Deep Black Coatings without Milling

The performance requirements of specialty carbon black used for automotive basecoats are becoming increasingly stringent with regard to jetness and bluish undertone. First and foremost, the pigments must be stable in coating systems and must be highly resistant to weathering.

Orion Engineered Carbons has been offering specialty carbon blacks in powder and beaded forms for many years. These products are manufactured using the proprietary Degussa Gas Black process and are suitable for high-jetness use. Orion also uses the Furnace Black process to produce high-quality, high-color carbon blacks for the coatings industry. The company is the only manufacturer of both high-color Gas Blacks and high-color Furnace Blacks.

Pigment powders must be extensively dispersed to achieve satisfactory colorimetric properties. Fine-particle specialty carbon blacks have always been considered one of the most difficult pigments to disperse in coatings. They have very high surface areas, which result in very long grinding times with extensive energy input. In liquid coatings, powdered carbon blacks are typically used, as they are easier to grind compared to beaded carbon blacks. But powdered carbon blacks are very dusty and thus require a lot of cleaning in grinding facilities.

To overcome the drawbacks of powdered carbon blacks, Orion Engineered Carbons is developing carbon black-based pigment preparations that facilitate, and in many cases eliminate, the dispersion step. These preparations will be suited to both solvent- and waterborne applications, as well as both liquid and solid pigment preparations. We now offer a unique micro-beaded product dedicated to waterborne applications. Additional solventborne and universal grades, plus liquid dispersions, are in the R&D pipeline. We will report on these as soon as available.

Easily Dispersible Carbon Black

COLOUR BLACK OE 430 W is the first product in a new line of easily dispersible, “instant” carbon black preparations. It offers important advantages for the classical grinding process:

- It can be easily dispersed into water, providing very stable pigment pastes (mill bases) within minutes by using only a high-speed mixer.

- No milling or further wetting additives are needed. The wetting additive is already included in the solid preparation.

- A special dispersant provides excellent pigment stabilization and high jetness levels, combined with a strong bluish undertone.

- The 52.6% concentration is particularly high for a high-jet specialty carbon black dispersion dedicated to automotive OEM and other highly demanding applications.

- The free-flowing, micro-beaded product is easy to handle, creates practically no dust and offers very accurate dosing.

- This new carbon black preparation provides a very simple access to high-jet waterborne coatings. It can be dispersed directly in water, and develops final colorimetric properties typically between 30 and 60 min depending on the batch size.

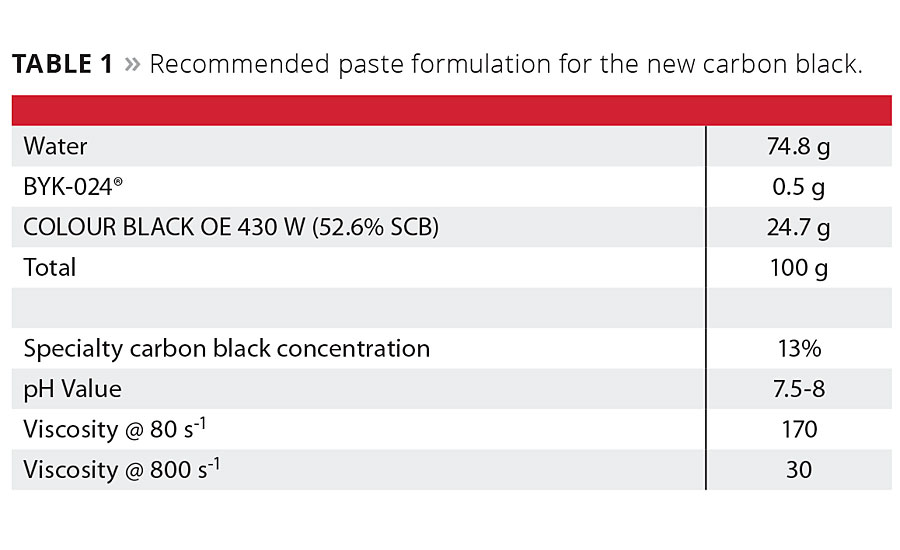

Table 1 details a typical waterborne, binder-free paste formulation with this new carbon black. A paste with 13% specialty carbon black is prepared by mixing COLOUR BLACK OE 430 W with water and defoamer using a high-speed mixer for 10 min. There is no longer a need for intensive milling with a media mill. Milling would only result in decomposition of the preparation and ingredients, and thus would worsen performance. Also, no further dispersion or wetting additives or surfactants need be added to the formula.

