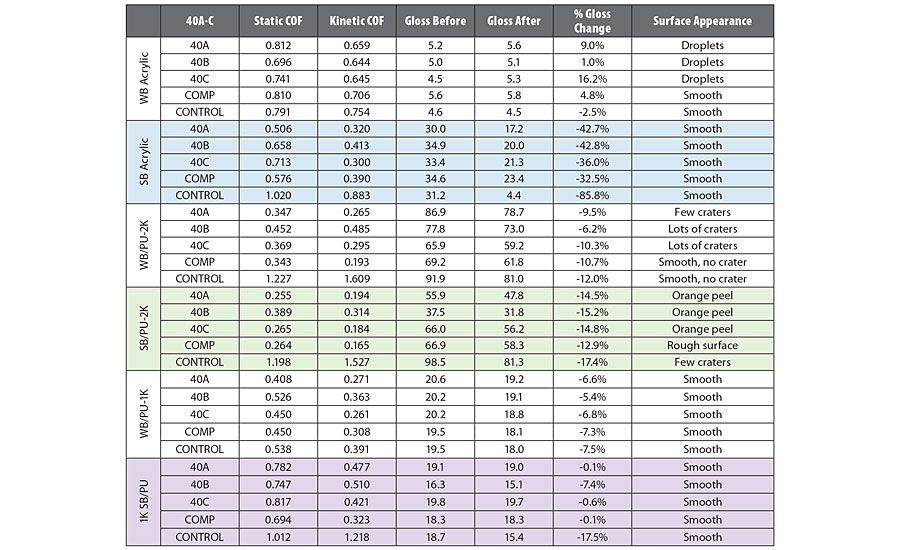

In the first variations, shown in Table 2, we see a similar result where physical properties are acceptable for 40A and 40C, but compatibility is not acceptable in any of the three variants. In fact, the deviations from 40A to 40B to 40C result in worse performance.

Table 2 » Samples 40A-C.

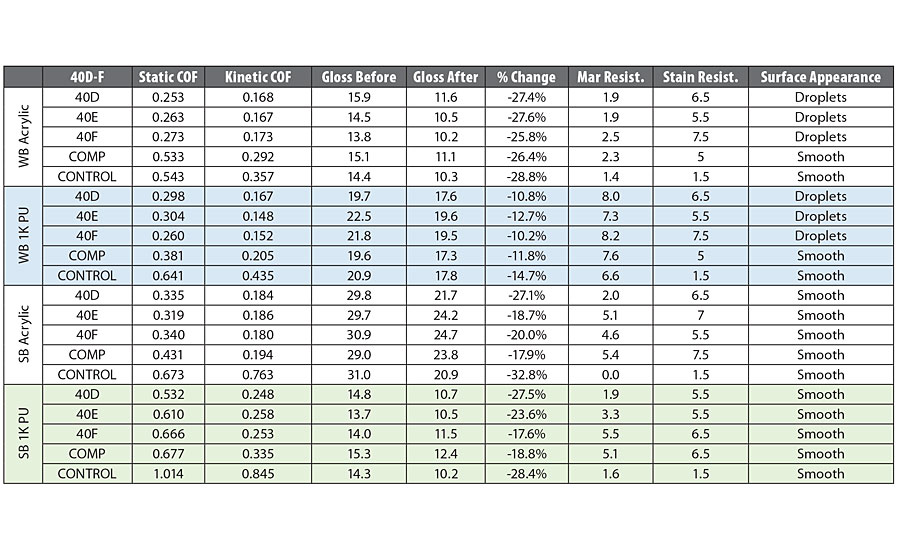

In this next set of variations, seen in Table 3, 40D, 40E and 40F show at least comparable and often better performance compared to the competitive offering. These samples are also much closer in compatibility in most formulations. However, significant differences in appearance are still seen in the 2K PU formulations.

Table 3 » Samples 40D-F.

