Dispersible Polymer Powders for Biocide-Free Wall Paints

Most liquid wall paints today are waterborne. When used in paints, however, water provides a favorable environment for bacteria and other microbes. In order to prevent the growth of these organisms, the paints are typically formulated with biocides to make them last longer. According to the German Paint and Printing Inks Industry Association, one in four buckets of paint will spoil unless preservatives are added. That translates to eleven million buckets per year, at a cost of ?470 million.1

There is a problem with biocide use, however: once the paint has been applied to the wall and begins to dry, liquid components evaporate, allowing biocides to escape into the air. Biocides, especially isothiazolinones, can trigger allergic reactions in some people.

WACKER has created a technology for the production of biocide-free wall paints. At the 2019 European Coatings Show, the Group presented a product line based on spray-dried polymeric binders suitable for producing interior wall paints in either liquid or powder form. Paint manufacturers can use the polymer binders to create individual paint formulations, just as they can with traditional binders in dispersion form.

Paints formulated with the new binders can be used by professional and do-it-yourself (DIY) painters. Initial market feedback confirms the high quality of these paints, especially regarding hiding power and wet-scrub resistance.

Categories of Powder Paints

The concept of powder paints is not entirely new. There are several categories of powder paints, of which some have been used for a long time in human history. Mineral paints like clay paints, cement powder paints, lime powder paints or silicate powder paints work with mineral binding agents such as cement, mud or loam, soluble water glass or hydrated lime. These paints are known for their good breathability. However, they show several disadvantages compared to paints that use polymeric binders.

Clay and cement powder paints, for example, are rather hard to apply as they do not provide a good coating quality or hiding power. Additionally, they require an expert level in application technique to avoid stain formation. This is also why cement powder paints are often used in basements, but not as decorative coatings. Silicate powder paints have good hiding power, but generally come as two-component systems.

Usually, mineral powder paints like these are highly alkaline, which makes it hard to combine them with polymeric binders to enhance their performance. However, polymer binders offer several advantages in paints such as easy application, high variety in formulations, excellent hiding power and wet-scrub resistance. Additionally, binders based on dispersible polymer powder enable manufacturers to formulate paints in powder form in the sophisticated decorative color segment that requires high-quality paints.

Dispersible polymer powder is produced in an integrated production process: acetic acid and ethylene are used to produce vinyl acetate monomer, VAM. In a copolymerization process, VAM and ethylene transform to vinyl acetate-ethylene, VAE. The liquid dispersion and a protective colloid run through a spray dryer. The protective colloid matrix separates the dispersion particles in the powder particles from one another and prevents the polymer particles from irreversibly forming a film during drying and storage. Upon addition of water, the dispersible polymer powder is readily re-dispersed into individual particles.

Flexibility in Formulation

Dispersible polymer powder offers a very flexible method of producing decorative and high-quality paints. During the production process, paint manufacturers can decide at which stage water should be added to the formulation.

One possibility is to add water at an early stage of the process: the dispersible polymer powder is re-dispersed in water to obtain a conventional liquid dispersion. The advantage here: manufacturers can use the biocides or additives they prefer and do not depend on those added by the dispersion supplier.

A second approach is to produce paints in powder form and deliver them directly to distributors such as hardware stores or DIY markets where the powder paint can easily be stored. Water can then be added upon customer request to mix the paint. Even the amount of paint can be adapted to individual customer needs.

Another possibility is to produce powder paints and sell them to the end user. In this approach, end consumers buy their powder paint at the hardware store or specialist painter’s shop, for example. At home or on the construction site, they can add water to produce the specific amount of paint they need – either to cover a small stain or to paint an entire wall.

To prepare a standard quantity such as a 10-liter bucket of the final product, end users start with the water, add the powder and mix it for approximately five minutes with a drilling machine. For smaller quantities of approximately one liter or less, shaking is sufficient to ensure good mixing.

Wet-Scrub Resistance and Hiding Power

Intensive testing shows that paints produced with dispersible polymer powder perform to a high quality standard. One important criterion of paint is hiding power. To determine this value, lab technicians took opacity sheets, weighed them and measured their density with a cup pycnometer. After that, two paint films, one with 150 µm and the other with 225 µm, were cast. The opacity sheets were weighed again after casting. The film was then dried for 24 hrs at a temperature of 23 °C and 50% humidity. After the drying time, the opacity was measured with special equipment intended for this measurement. In a next step, all results were used to calculate the contrast ratio. According to ISO 6504-3, there are four classes for the hiding power of paints, ranging from class 1 with the highest hiding power (contrast ratio ≥ 99.5) to class 4 with the lowest hiding power (contrast ratio of < 95). Powder paints formulated with dispersible polymer powder reach a contrast ratio between 98 and < 99.5 and thus achieve class 2 in hiding power.