TABLE 1 » Recommended paste formulation for the new carbon black.

The obtained paste has a low viscosity and a fineness of grind below 10 µm. This concentrated paste is very stable in storage and can be letdown using standard waterborne binder systems, leading to high-gloss, high-jet coatings with strong bluish undertones and low haze.

Excellent Storage Stability

Pigment preparation discussions always include concerns of storage stability. Here solid pigment preparations offer a huge advantage compared to liquid preparations. Solid preparations – if stored correctly – have, in principle, an unlimited shelf life, as do powdered carbon blacks.

To test storage stability, COLOUR BLACK OE 430W as solid preparation and as a pigment paste (mill base) were stored at 40 °C for four weeks. No visual or measurable change in the quality could be detected in either the solid pigment preparation or the paste. Orion has experience with storage of solid pigment preparation exceeding two years with no issues occurring when the preparation was eventually dissolved into water.

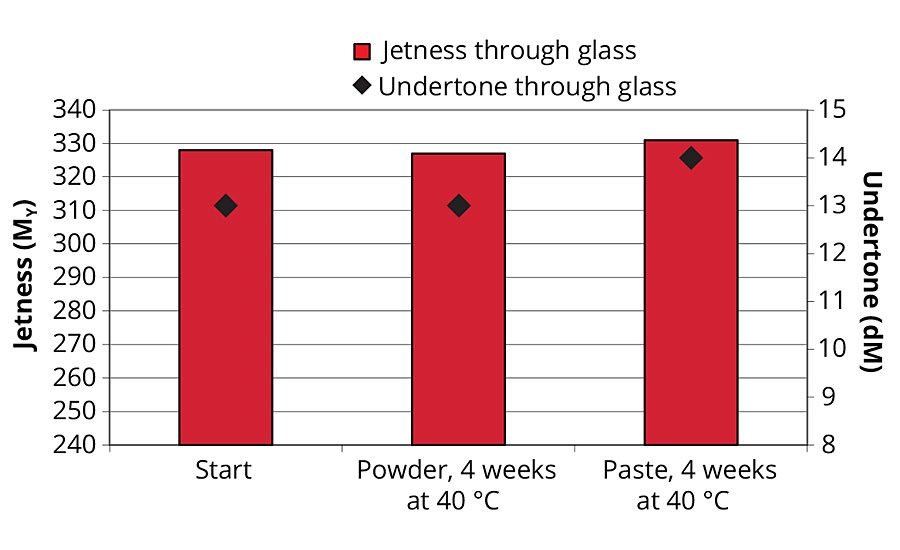

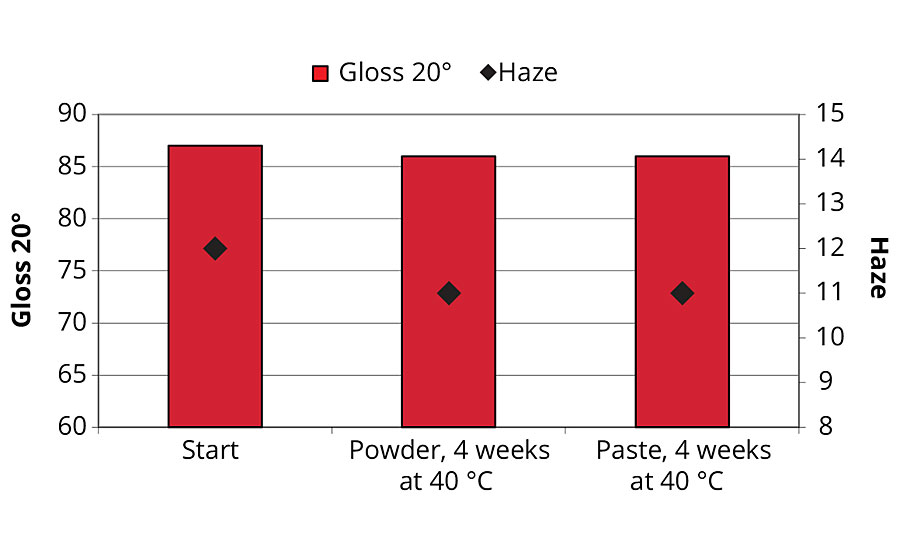

After performing the storage test, technicians prepared final coatings with a carbon black concentration of 1.5% (typical for automotive). We used a commercially available 30% PU dispersion (Alberdingk® U710, Alberdingk & Boley GmbH). The coatings were applied on glass plates (120 µm wet), flashed off for 15 min and force-dried at 80 °C for 30 min.