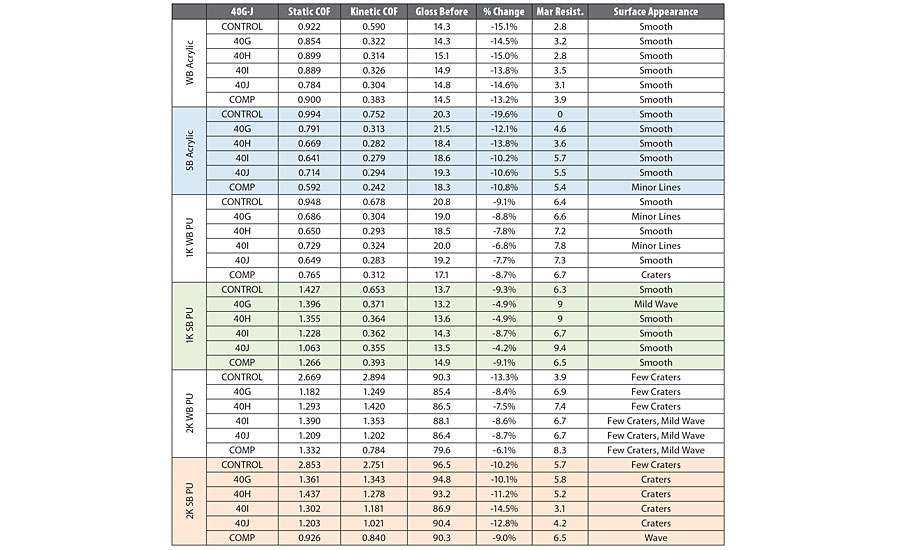

In this series of 40G-J, Table 4, we again see the now familiar pattern. Physical properties are very similar, and these variants are very close in compatibility.

Table 4 » Samples 40G-J.

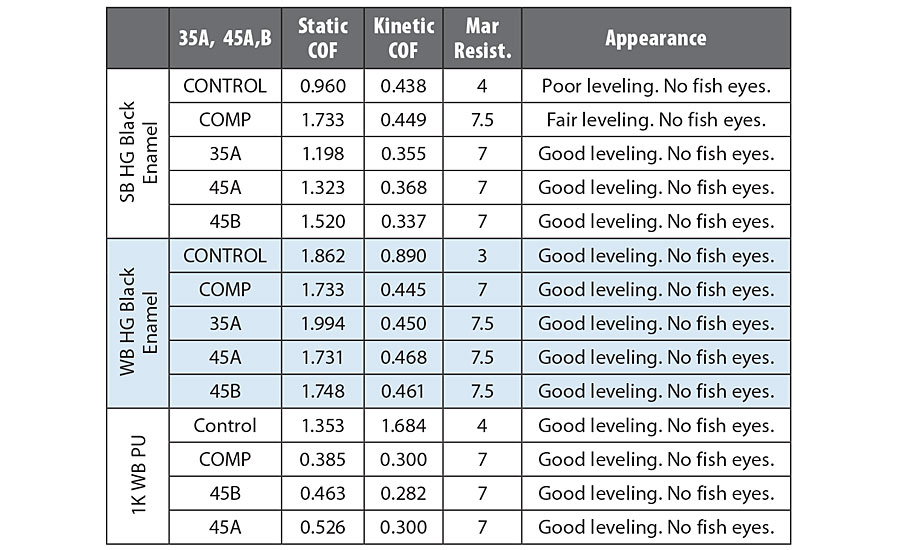

In the final series, seen in Table 5, Samples 35A, 45A and 45B are shown. These use an ultrahigh-molecular-weight silicone gum and no tin catalyst with unique dispersing packages. The two samples denoted 45A and 45B show especially good compatibility as indicated by leveling and lack of defects even over the competitive material in the SB test. Kinetic COF is as low as the samples labeled COMP.

Table 5 » Samples 35A and 45A-B.

Conclusion

As we progressed from the earliest structural variation we found it was straightforward to match the COF reduction and performance properties of the commercial silicone gum dispersions. Even compatibility in SB formulations was good in the early samples.

The trick was to improve waterborne compatibility, which we eventually accomplished primarily by altering the dispersion packages. In doing so, we found comparable, or in some formulations, superior performance to the target product.

Formulations

This paper was presented at the 2017 Waterborne Symposium. For more information, contact Bob Ruckle at Robert@siltech.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!