Another major criterion for the performance of decorative interior wall paint is wet-scrub resistance. This was tested at the WACKER labs in accordance with ISO 11998. In a first step, a paint film was cast on a PVC sheet with 300 µm. The sheet then dried for 72 hrs in standard atmosphere, followed by 24 hrs at 50 °C and another 24 hrs in standard atmosphere. After that, the thickness of the PVC sheet with and without the dry paint was measured. The sheet was then cut into several stripes and each stripe was put on a special machine that slides a sleigh with a fleece pad over the painted surface for 200 cycles. Afterwards, the PVC samples were measured again. ISO 11998 defines five classes with class 1 being the highest at <5 µm loss after 200 cycles and class 5 being the lowest at >70 µm loss after 40 cycles. Results show that a standard paint formulated with dispersible polymer powder fulfils requirements for class 2 (>5 µm to <20 µm loss after 200 cycles).

Biocide-Free, Low-VOC, Ecolabel-Compliant

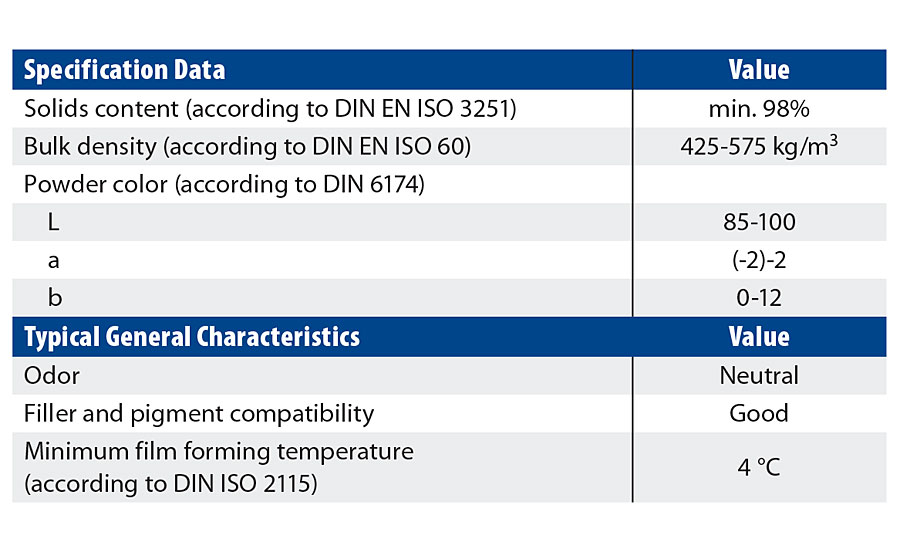

Powder paints with dispersible polymer powder are low-odor and remain stable, even without the addition of preservatives. Depending on manufacturer and customer preferences, water for re-dispersing the paints does not have to be added until just prior to application, thus eliminating the need for adding biocides during production. Powder paints based on dispersible polymer powder also have a longer shelf life than regular dispersion paints. They can be formulated to have a very low volatile organic compound (VOC) content (<1 g/L) and conform to major ecolabels. Specifications for a standard dispersible polymer powder are shown in Table 1.

Paint formulated with dispersible polymer powder does not need organic solvents, plasticizers or film-forming agents, as the film forming temperature is at approximately 0°C. Additionally, the polymer powder supports the dispersion of fillers and pigments and thus enhances the hiding power and spreadability of the paint.

Storage, Transport and Preparation

Another advantage is that powder paints can be prepared on demand at a precise dosage, which avoids the amount of wasted product. They are also easier to transport and store than dispersion paints. Typical formulations have a weight saving of 40% compared to dispersion paints. Furthermore, powder paints can be packaged differently than liquid paints: they can be kept in bags, providing better use of space during transport and storage, and the dry form is much safer in case of packaging damage or leakage during transport.

Powder paints can be stored even under challenging climatic conditions. Unlike traditional wall paints, powdered versions do not freeze in the cold, nor do they thicken when exposed to heat. However, prolonged storage at temperatures above 30 °C, including in combination with pressure load, humidity or exposure to sunlight, may result in blocking. To protect the powder from contact with moisture, it is recommended to use polyethylene inlets in packaging as they have low moisture permeability.

Dispersible polymer powder also enables fast paint preparation. The polymer particles easily disperse in water. Thus, the paint can be applied immediately after mixing, unlike other powder paints that require time to swell before they are ready to use.

The consistency of the paint can be adjusted via the ratio between water and powder, i.e. painters can decide whether they want a thinner or thicker paint, depending on their individual painting project. For standard formulations, we have defined a recommended ratio of 150 g per 100 mL of water.

Summary

Most liquid wall paints today are waterborne. However, water provides a favorable environment for microbes and bacteria. To prevent the growth of these organisms, the paints are typically formulated with biocides to make them last longer. WACKER has developed a dispersible polymer powder that allows manufacturers to formulate interior wall paints in powder form. The technology does not require the addition of biocides and offers key advantages when it comes to storing and transporting paints.

For more information, visit www.wacker.com.

References

1 http://www.wirsindfarbe.de/presse/lacke-farben-aktuell/farben-brauchen-schutz/ (German-language website only)

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!