The colorimetric results are shown in Figures 1 and 2. All coatings provided highest jetness levels (MY 325 to 330), a strong bluish undertone, high gloss and low haze. No change in the colorimetric properties was identified after storage, which is evidence of excellent specialty carbon black stabilization in the preparation, the paste and the final coating.

FIGURE 1 » Colorimetric results of waterborne coatings based on COLOUR BLACK OE 430 W.

FIGURE 2 » Results for gloss and haze of waterborne coatings based on COLOUR BLACK OE 430 W.

Outstanding Colorimetric Performance

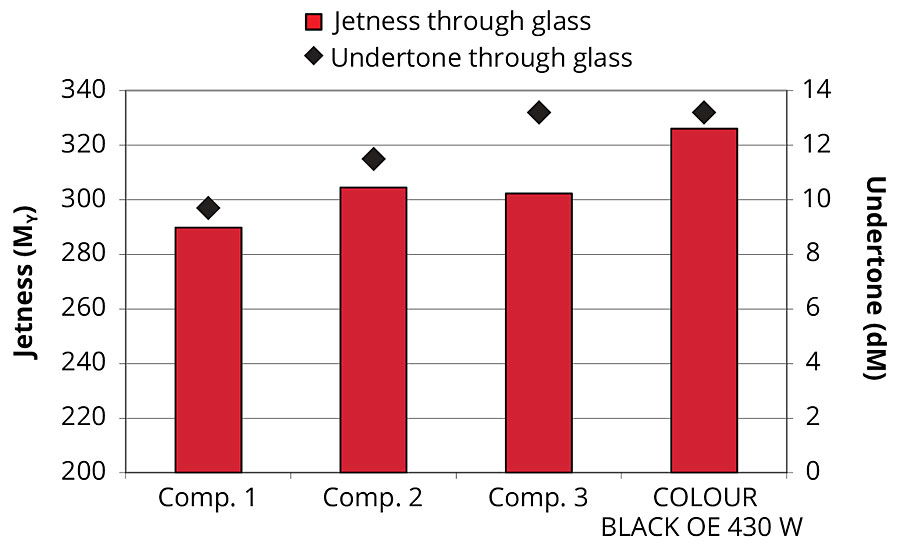

Figures 3 and 4 show the colorimetric results of COLOUR BLACK OE 430 W in comparison to several high-jet specialty carbon black powders. To prepare the coatings, the new carbon black pigment was dispersed within 10 min as described above to form a concentrated paste. Competitor specialty carbon blacks were prepared as follows: dispersion using 90% of active wetting agent relative to the specialty carbon black powders. A suitable additive is TEGO Dispers® 760W (Evonik Tego Chemie, 35% active).

FIGURE 3 » Colorimetric results of waterborne coatings based on COLOUR BLACK OE 430 W and several competitor specialty carbon blacks (stabilized with 90% active to pigment).

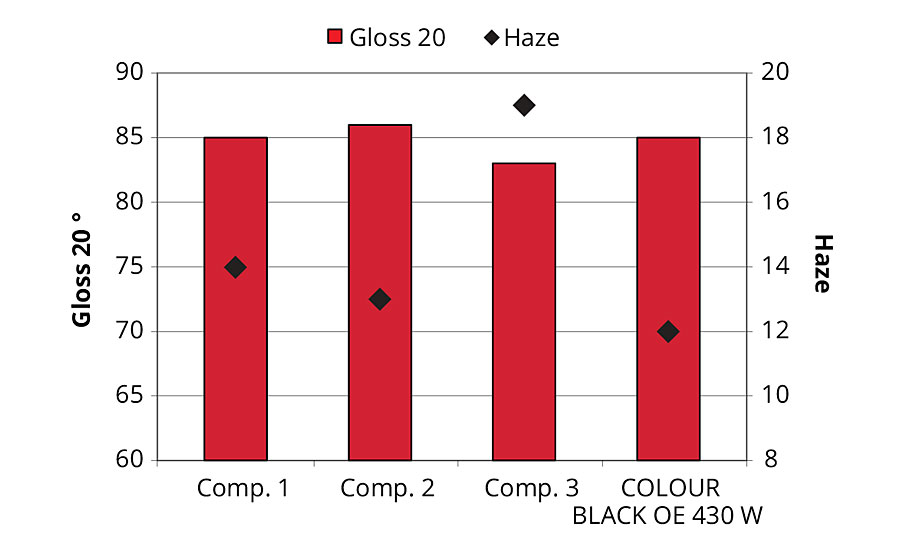

FIGURE 4 » Results for gloss and haze of waterborne coatings based on COLOUR BLACK OE 430 W and several competitor specialty carbon blacks (stabilized with 90% active to pigment).

After the initial wetting of the pigment using a mixer (5 min at a peripheral speed of 10 m/s), milling was done using a standard laboratory shaker, zirconium beads (1.0-1.6 mm) and a dispersing time of 1 hr. The viscosities of the mill bases were water-like. Fineness of grind was below 10 µm. The concentration of the specialty carbon blacks in the binder-free millbases was 13%.

Final coatings with a specialty carbon black concentration of 1.5% (typical for automotive) were prepared using a commercially available 30% PU dispersion (Alberdingk U710, Alberdingk & Boley GmbH). The coatings were applied on glass plates (120 µm wet), flashed off for 15 min and force-dried at 80 °C for 30 min. High-gloss, very low-haze coatings with highest jetness values combined with very strong bluish undertones were obtained for COLOUR BLACK OE 430 W. Its colorimetric property values exceeded those of even the best and extremely well-stabilized competitor specialty carbon black powders.

Cost Calculation

Looking at a solid pigment preparation from a cost/performance perspective might result in objections, but only at first glance. While doing sound cost calculations of the overall production process, we have seen many examples supporting the COLOUR BLACK OE 430 W approach. We have developed a cost calculation sheet to do a rough calculation. The higher price of our pigment preparation – compared to a pure carbon black – should take into account that there is no energy necessary for the main milling step. This energy input can be rather high, depending on the equipment and the desired results, with many hours or even days of necessary milling time.

Dispersion and wetting additives are also high cost factors. For high jetness carbon blacks, ratios of 70% to 120% solid on pigment are typical to achieve a good stabilization. These are no longer necessary. Cleaning times, using high-speed mixers only, can be reduced compared to bead mills. It is possible to increase flexibility in production due to shorter dispersion times. Even smaller batch sizes are easily processed instead of batch grinding once per month.

Coatings manufacturers should include all these factors, plus labor, in their calculations.

Summary

The coatings industry has evolved from the traditional grinding process to working with pigment preparations for quite some time. To support this trend, we have dedicated significant R&D efforts to develop easily dispersible pigment preparations solutions.

Our initial offering is COLOUR BLACK OE 430 W, a solid pigment preparation for use in environmentally friendly waterborne coatings. The results discussed above for this specialty carbon black preparation clearly prove that it is an outstanding product for coloring high-jetness black waterborne coatings.

The powder provides very fast and simple concentrated specialty carbon black pastes with broad compatibility. It generates practically no dust and no longer requires milling. Using this new carbon black, coatings formulators can obtain the highest jetness levels, very strong bluish undertones, high gloss and low haze.

Orion Engineered Carbons is developing comparable products for solvent-based systems and will present them soon. In addition, we will soon launch liquid preparations to provide coatings producers full flexibility in selecting the right product and delivery form for the greatest convenience.

For more information, visit www.orioncarbons.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!